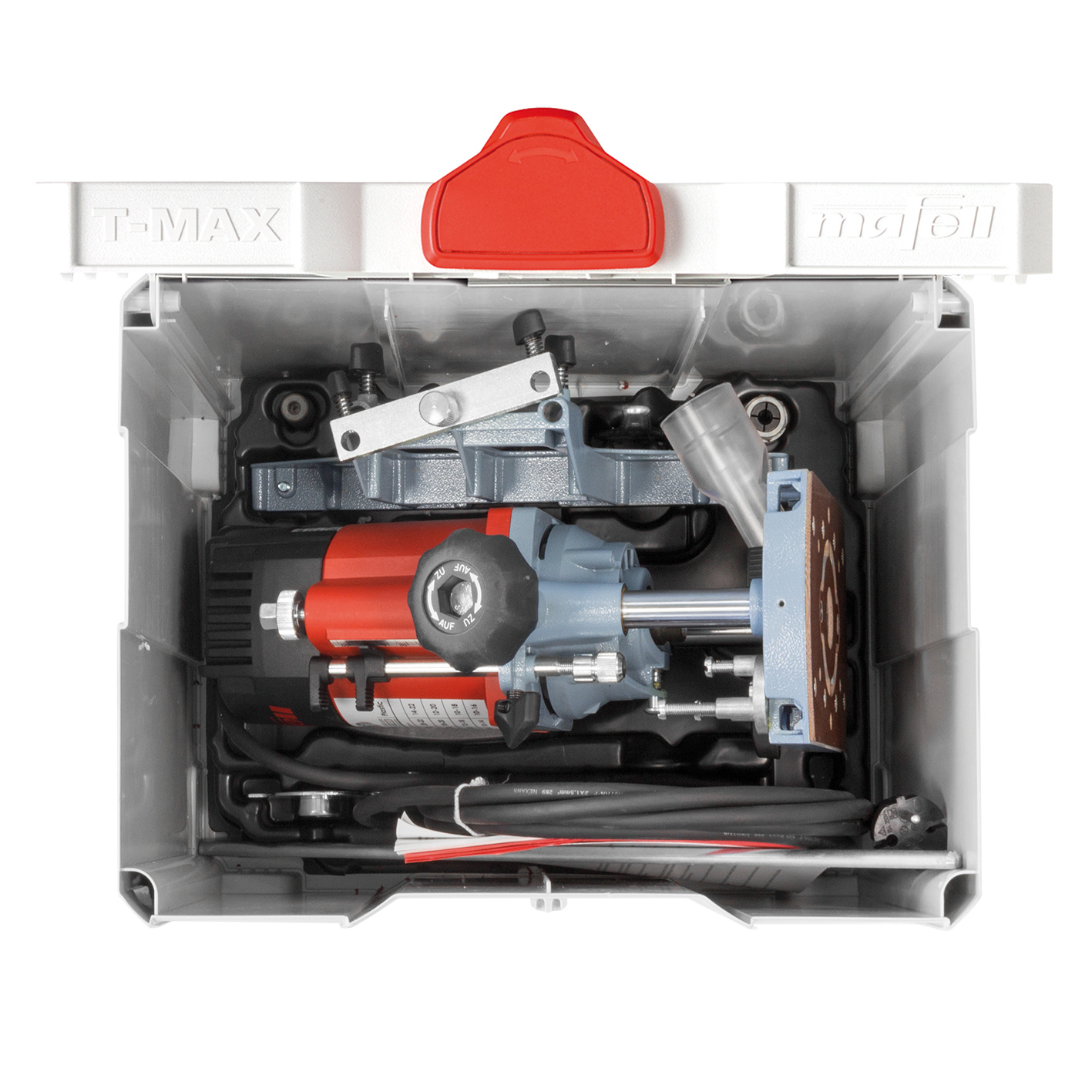

Hand Router LO 65 Ec MaxiMAX in T-MAX - GB 230 V

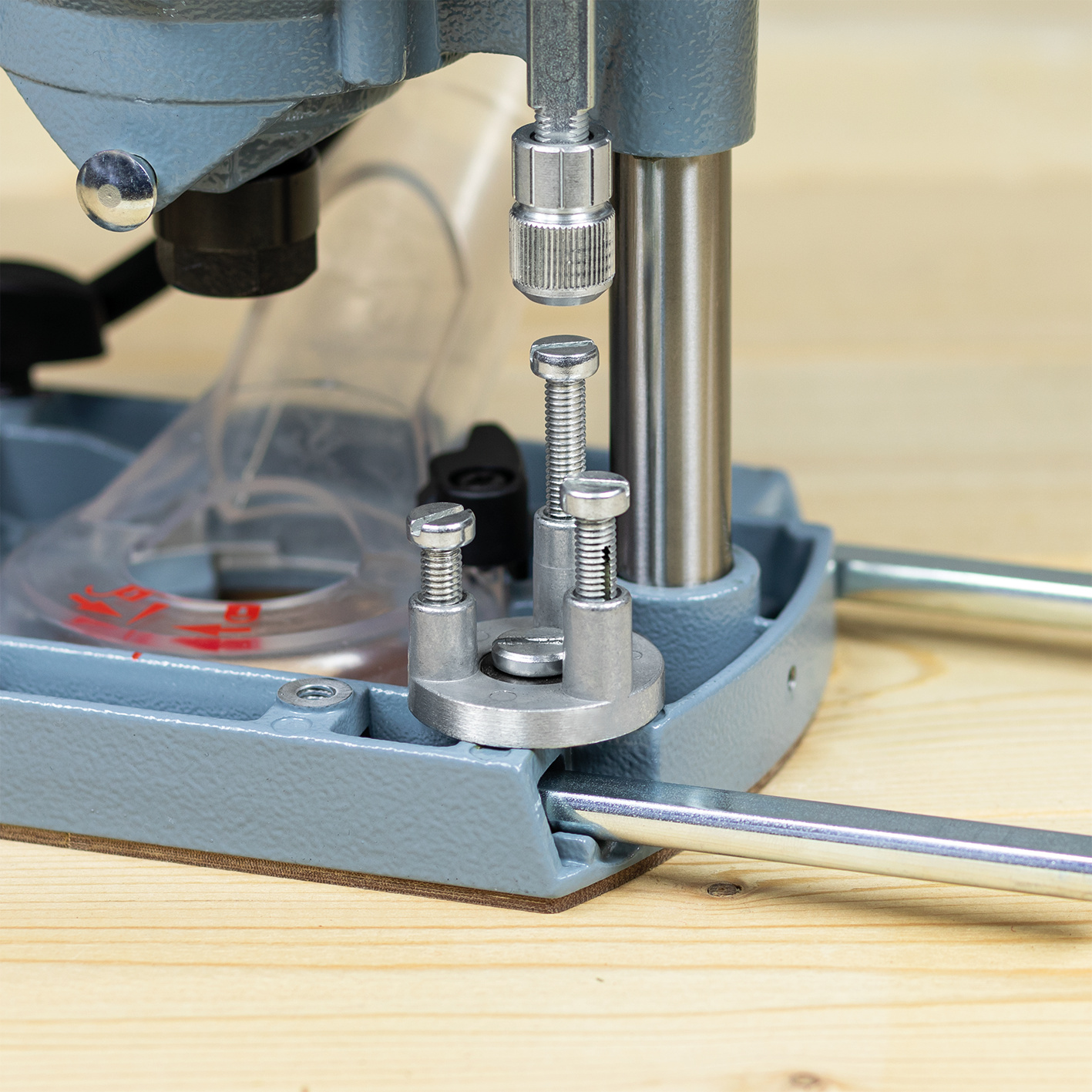

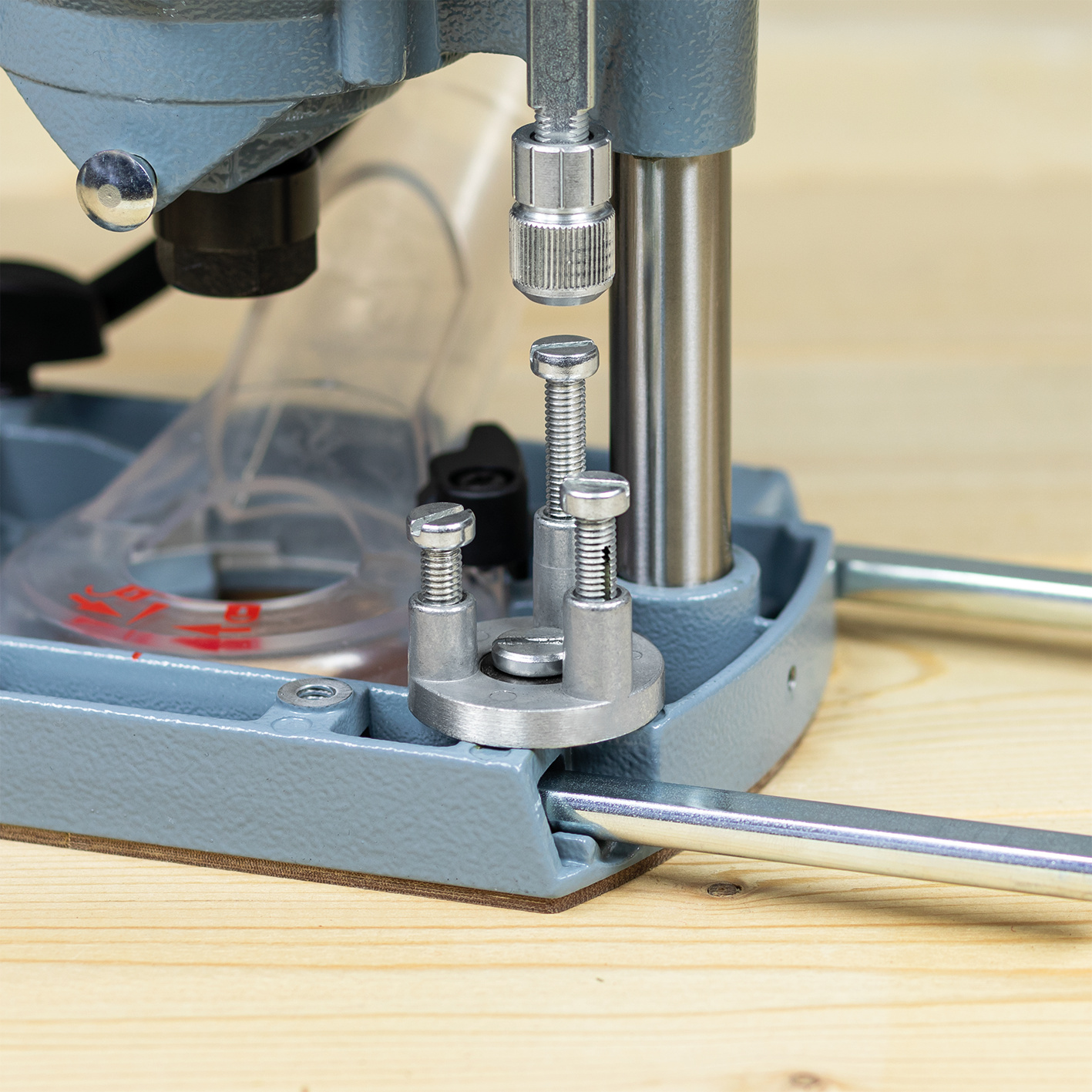

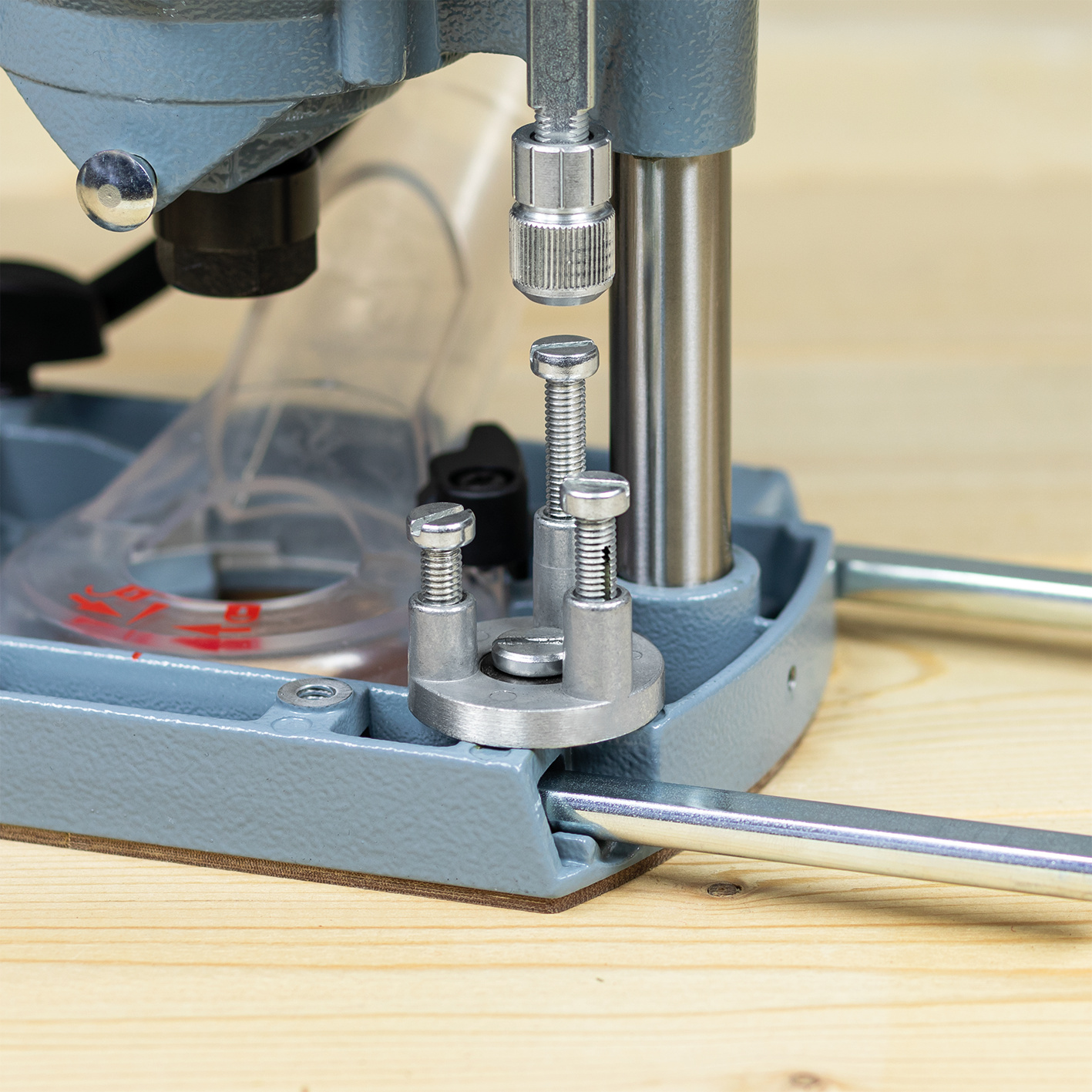

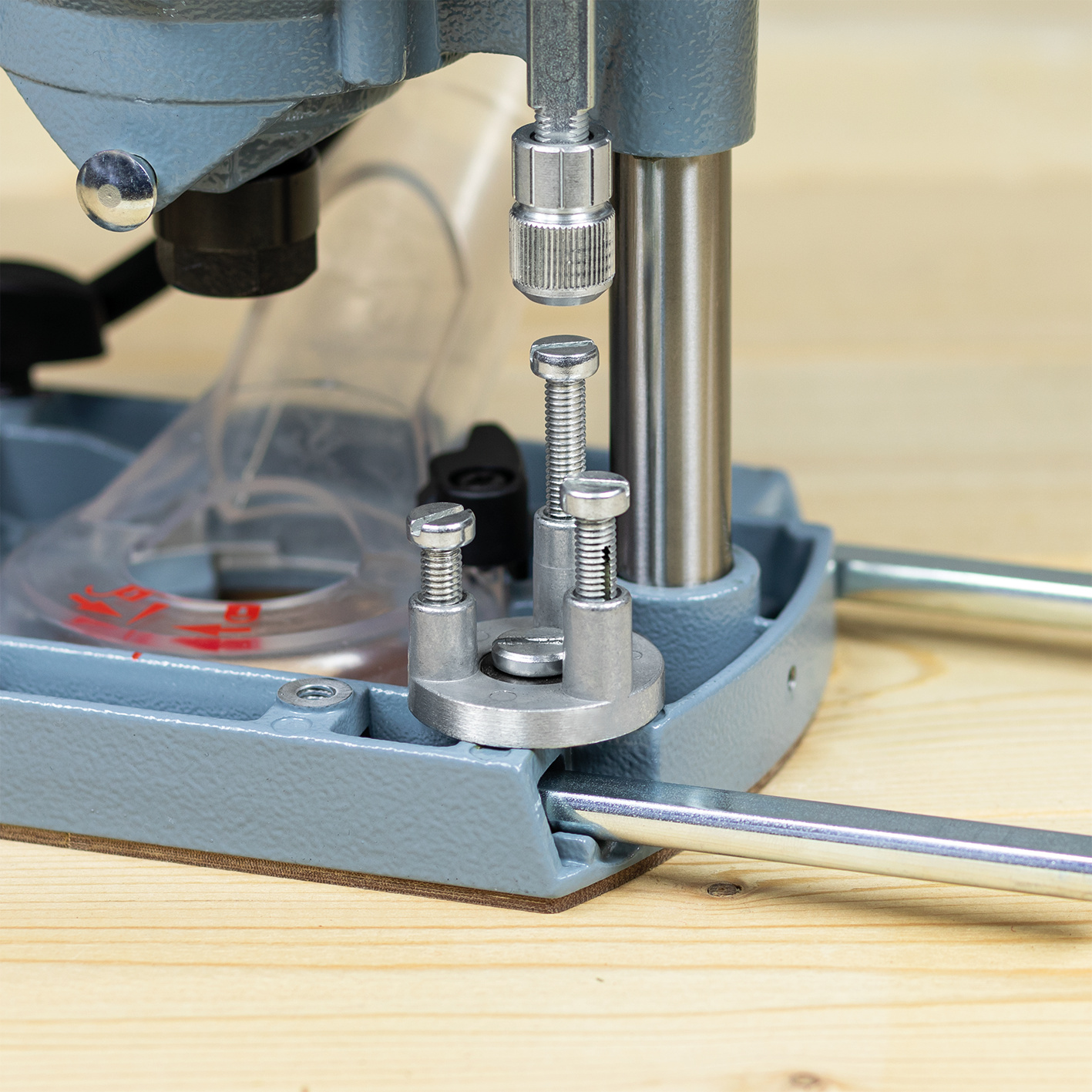

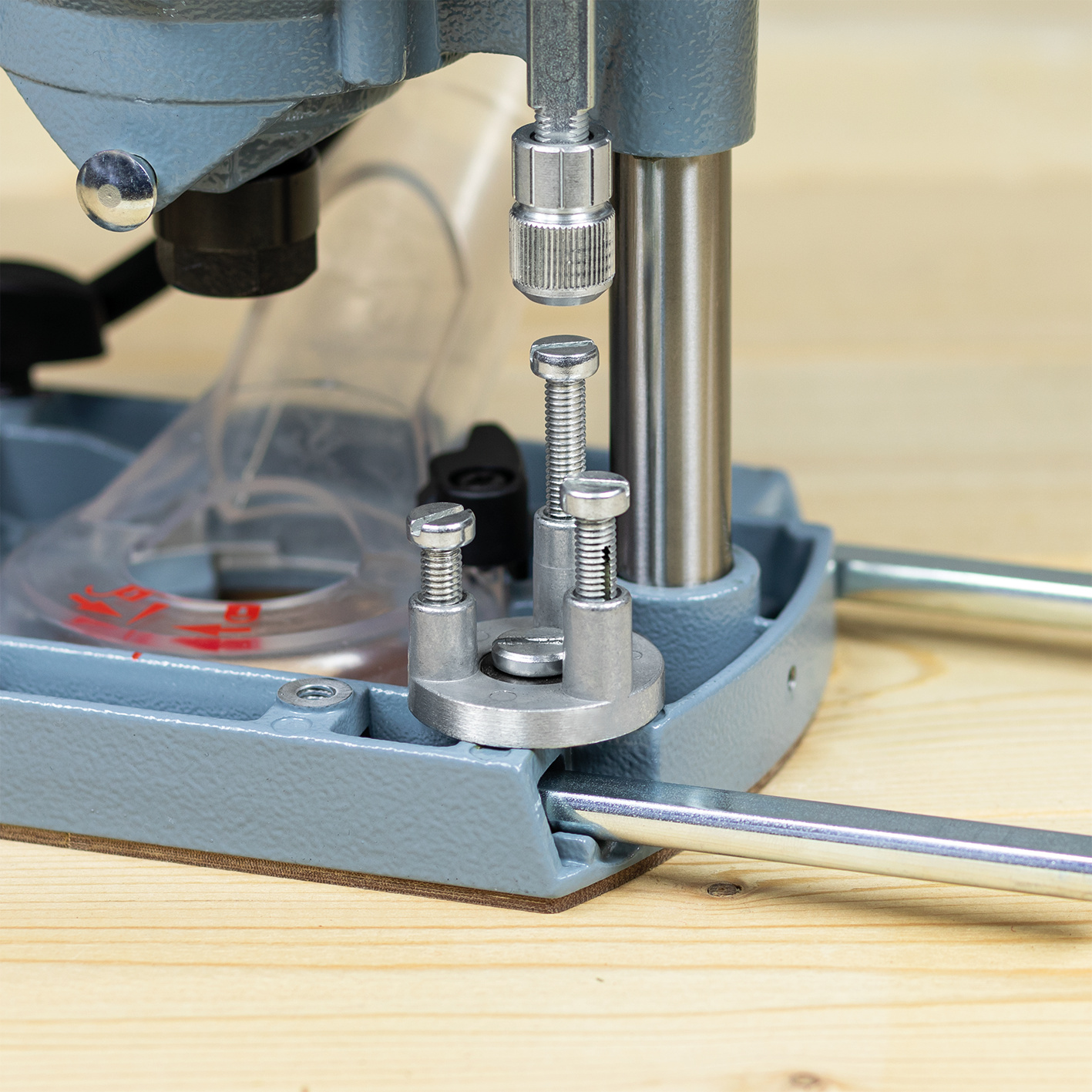

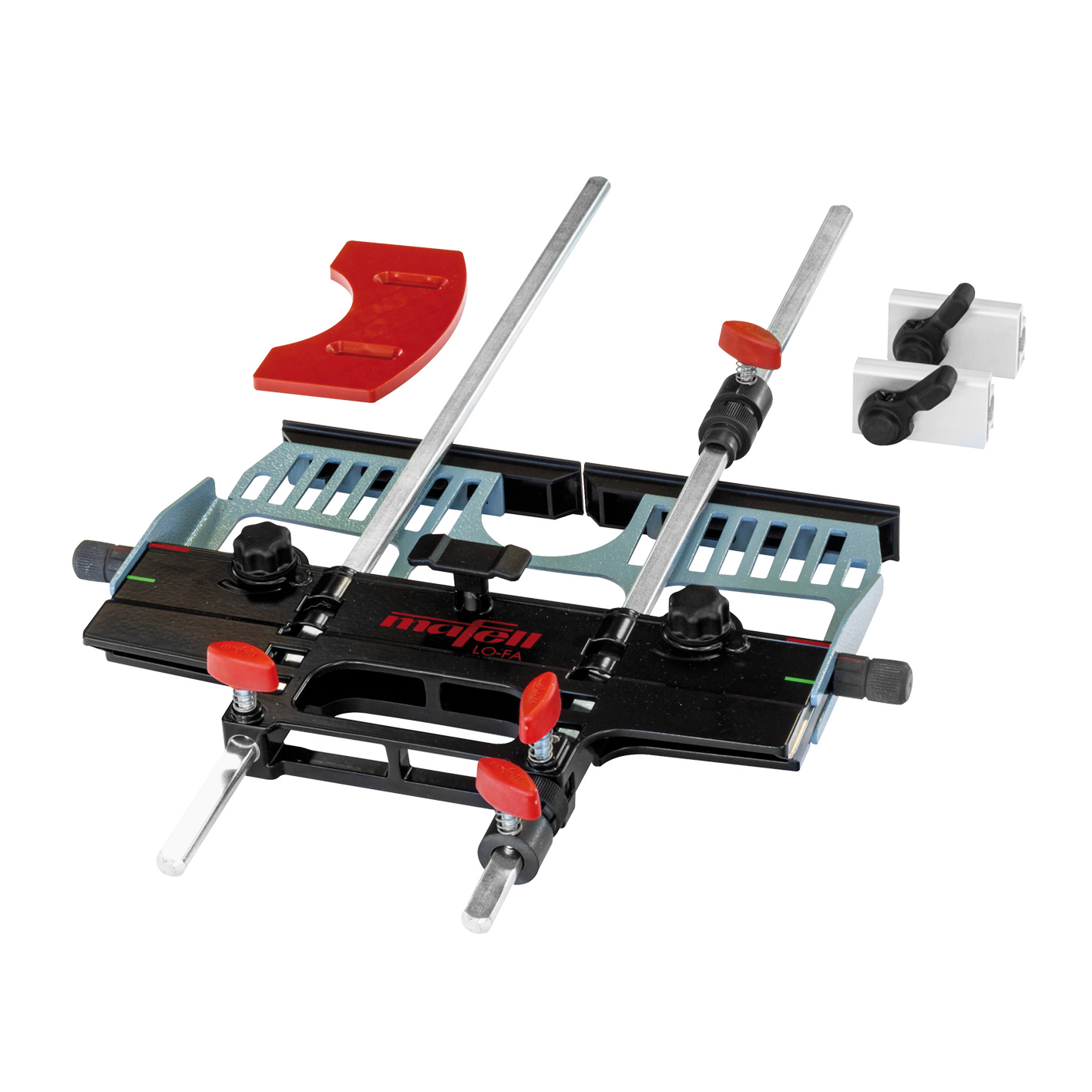

- 1 Parallel guide fence with fine adjustment

- 1 Template guide Ø 30 mm (1 3/16 in.); Ref. No. 038971

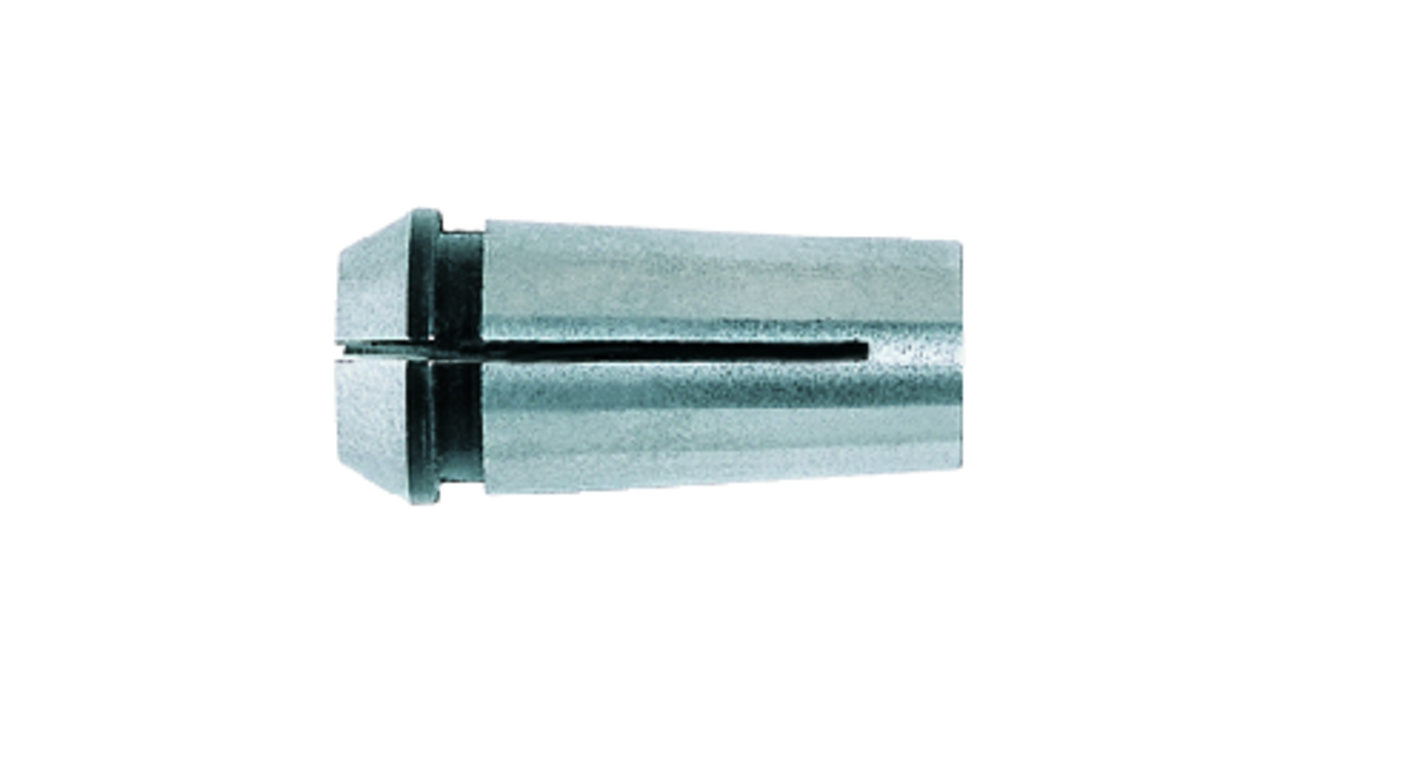

- 1 Collet Ø 8 mm; Ref. No. 093256

- 1 Adapter with internal shaft M 12 x 1; Ref. No. 201575

- 1 Chip collector; Ref. No. 204325

- 1 Revolving depth control turret

- 1 Single-end spanner 22 mm; Ref. No. 093012

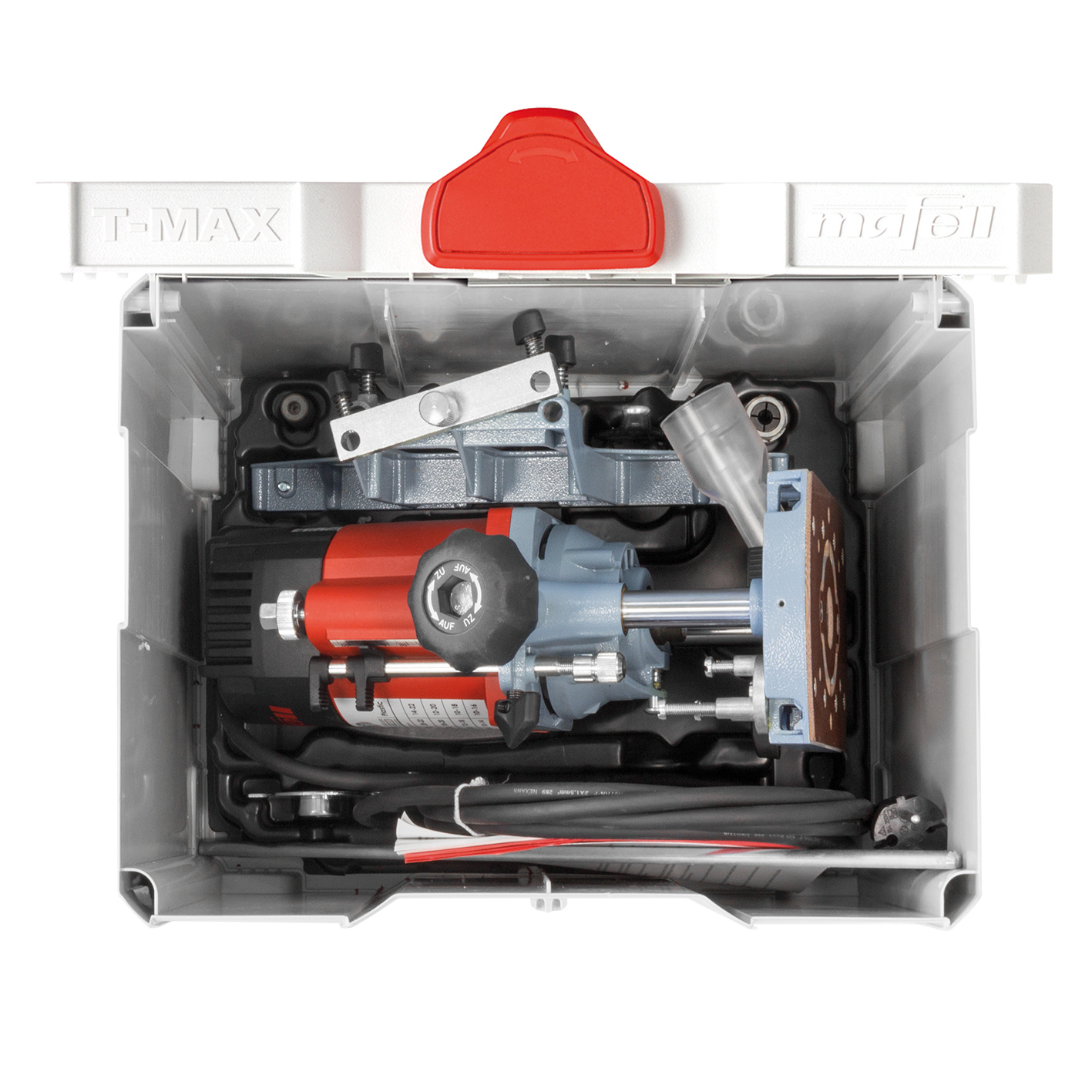

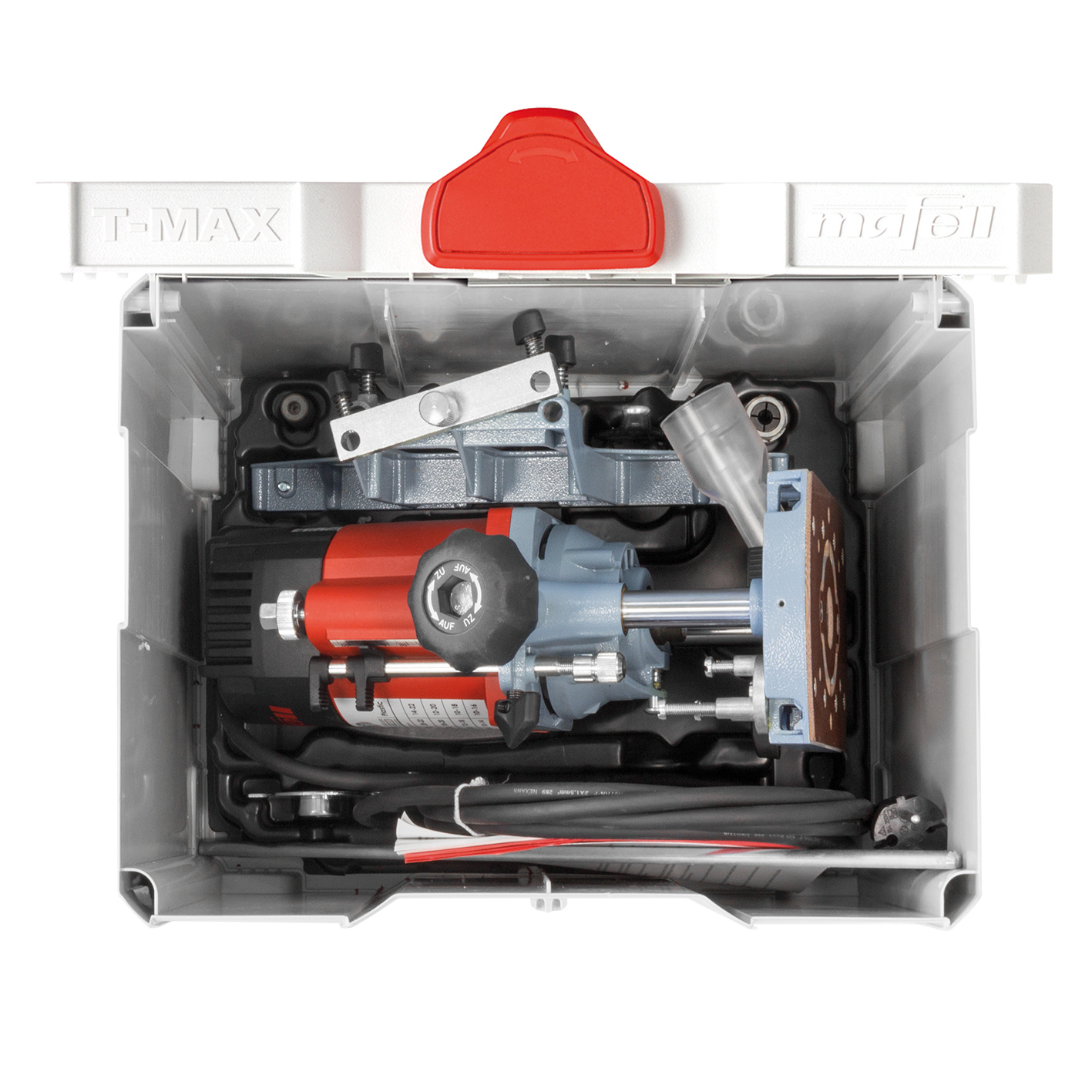

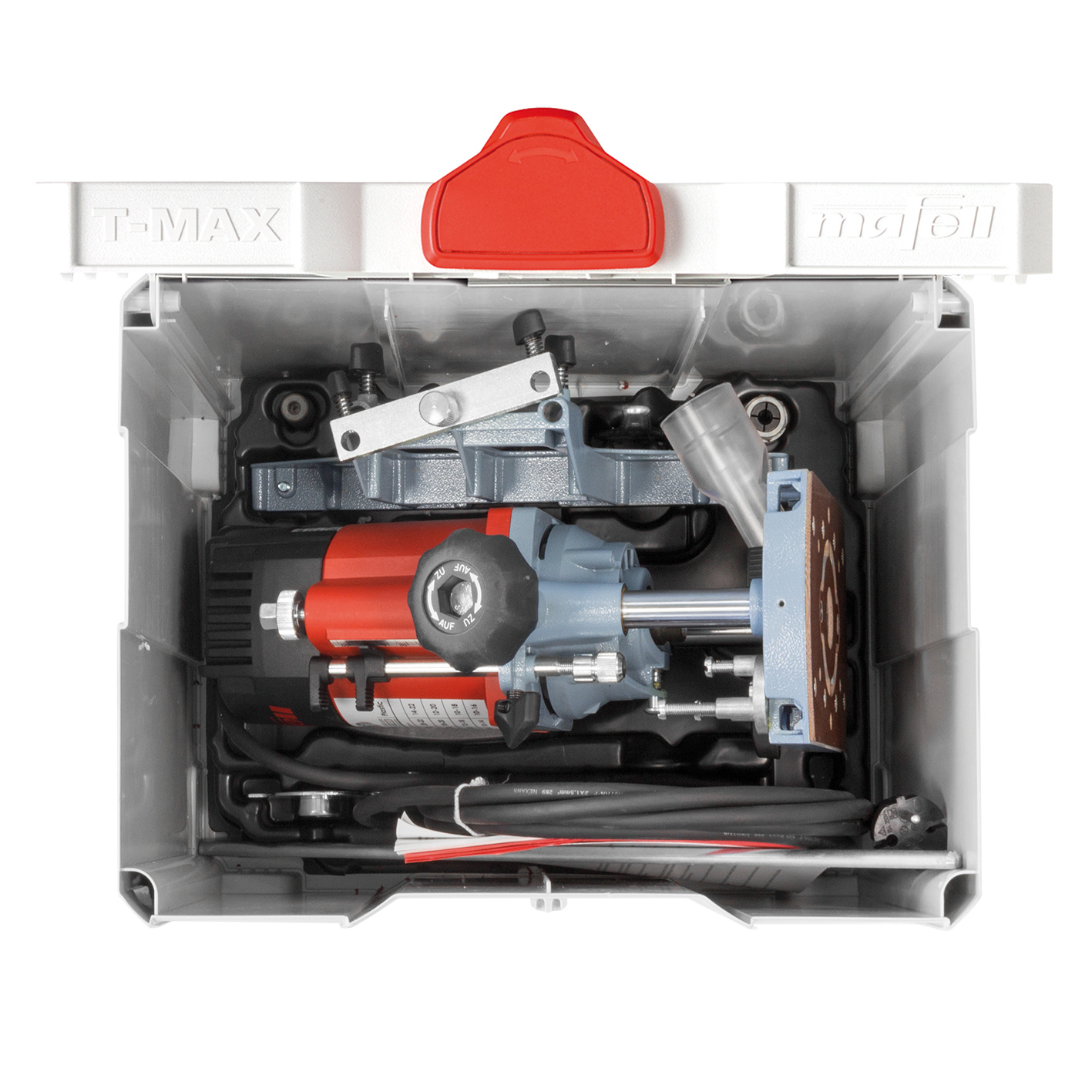

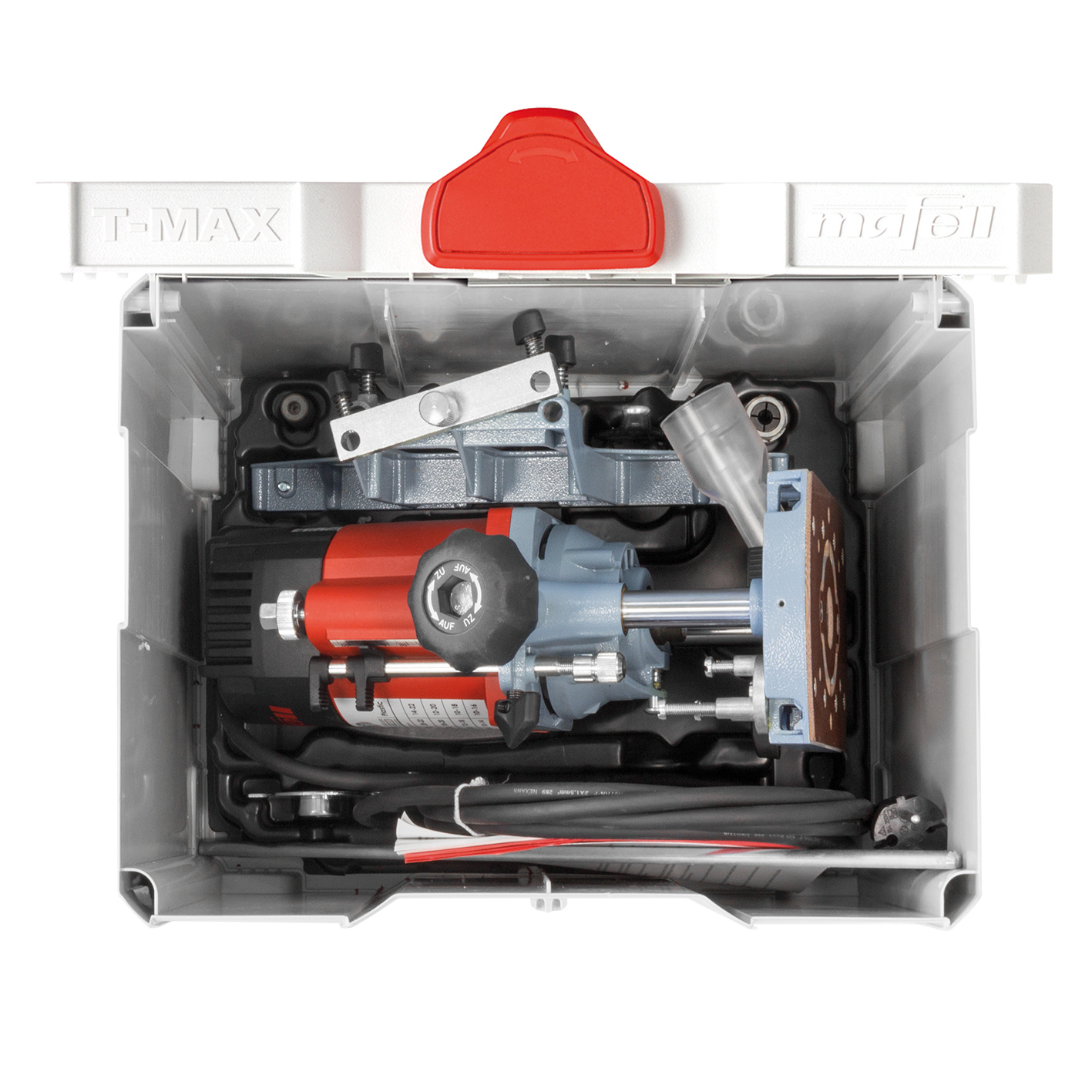

- Transport and storage box T-MAX

Technical data

| Cutting depth | 0 - 65 mm |

| Cutting depth | 0 - 2 9/16 in |

| Chuck Ø | 1/2" / 6 - 12 mm |

| Nominal No. of strokes – no load | 10000 - 22000 1/min |

| Nominal power input | 2600 W |

| Nominal power input | 3.5 hp |

| Weight | 6,9 kg |

| Weight | 15.2 lbs |

| Universal motor | 230 V / 50 Hz |

Product details

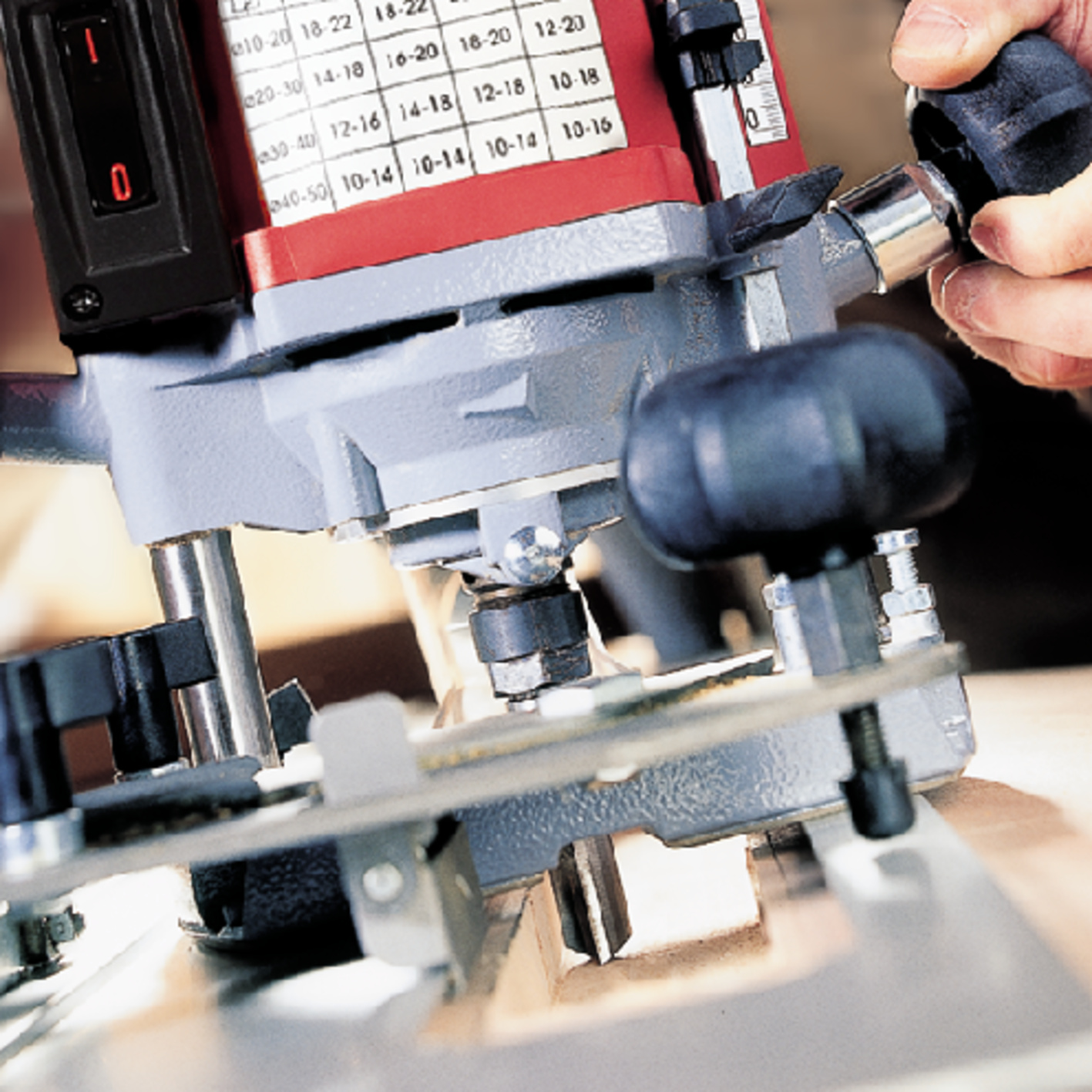

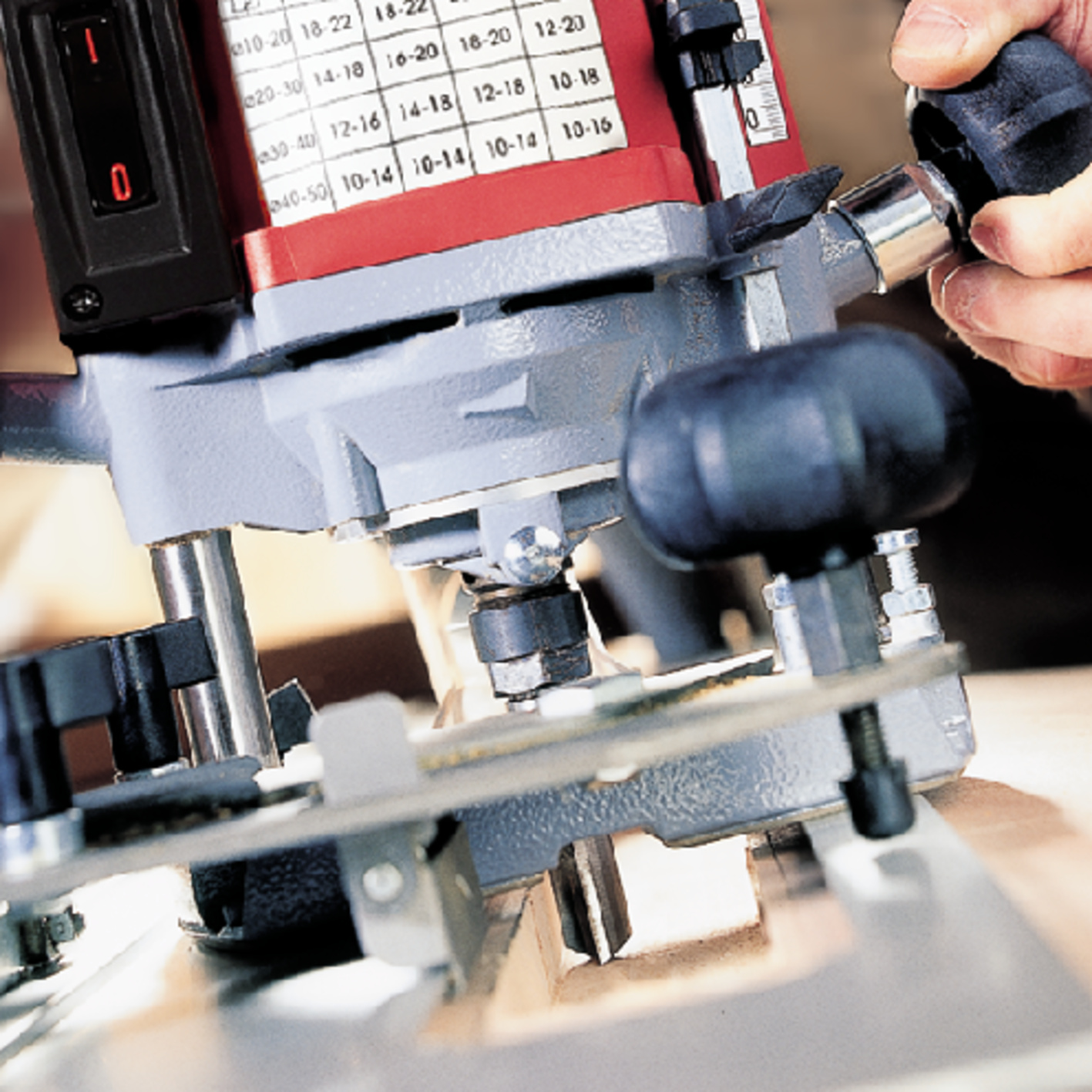

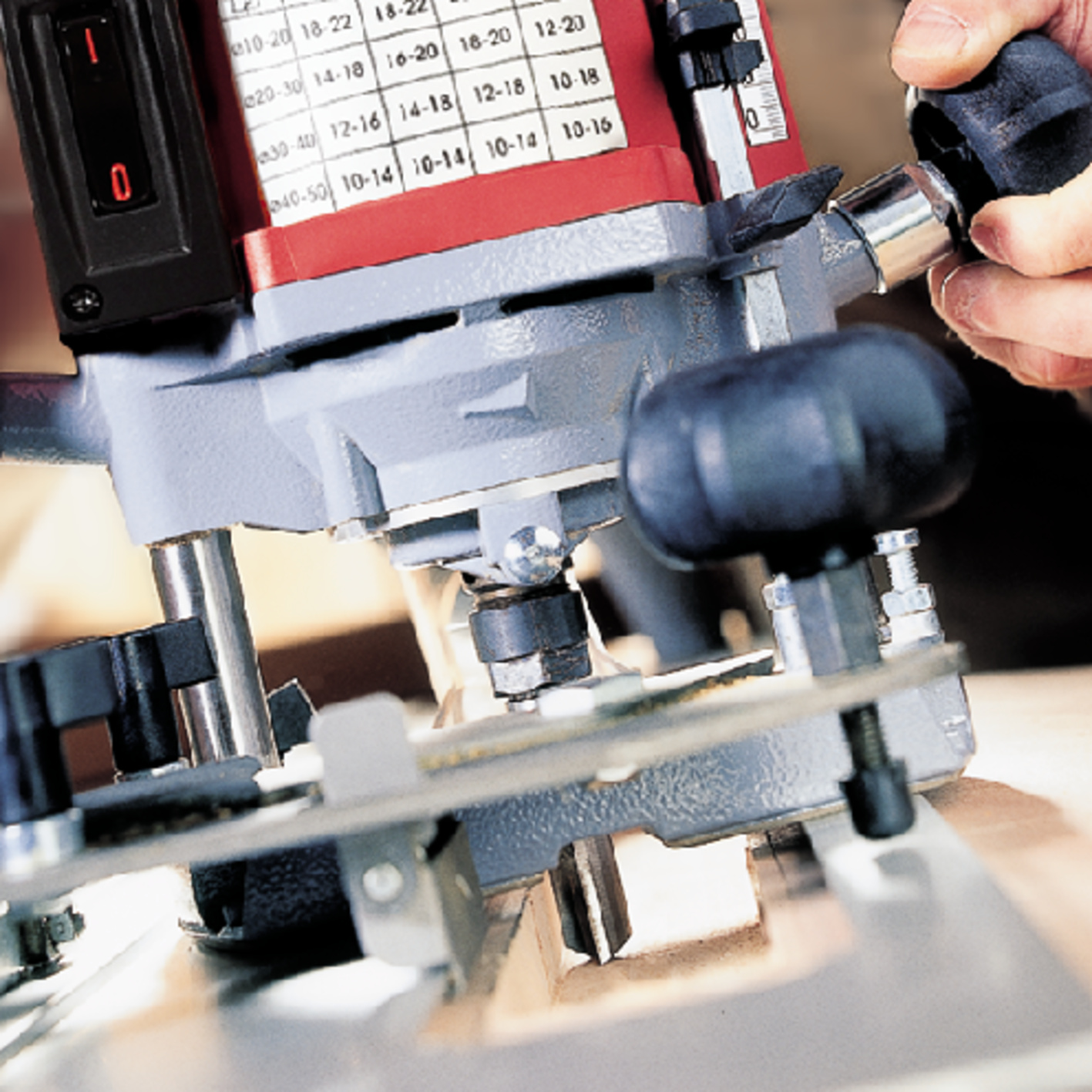

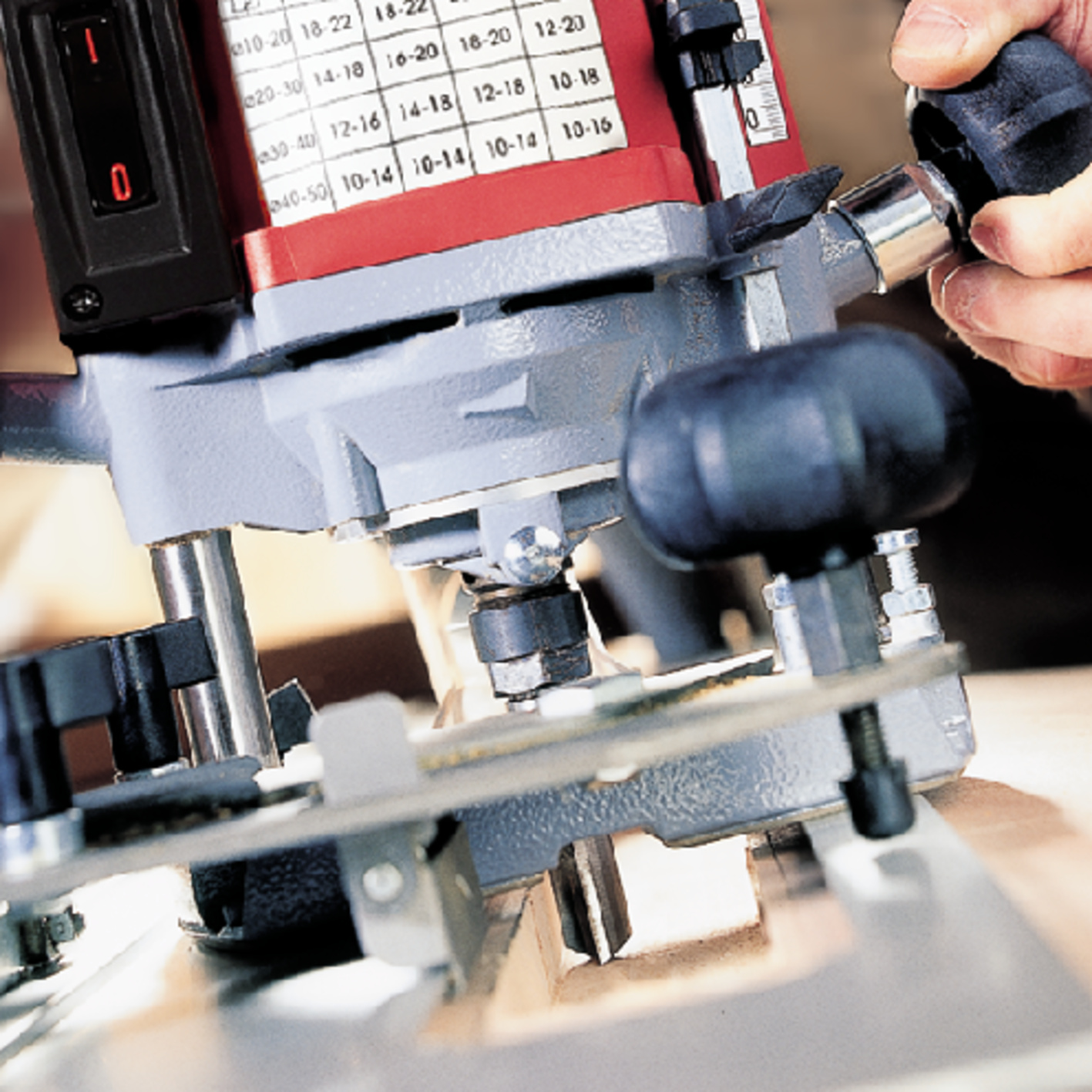

Sheer power and high torque take on a whole new meaning with the high-output CUprex motor. It offers performance-optimized digital electronics and newly developed control technology. Its speed is continuously variable according to the nature of the material and application.

The coordinated, optimised components enable the machine to be used for filigree work requiring absolute precision. The fine adjustment of the cutting depth can be fixed exactly, making refinishing an exception.

The groove in the base plate permits flush trimming of edge bands without any additional attachments.

To replace the cutter quickly and easily, simply turn the LO 65 Ec upside down. A standard spindle locking mechanism is fitted as a matter of course.

Applications

- Profiling and cutting grooves

- Cutting for fittings/hardware

- Dovetail joints (Lignatool, Arunda)

- For routing stair housings

- Compatible materials include solid wood and board materials

Advantages

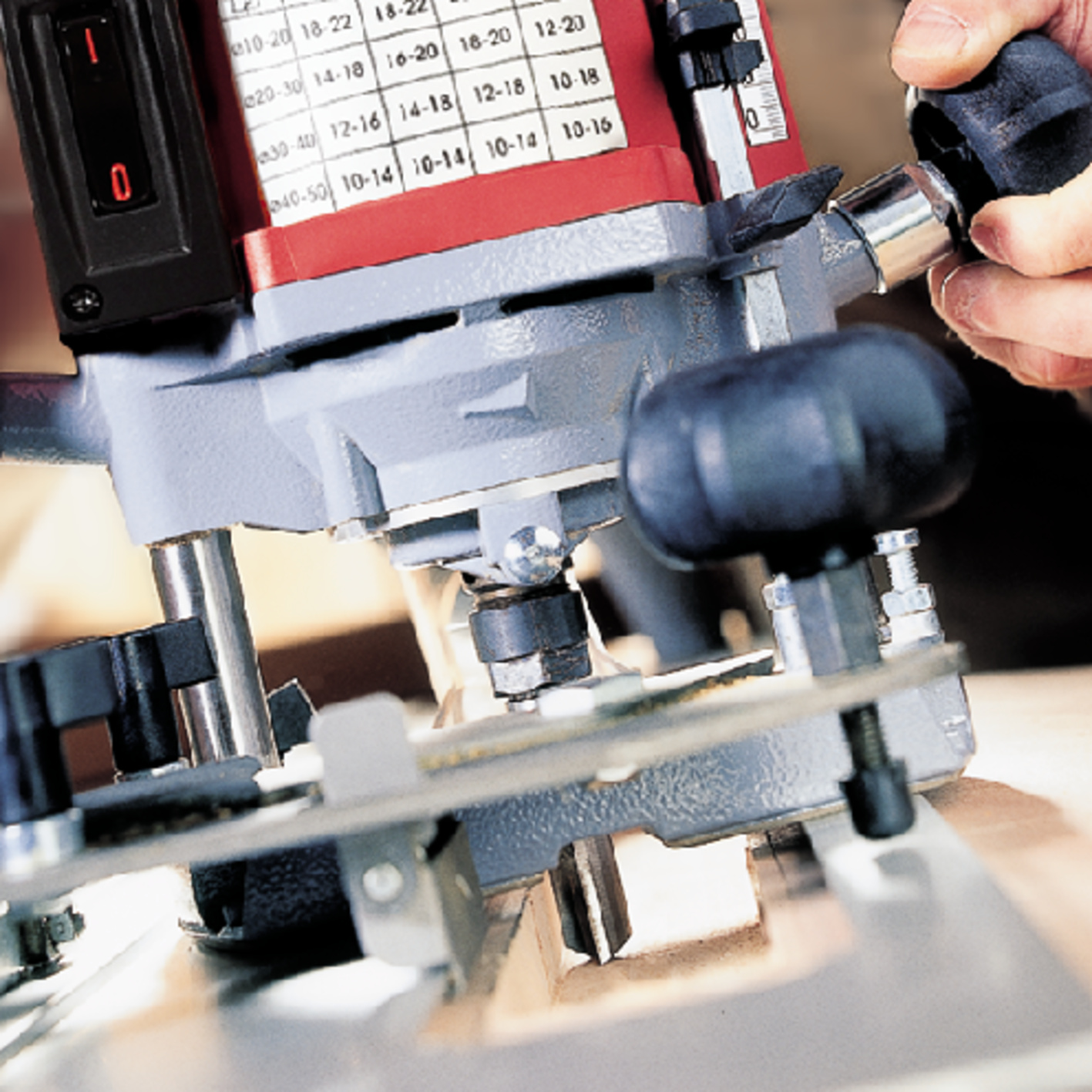

- Twin-guide parallel fence with fine adjustment – for precise guidance.

- Individual setting of speed, cutting depth and guide – for a wide variety of applications.

- Considerable time-saving – due to fast cutting with the CUprex high-powered 2600 watt (3.0 hp) motor.

- With voltage loss switch for protection against uncontrolled reconnection after a power interruption.

Usage

Downloads / Safety notes

Accessories / Tools

Accessories / Tools

Google Maps Consent

You don't have enabled the store locator cookies yet. To do so, click on "Open cookie configurator", enable "Store Locator" in the off canvas and click "Save".

This page requires Google Maps to work properly. Click on "Continue" to agree.