Portable Panel Saw System PSS 3100 SE - GB, 110 V

- 1 TCT saw blade 160 x 1.2/1.8 x 20 mm (6 5/16 in.), AT, 24 teeth

- 1 Allen key 5 mm; Ref. No. 093278

- boxed

Technical data

| Universal motor | 110 V |

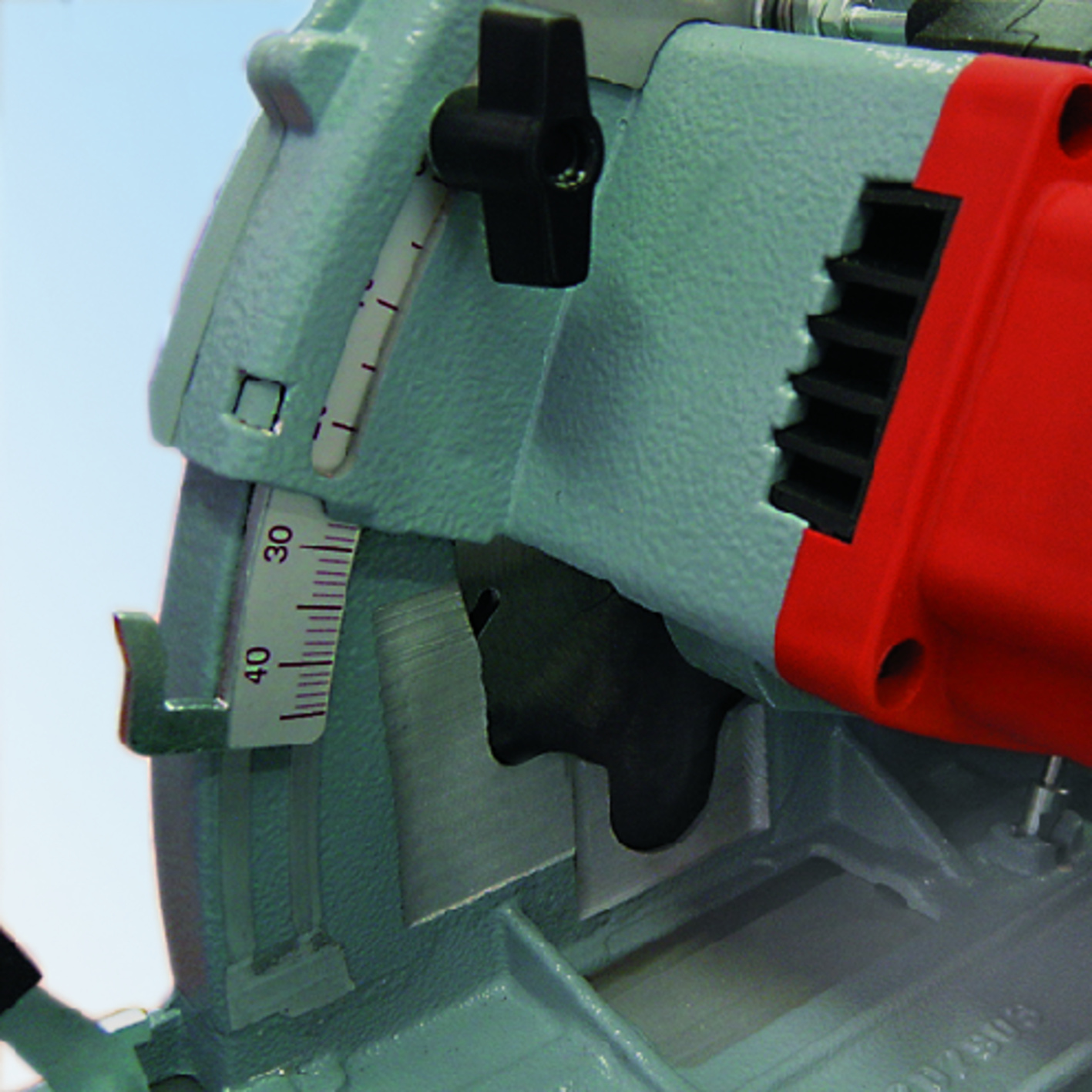

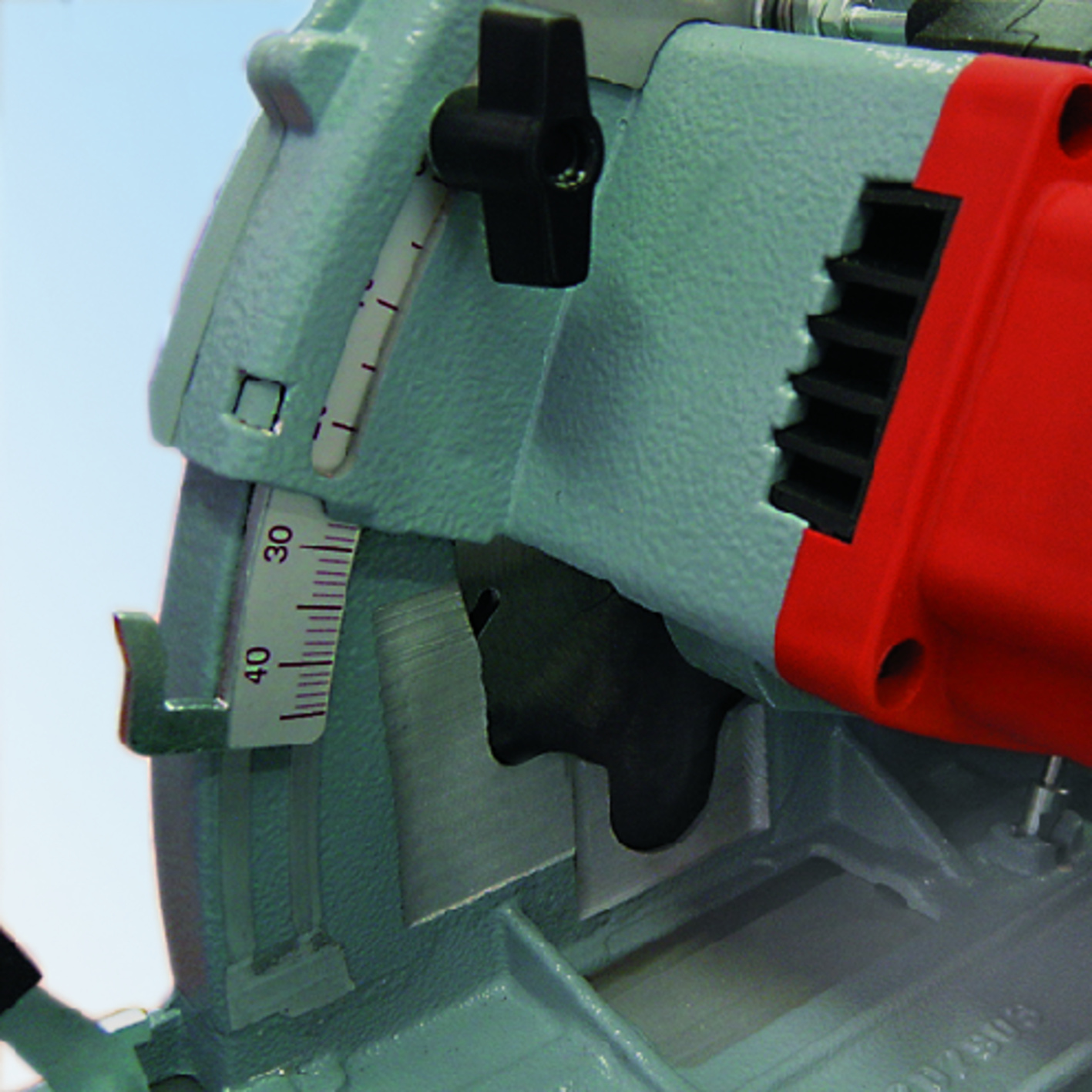

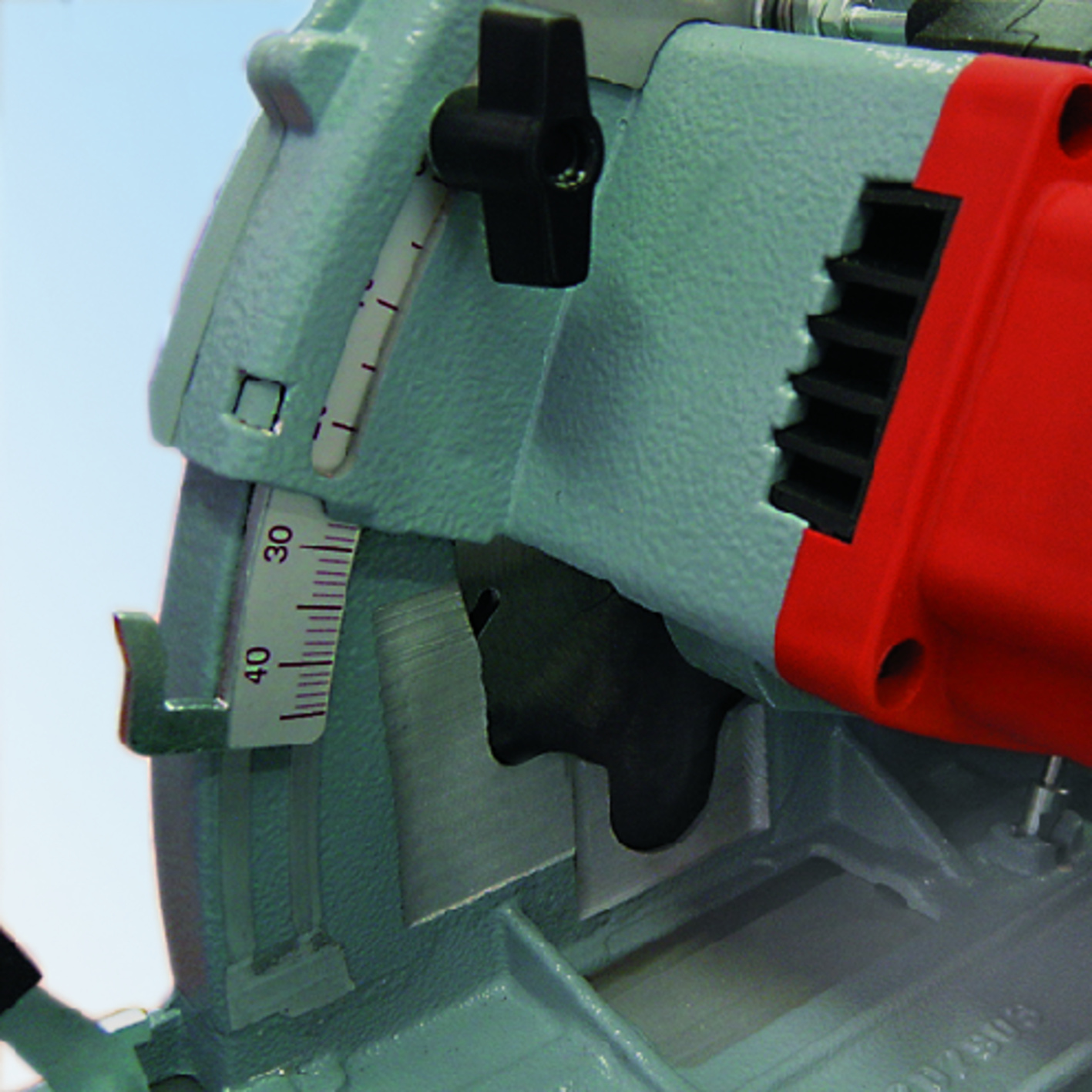

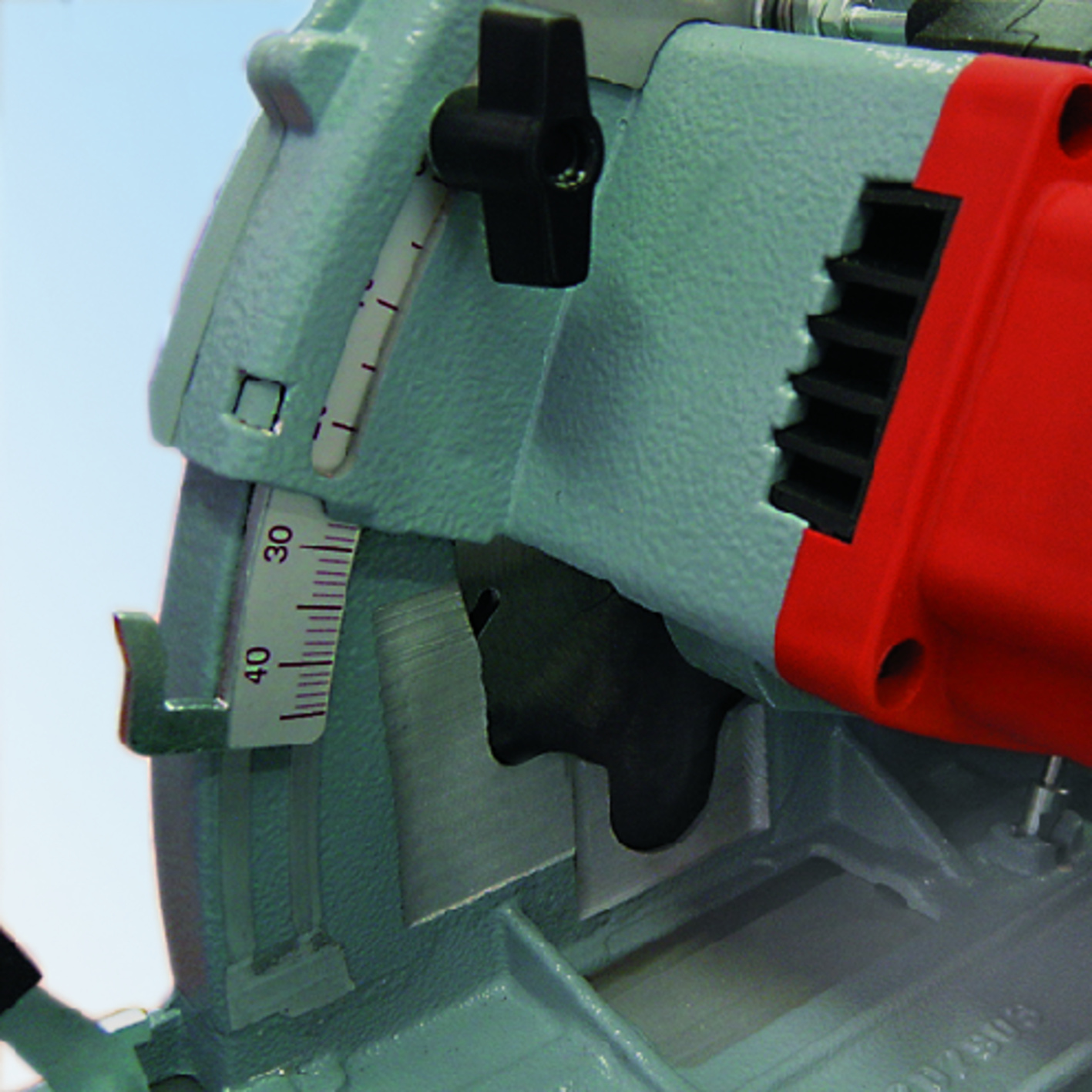

| Cutting depth | 0 - 45 mm |

| Cutting depth | 0 - 3 1/4 in |

| Cutting depth (a) | 0 mm |

| Cutting depth (b) | 45 mm |

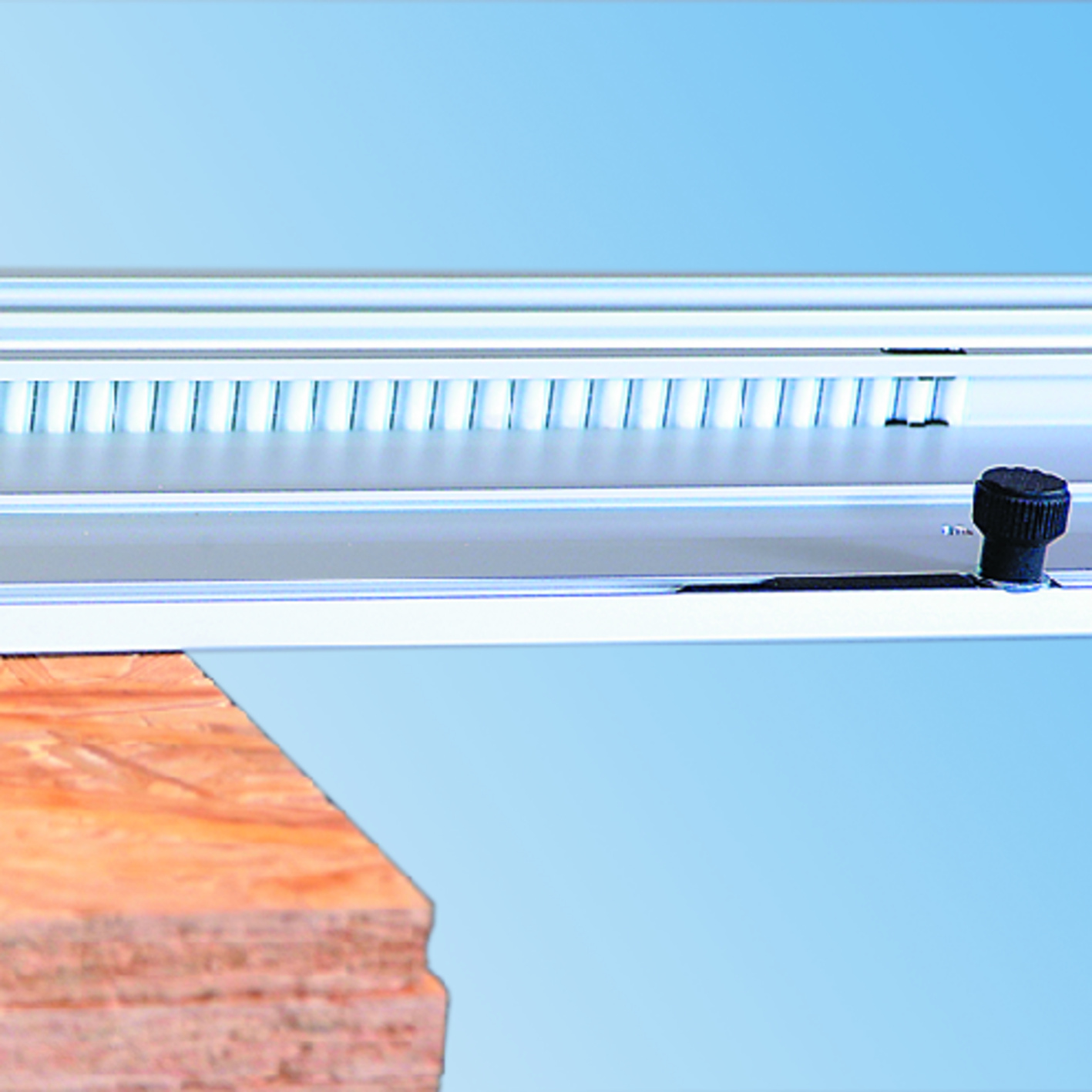

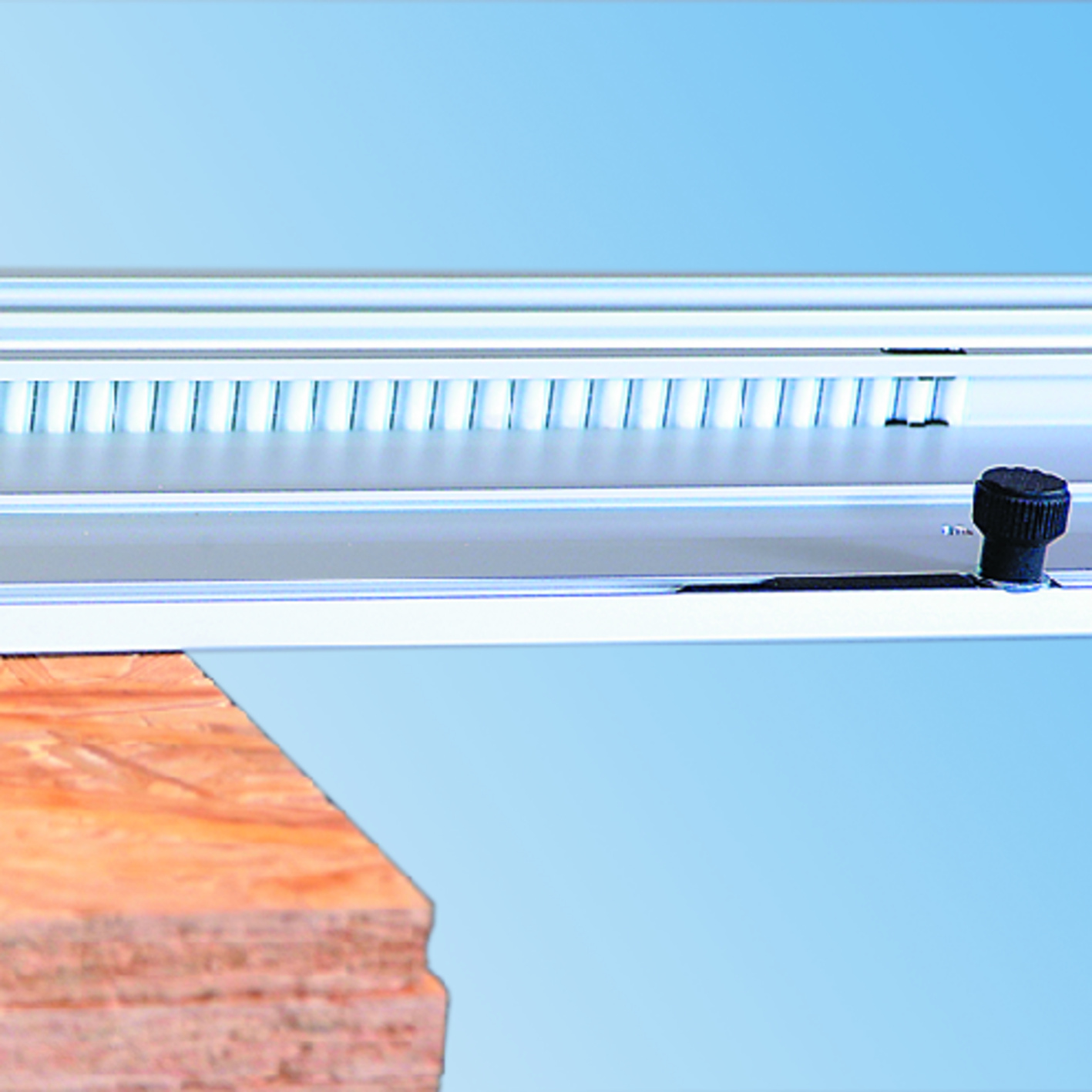

| Cutting length | 3100 mm |

| Cutting length | 122 1/16 in |

| Feed rate speed | 0,07 - 0,34 m/s |

| Feed rate speed | 0.2 - 1.1 ft/s |

| Nominal No. of strokes – no load | 2600-5200 1/min |

| Nominal power input | 1490 W |

| Nominal power input | 2.0 hp |

| Weight | 18,3 kg |

| Weight | 40.3 lbs |

Product details

The PSS 3100 SE from MAFELL is the world's first self-driven, rail-guided and mobile panel saw.

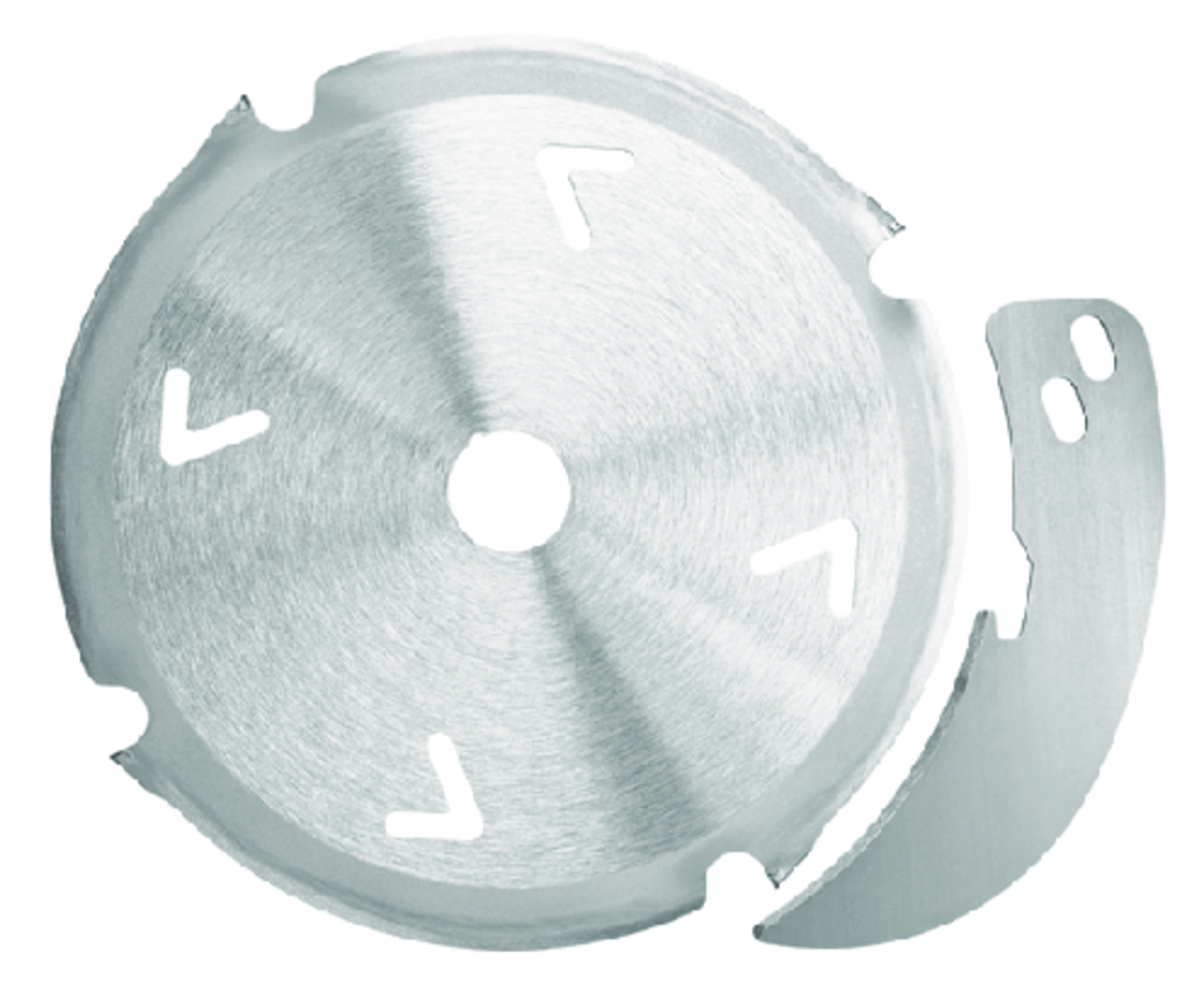

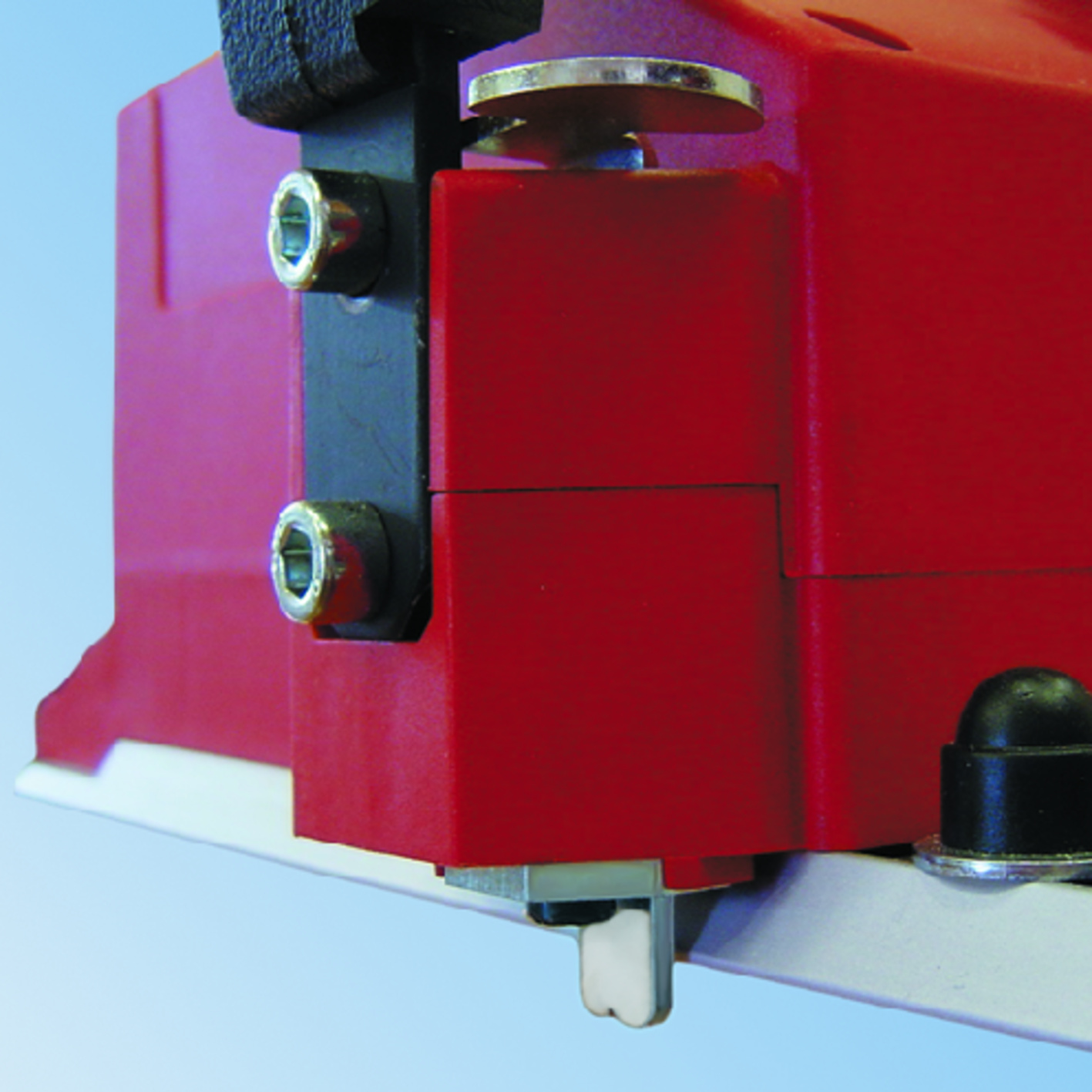

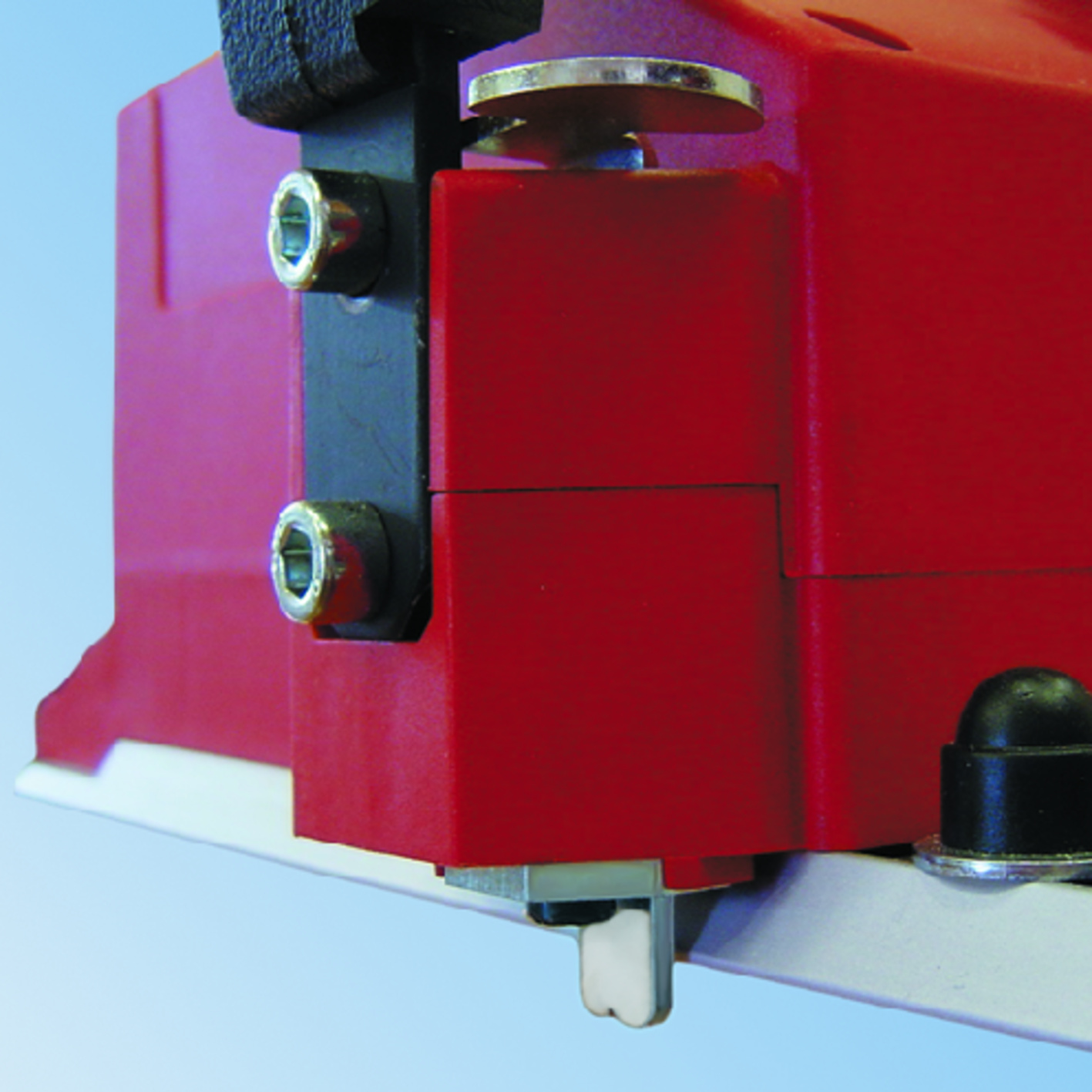

Unique design features ensure that hardly any dust escapes during operation. The PSS 3100 SE disposes of an innovative full-size shroud for the saw blade. In conjunction with the integrated suction channel and the S 50 M, it eliminates practically all of the dust particles that occur.

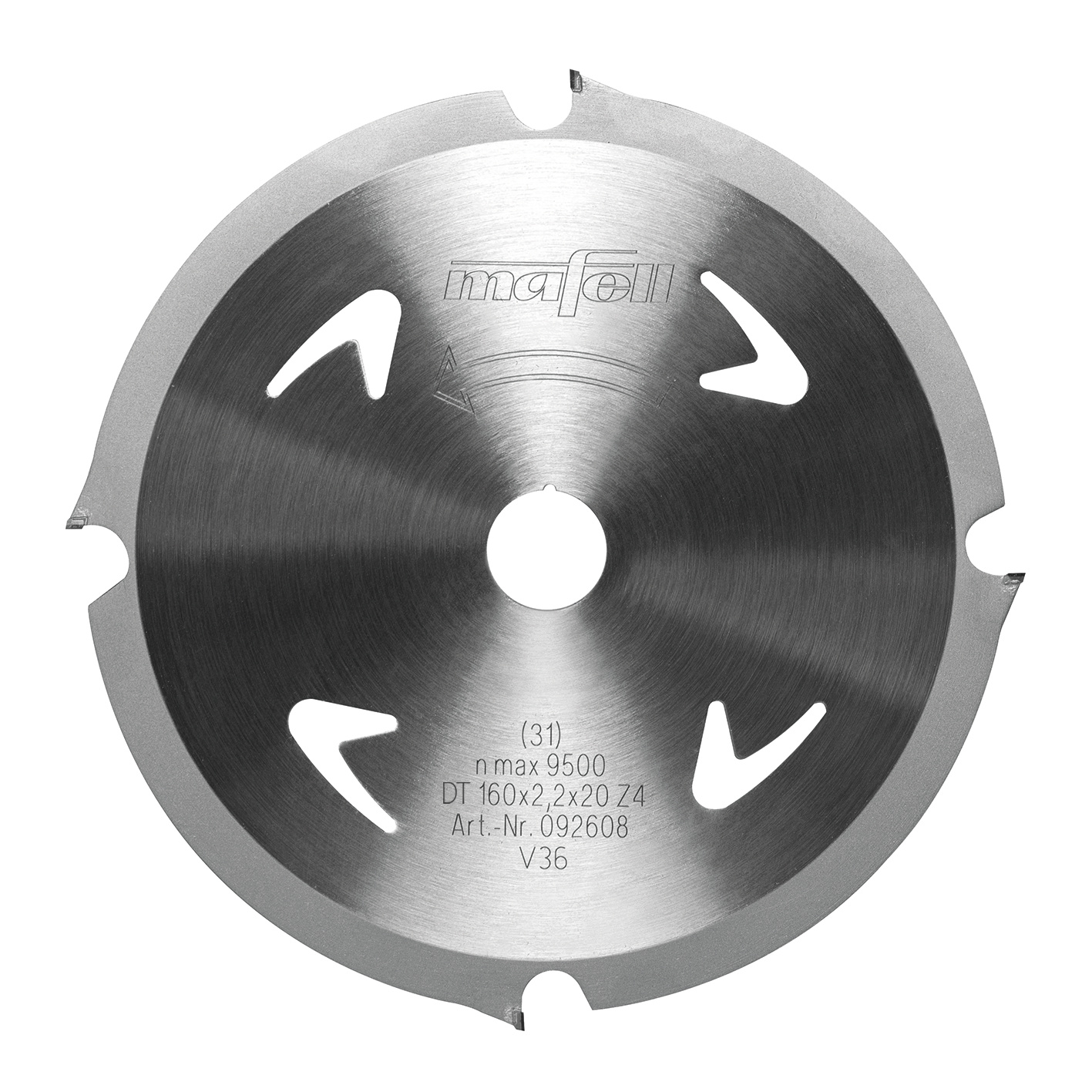

With MAFELL's newly developed diamond saw blade, the PSS 3100 SE is well equipped for use with mineral containing materials including cement fiber panels.

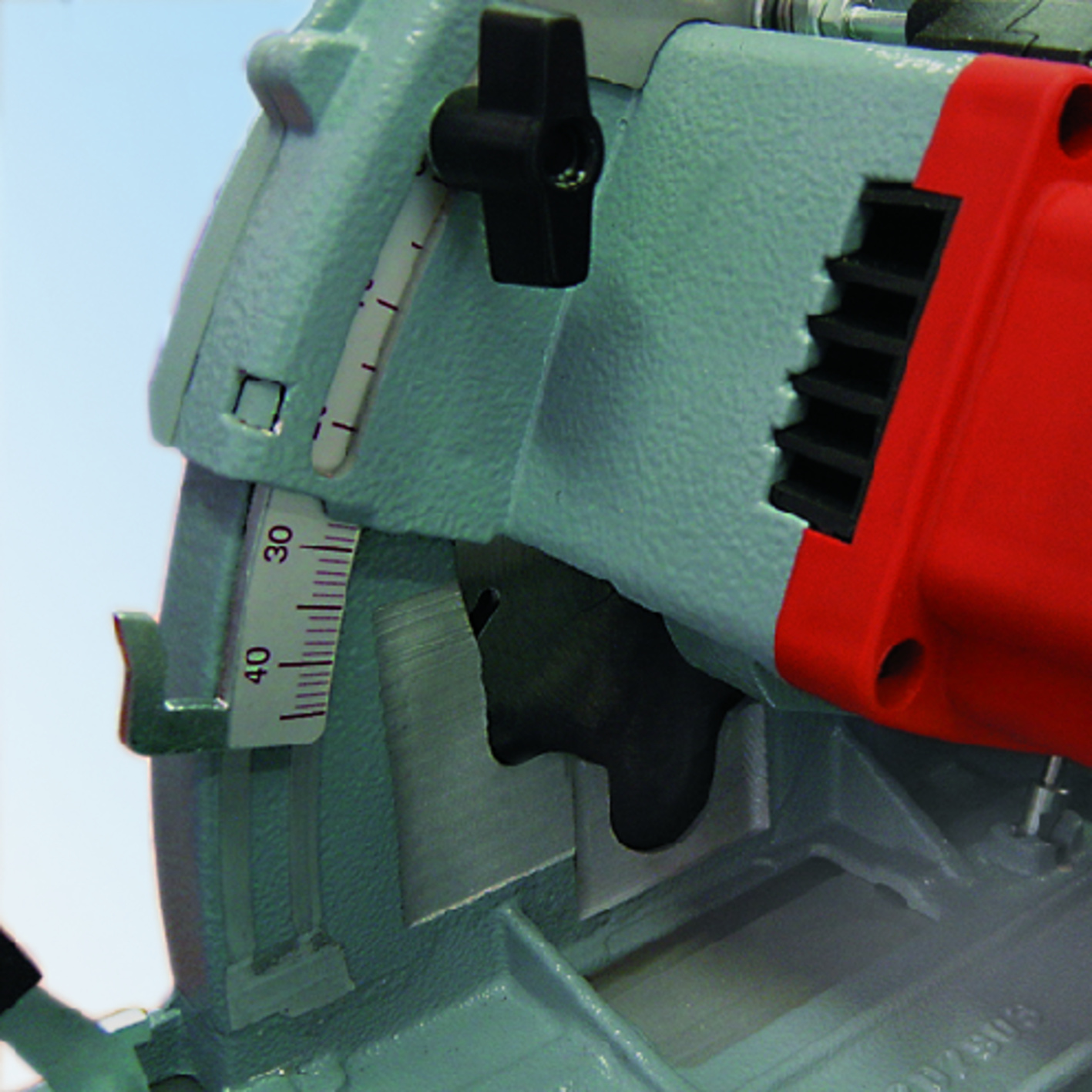

Full-wave electronics with speed adjustment and smooth starting improve safety and allow the speed to be adjusted for various materials, including plastics. The electronics also ensure constant speed under load and protect the machine against overloading.

Applications

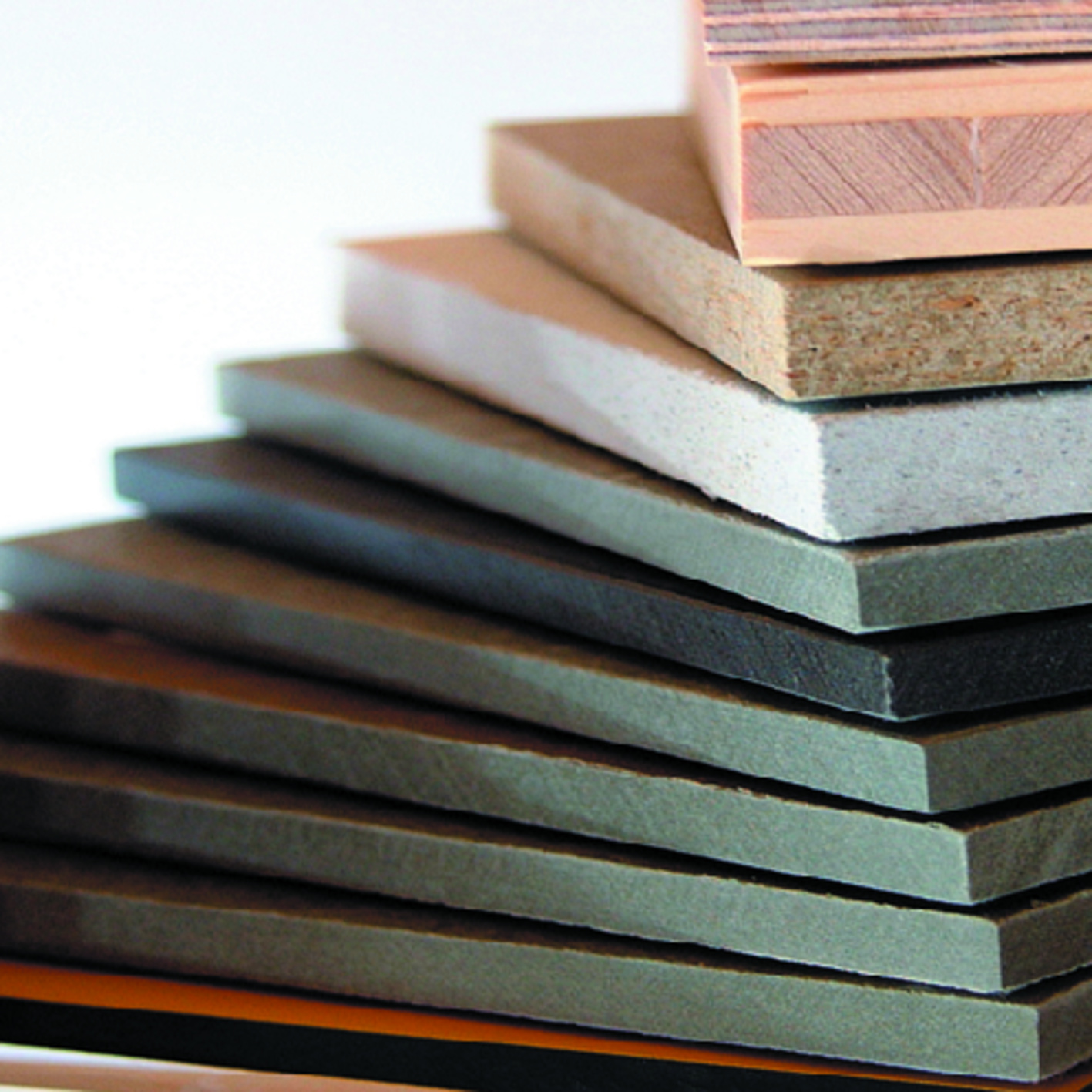

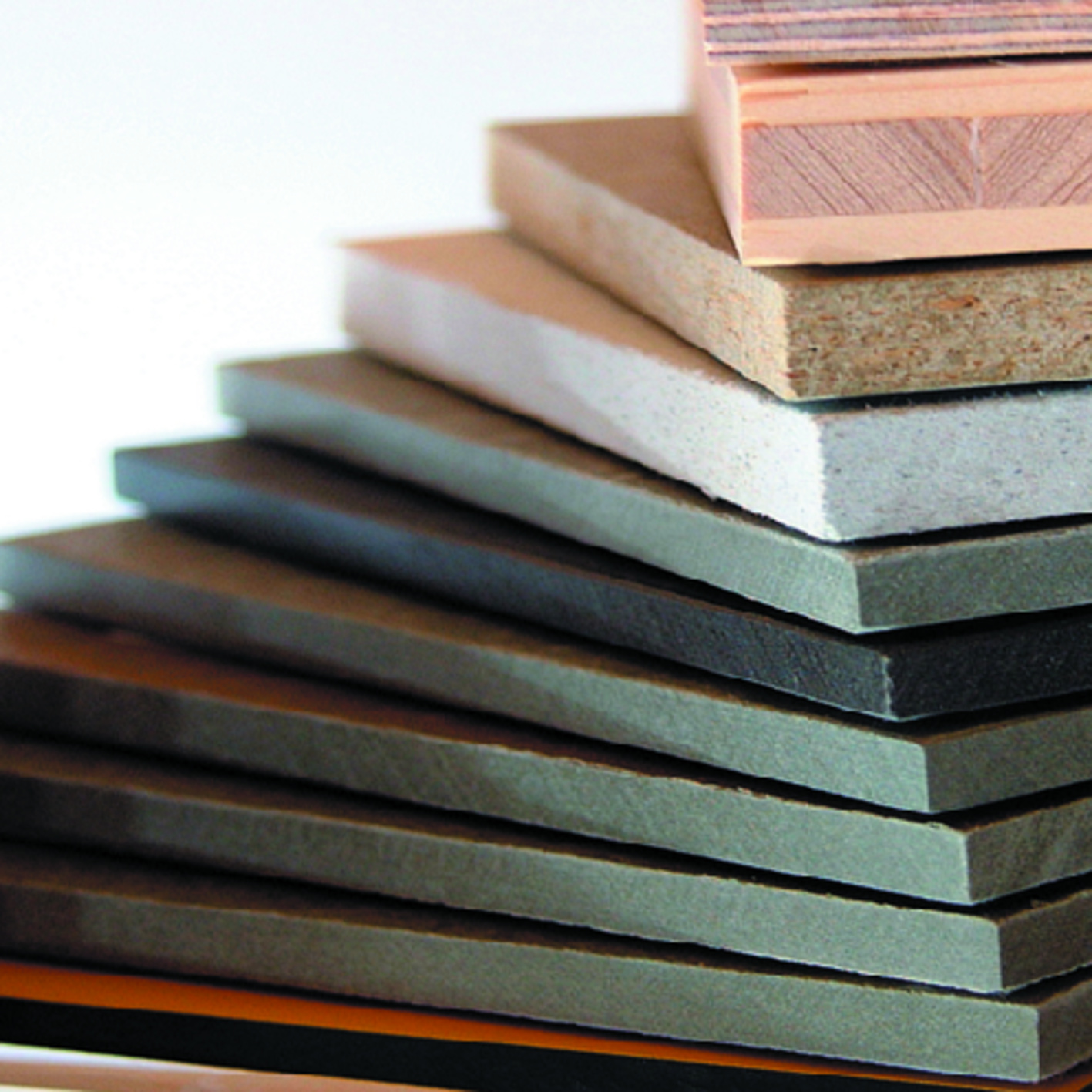

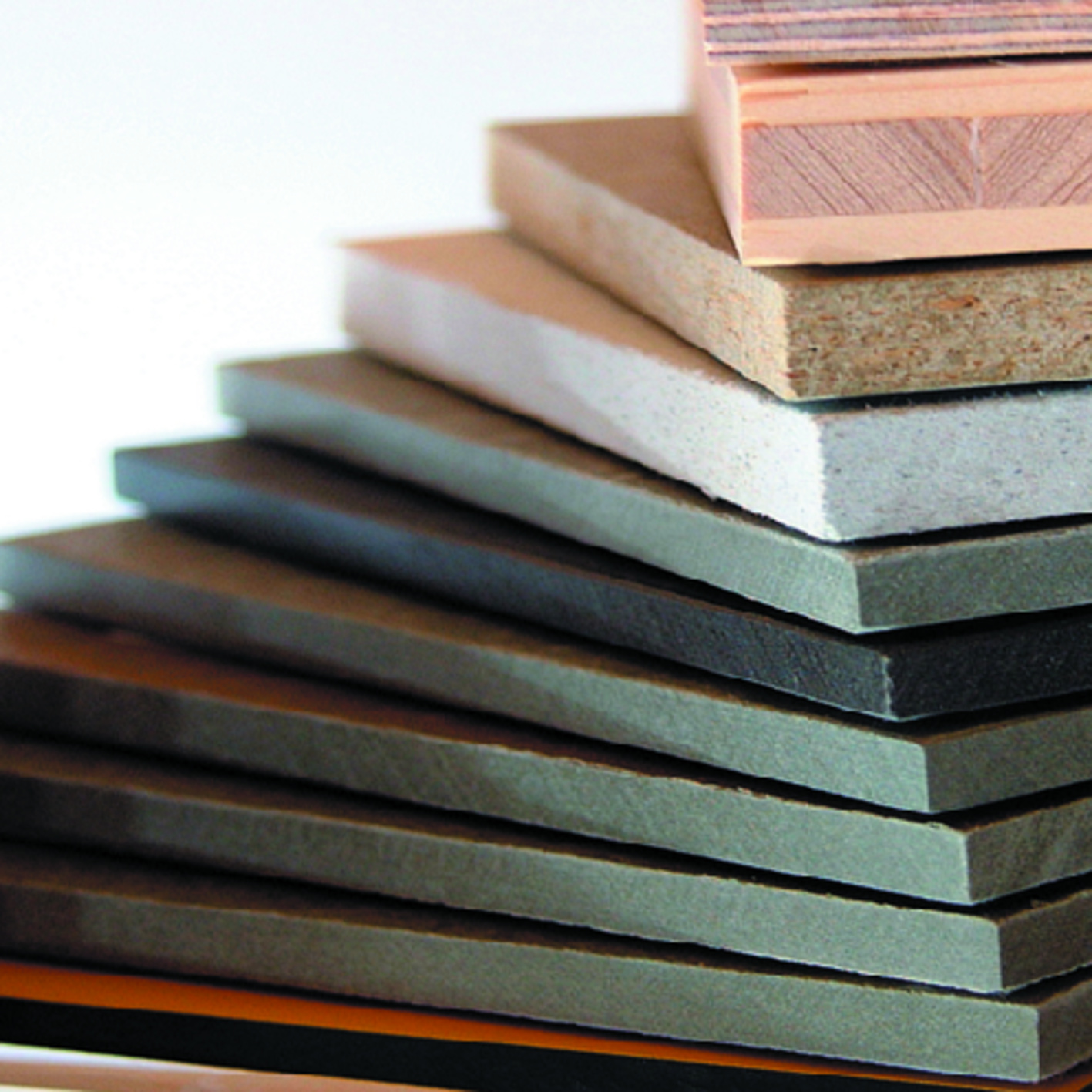

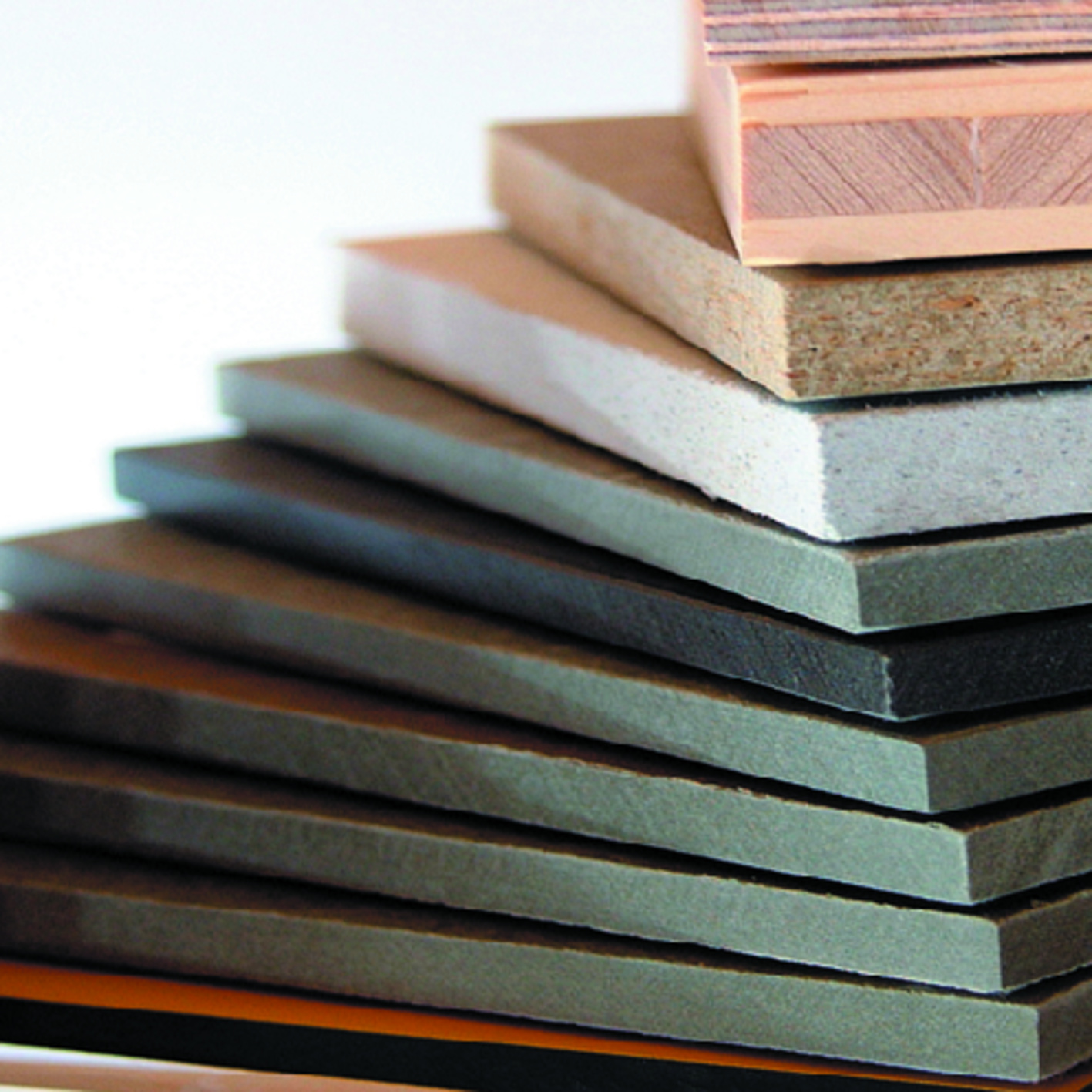

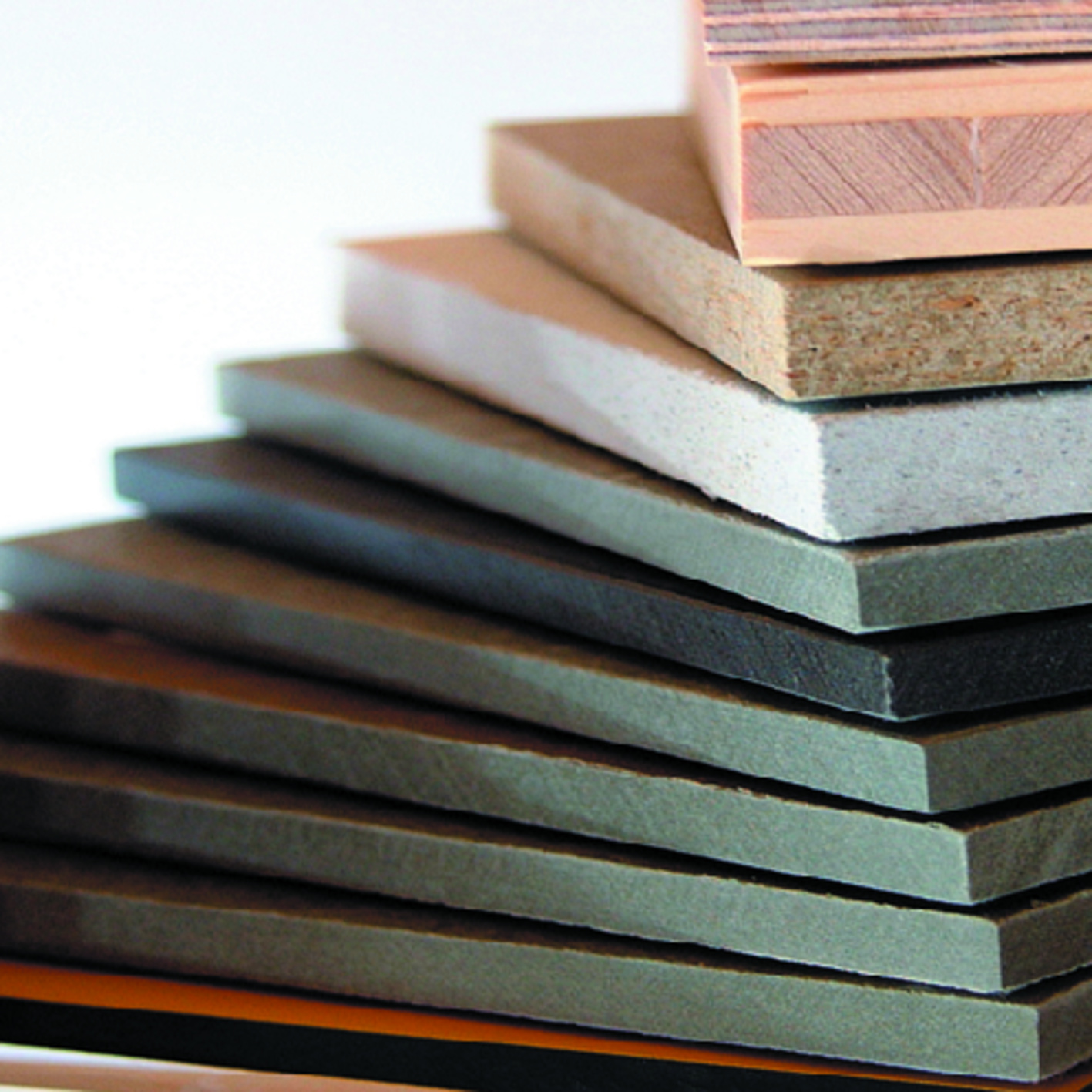

- Machining and cutting to size of board materials (e.g. timber frame construction)

- Compatible materials include cement and gypsum fiberboard, plastics, OSB, façade boards, melamine resin panels (Trespa)

Advantages

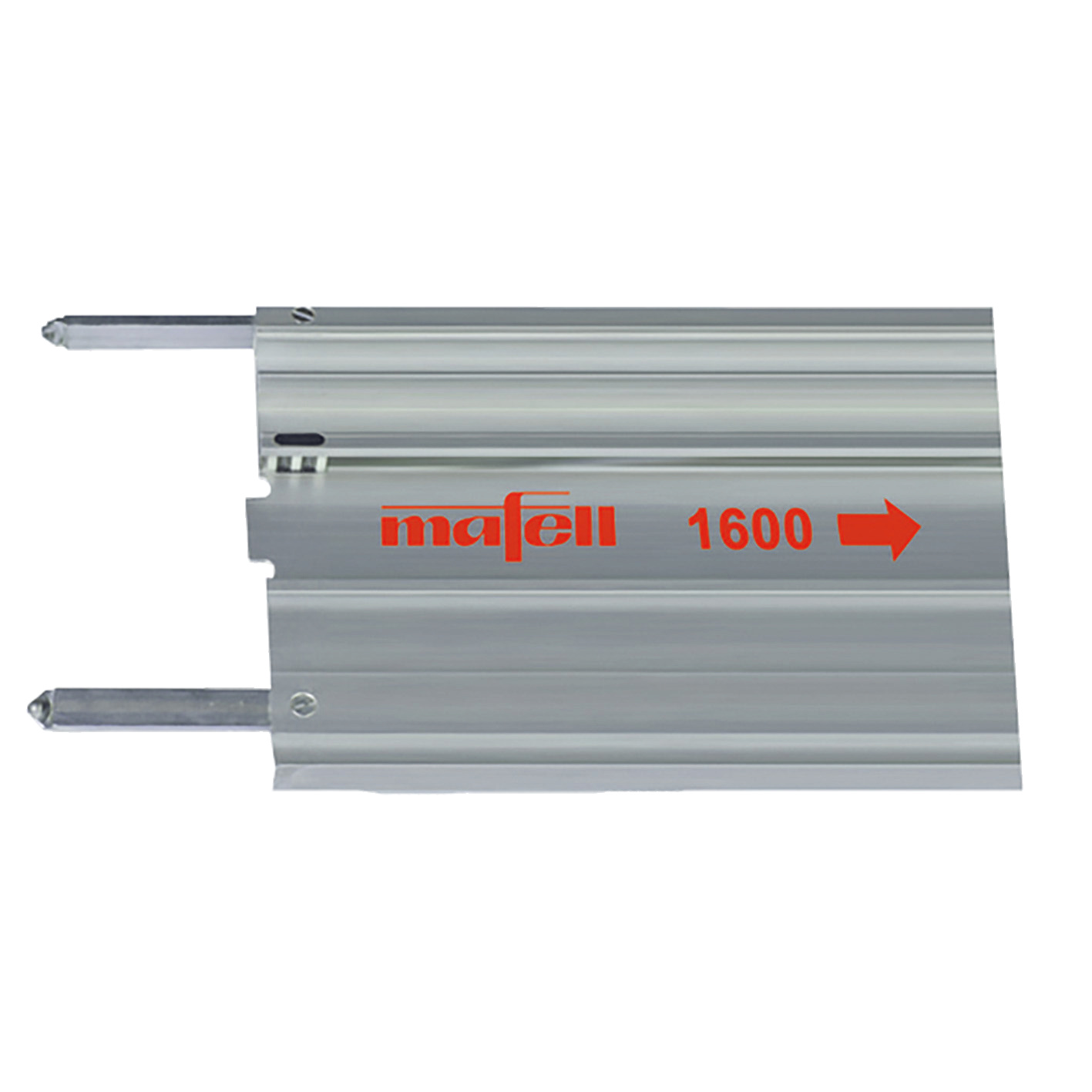

- Follow-on fence for panel formats over 3100 mm (122 1/16 in.)

- Suitable for plunge cuts with the MAFELL-FLIPPKEIL.

- Considerable price and handling advantages compared to stationary panel saws.

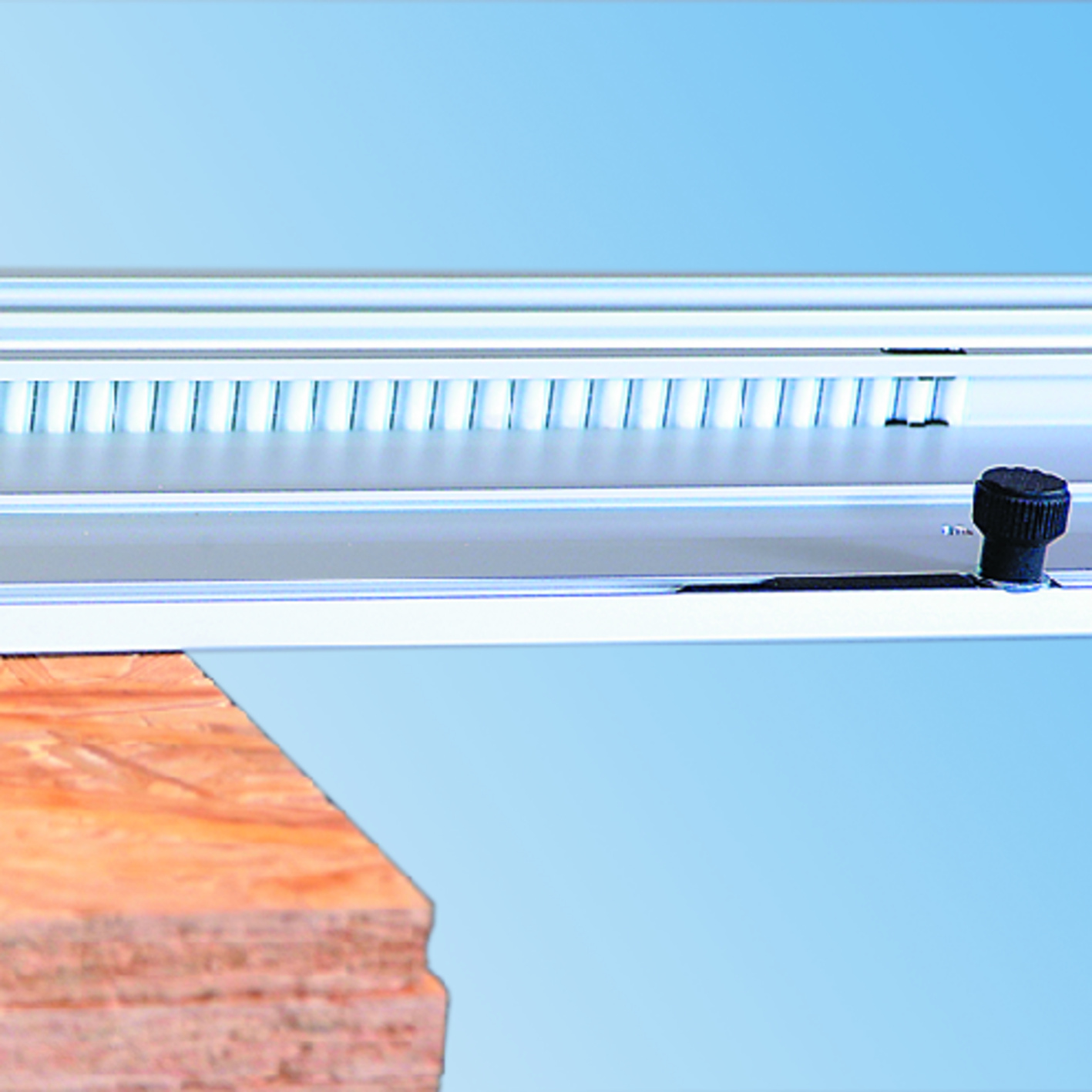

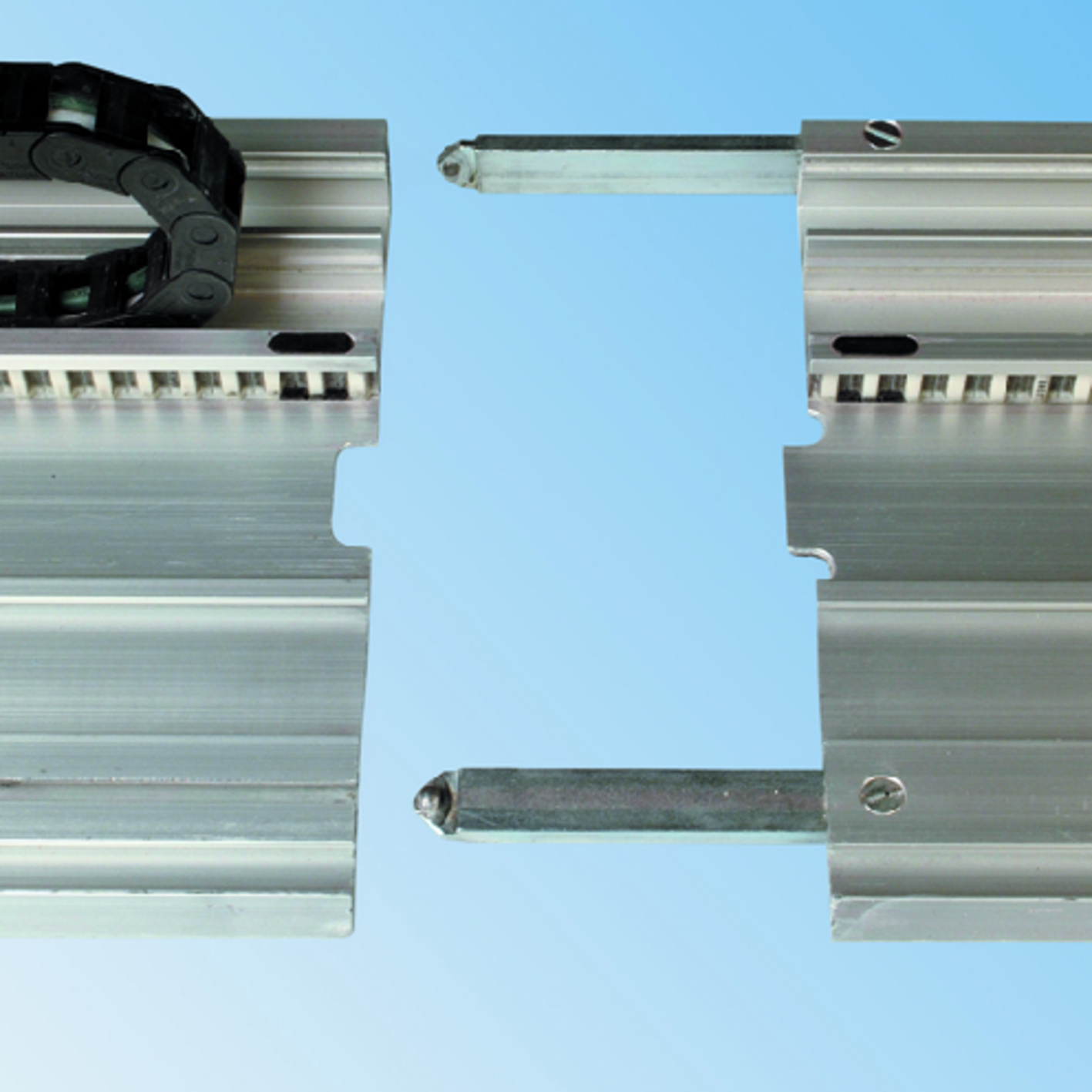

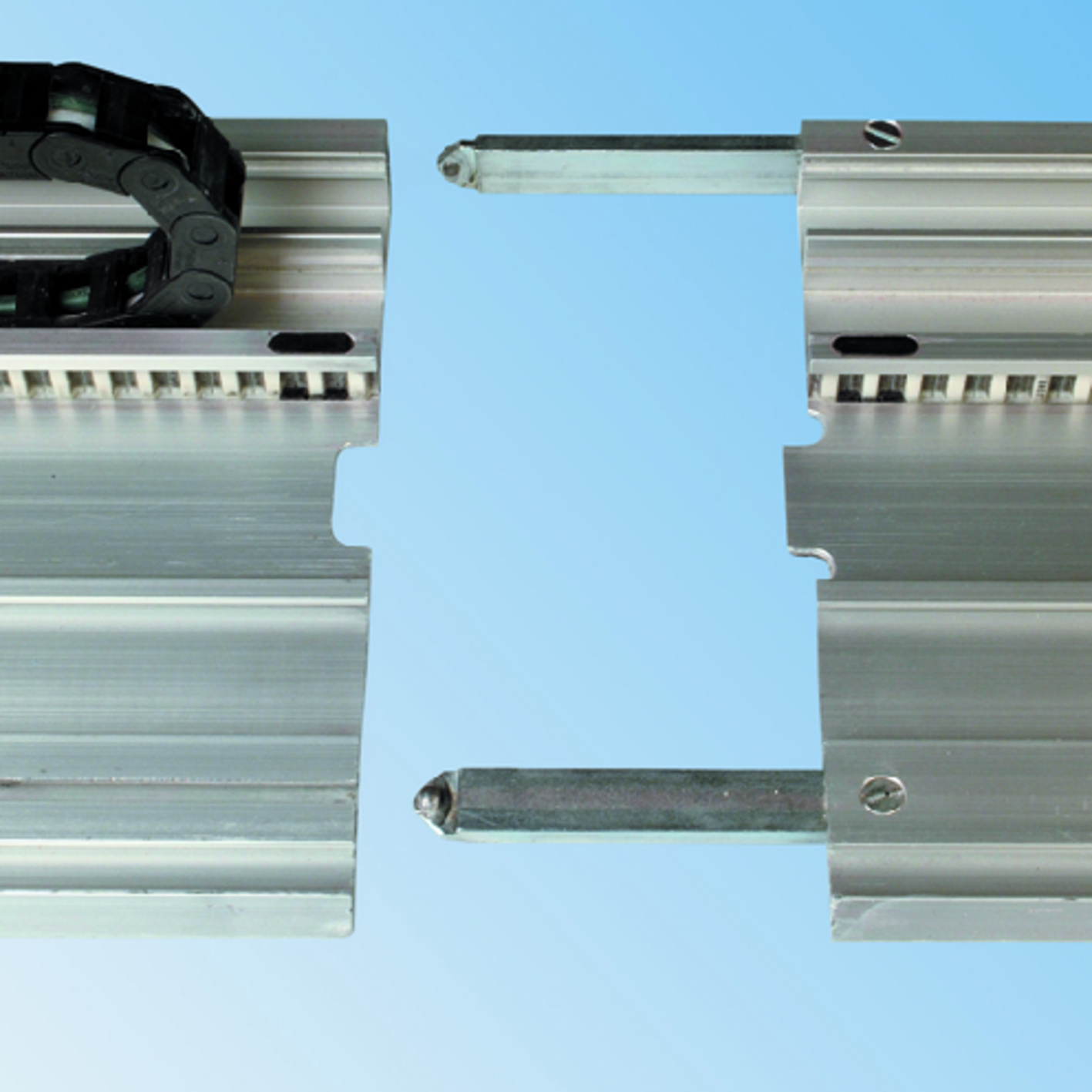

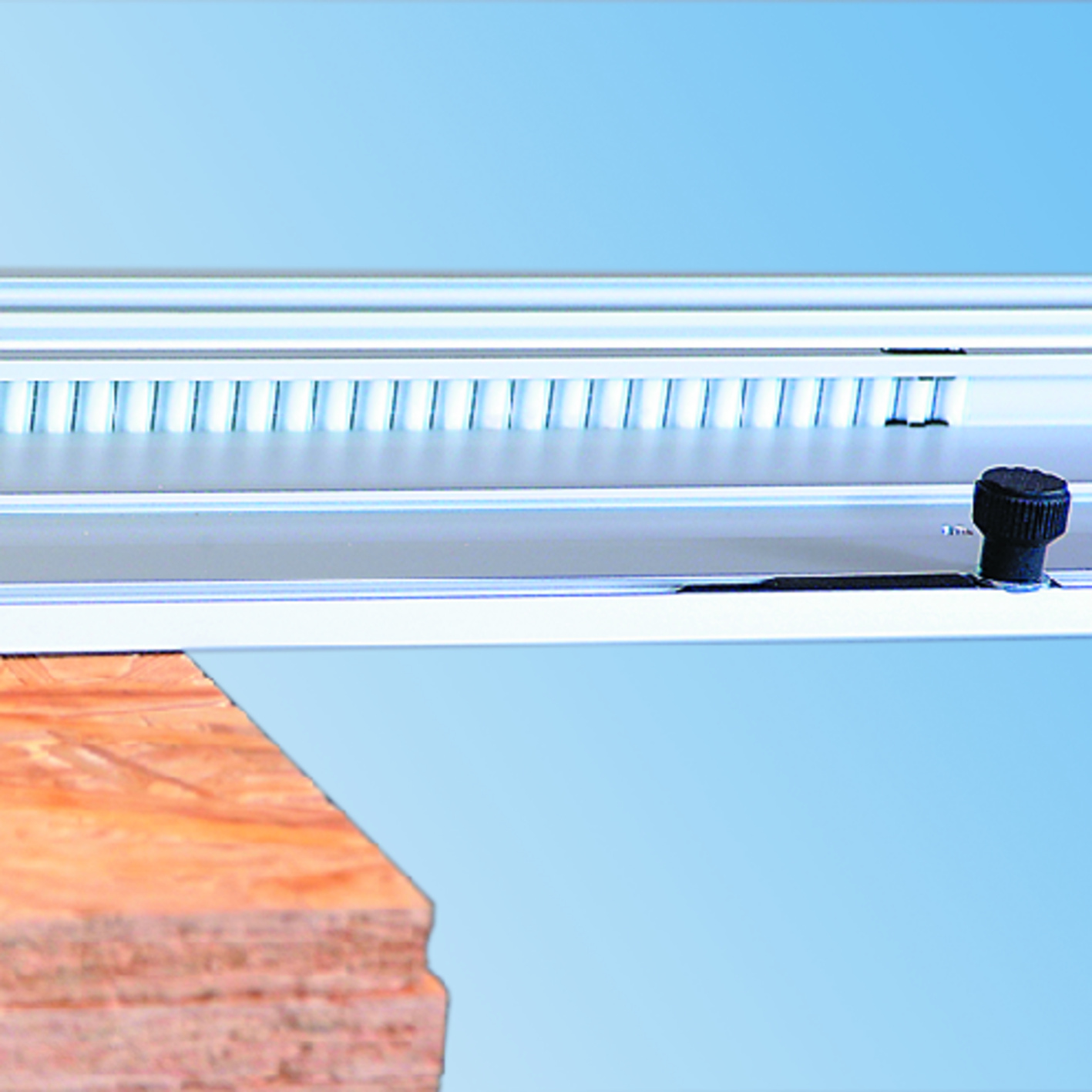

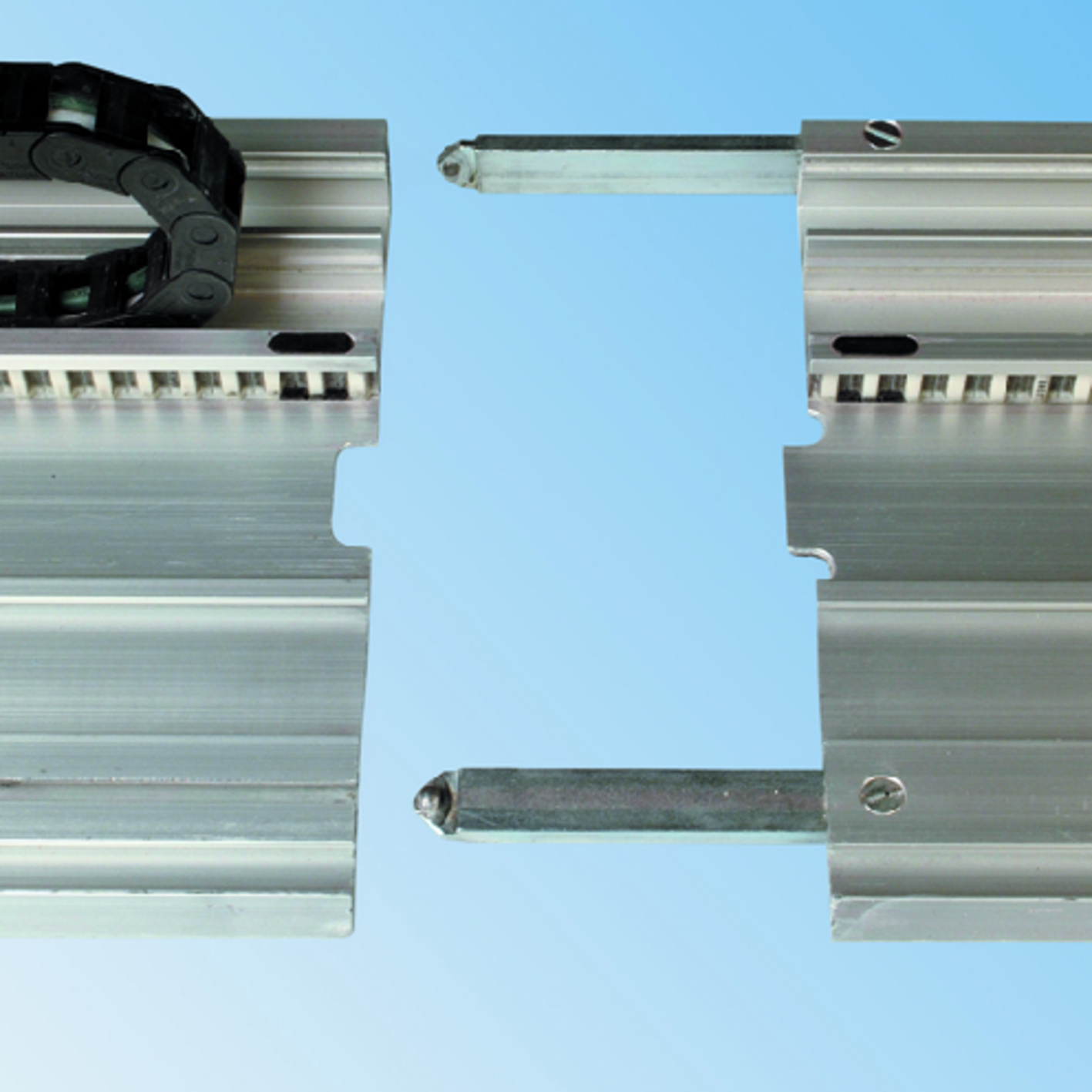

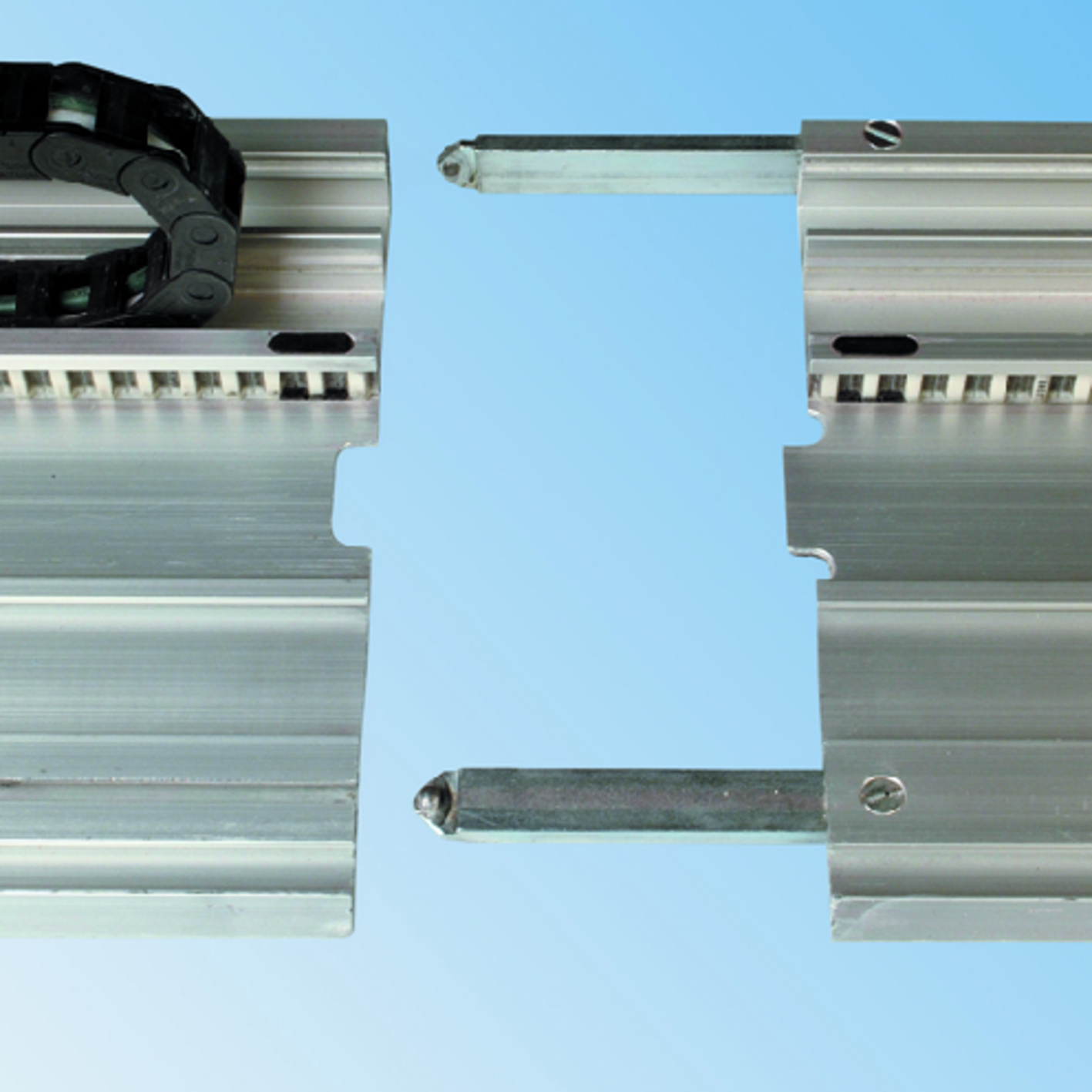

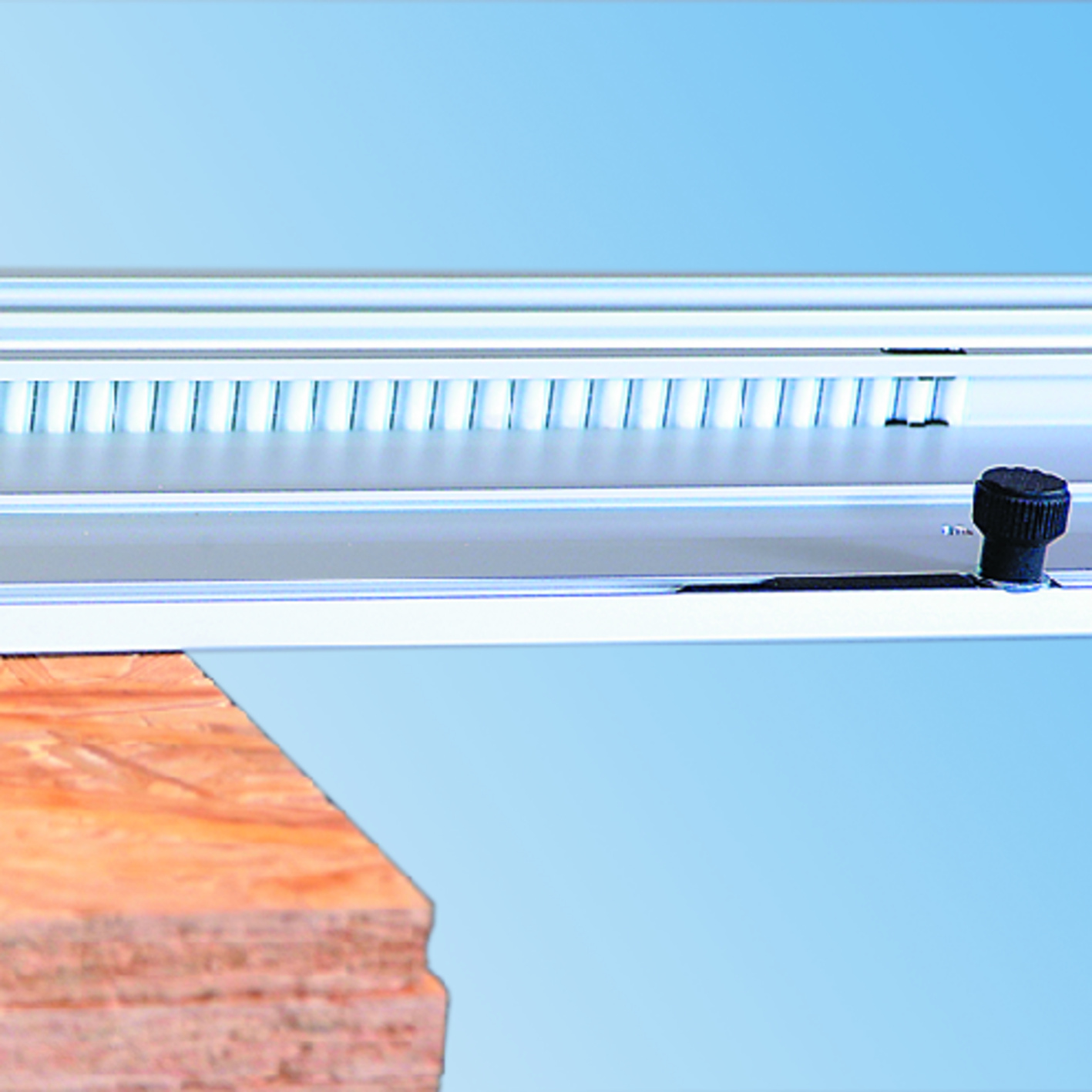

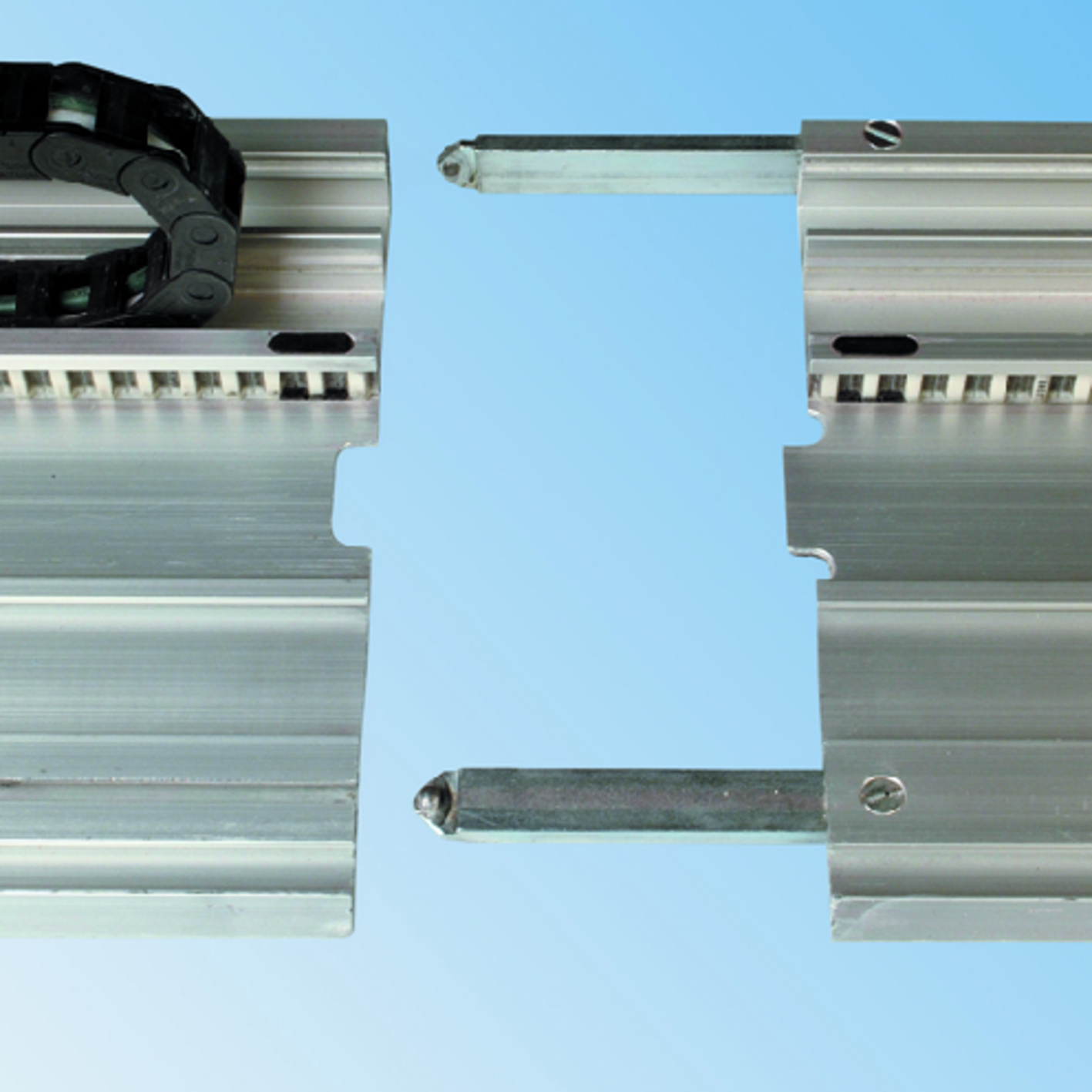

- The guide rail can be separated quickly and easily - a great aid to transportation.

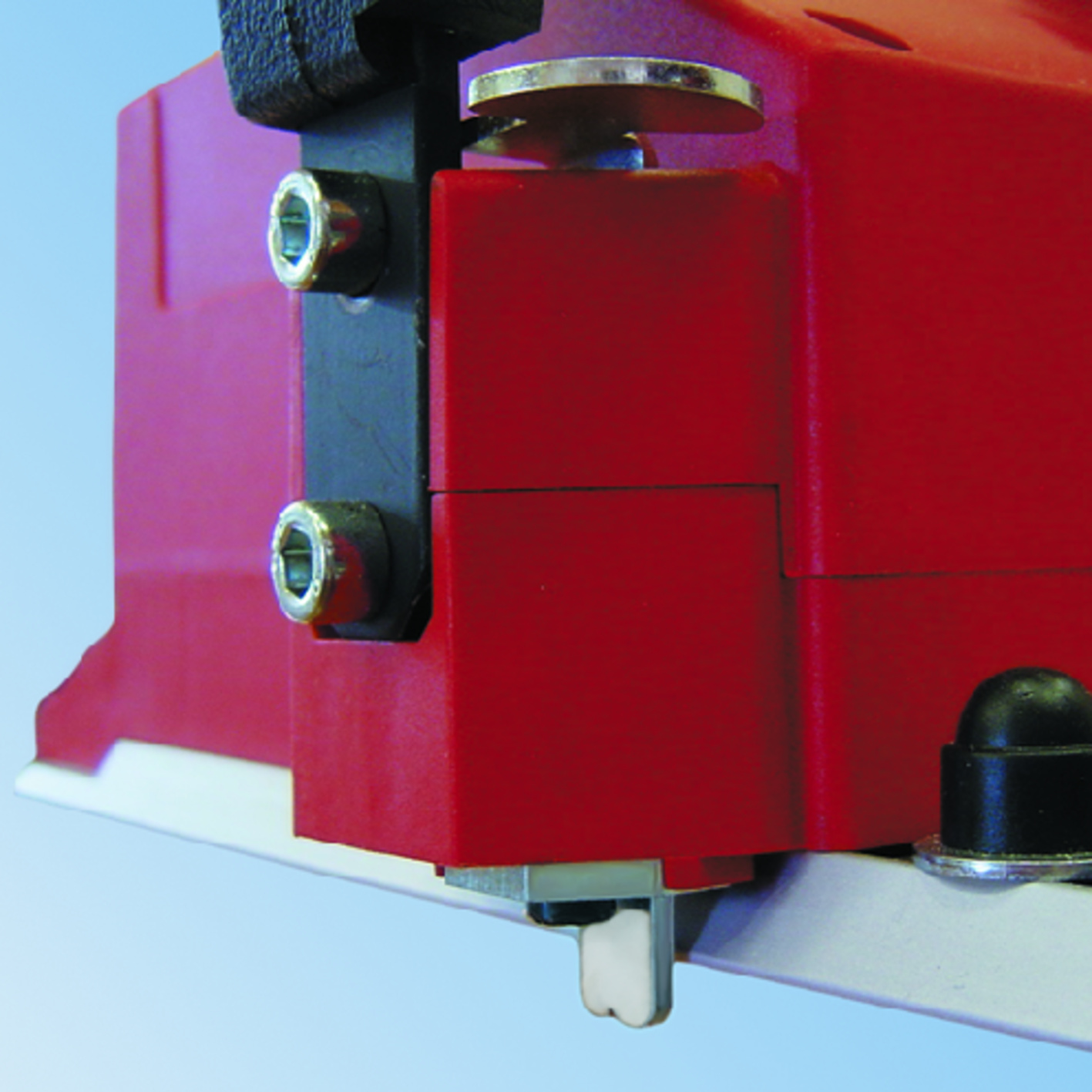

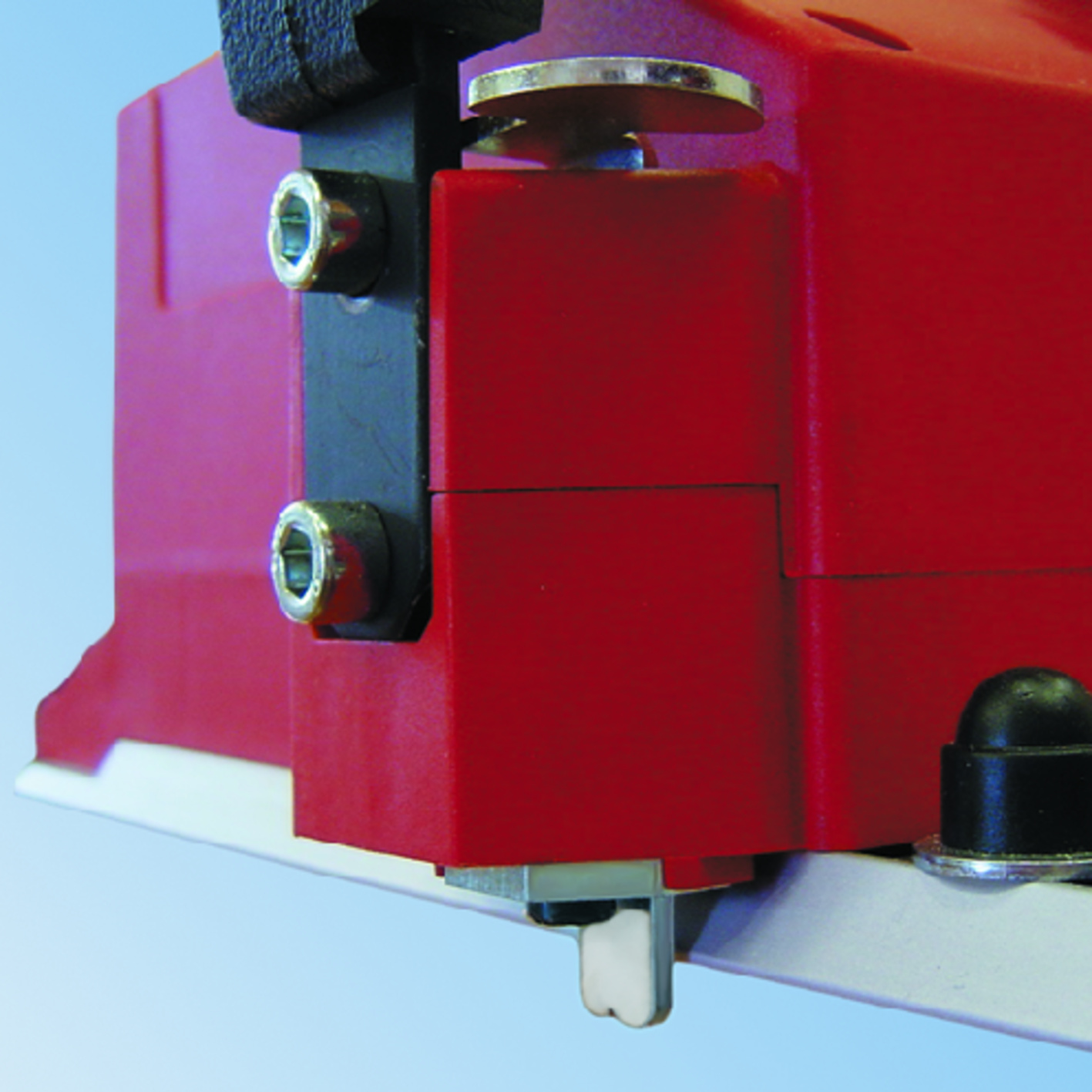

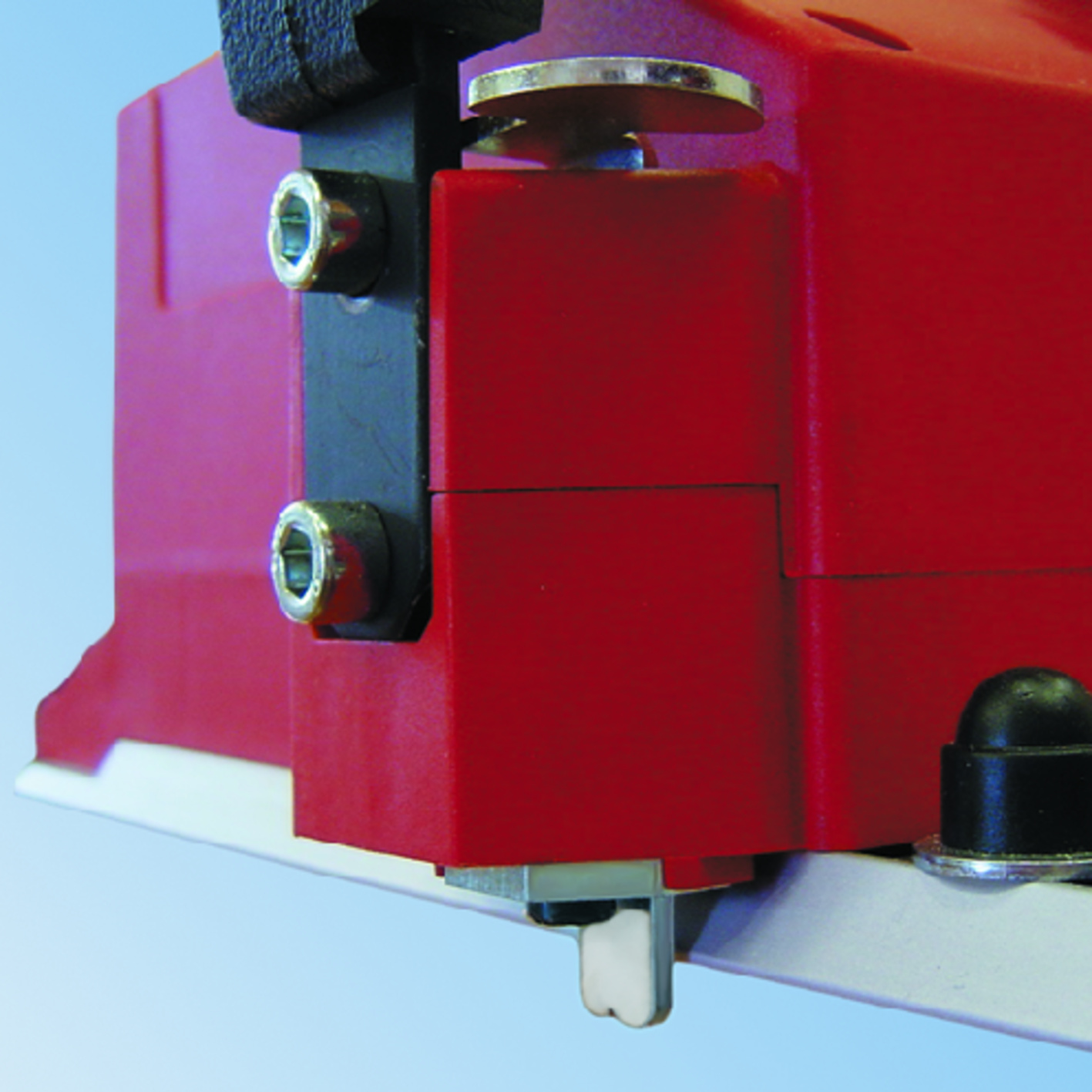

- With scoring function - for perfect tear-free cuts.

Usage

Downloads / Safety notes

Accessories / Tools

Accessories / Tools

Google Maps Consent

You don't have enabled the store locator cookies yet. To do so, click on "Open cookie configurator", enable "Store Locator" in the off canvas and click "Save".

This page requires Google Maps to work properly. Click on "Continue" to agree.