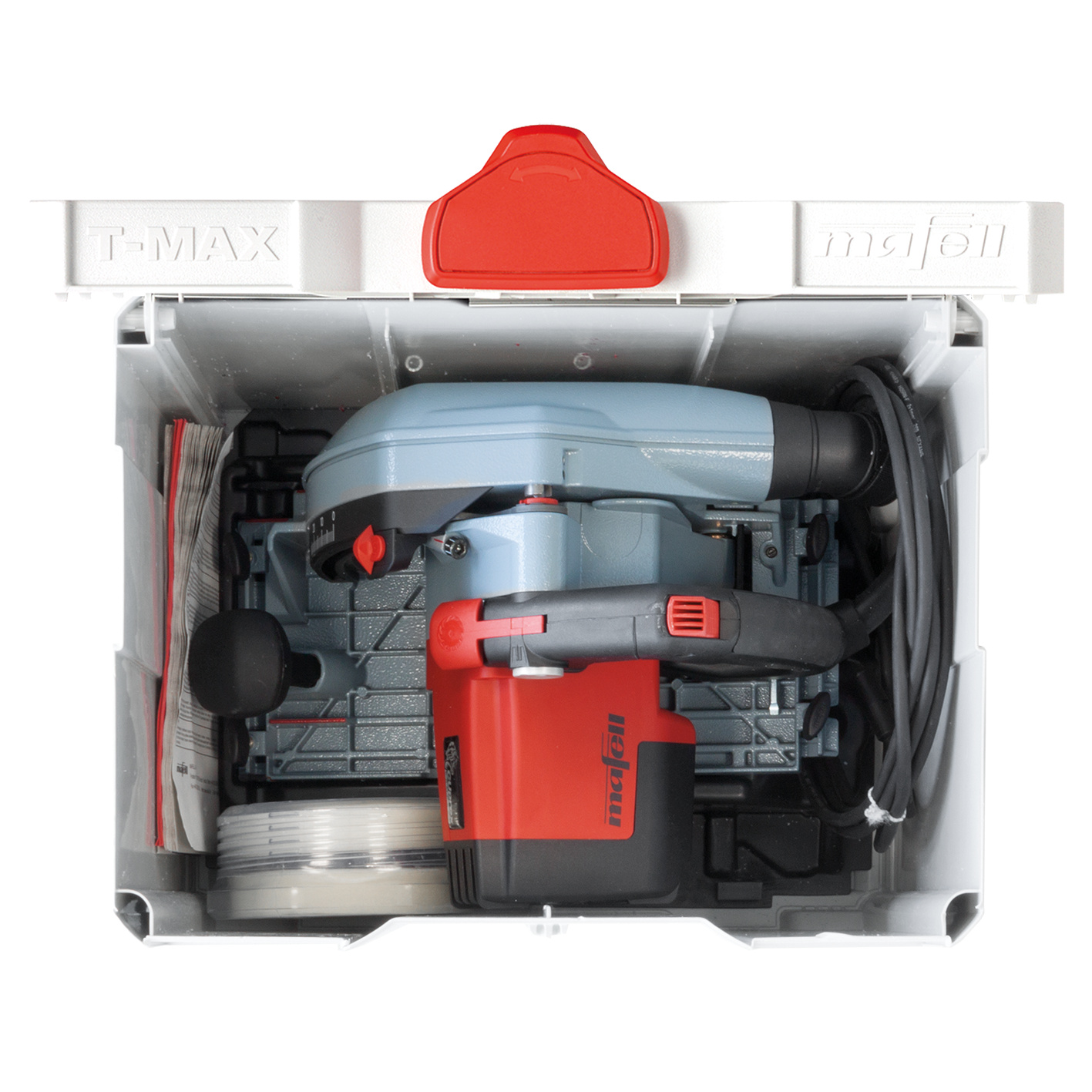

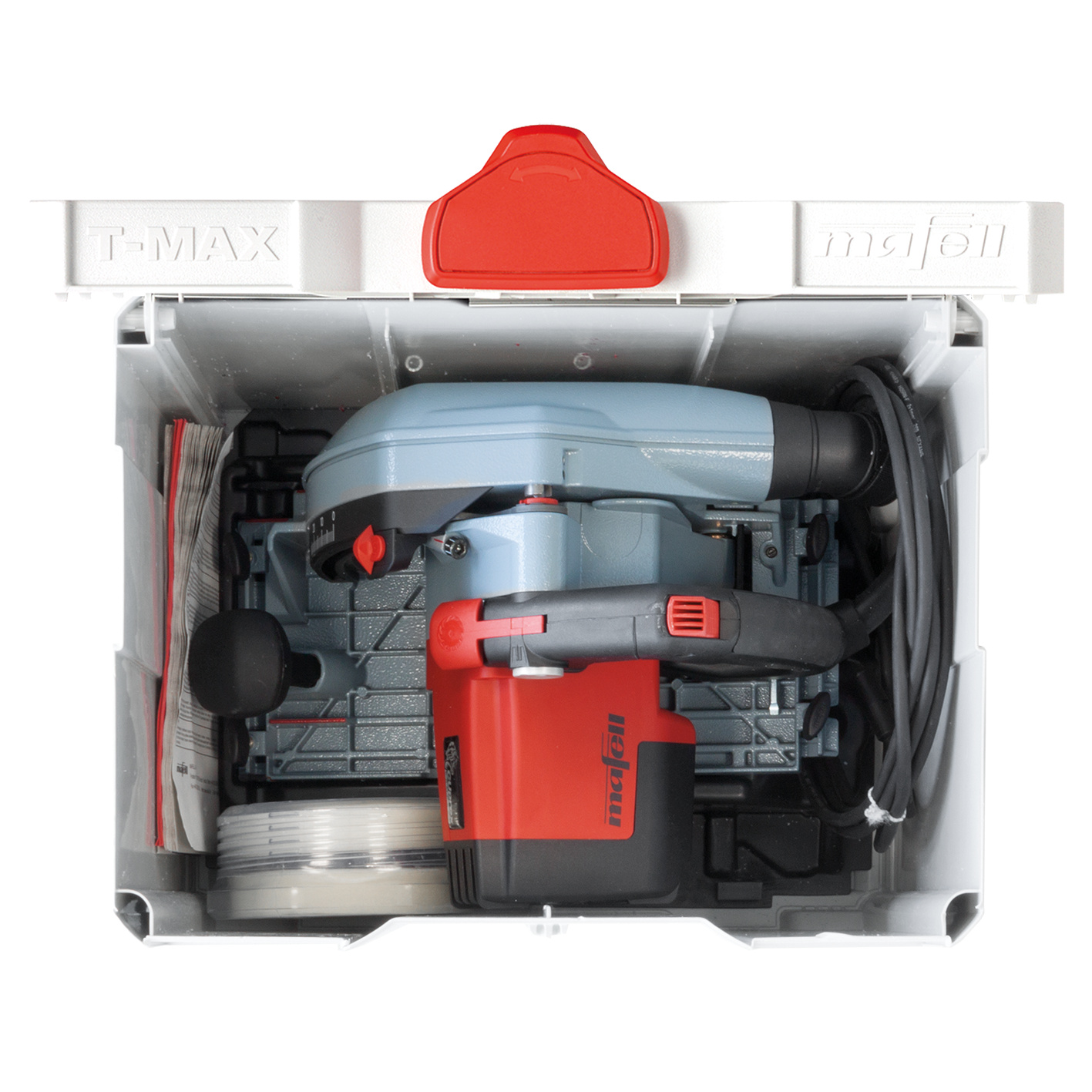

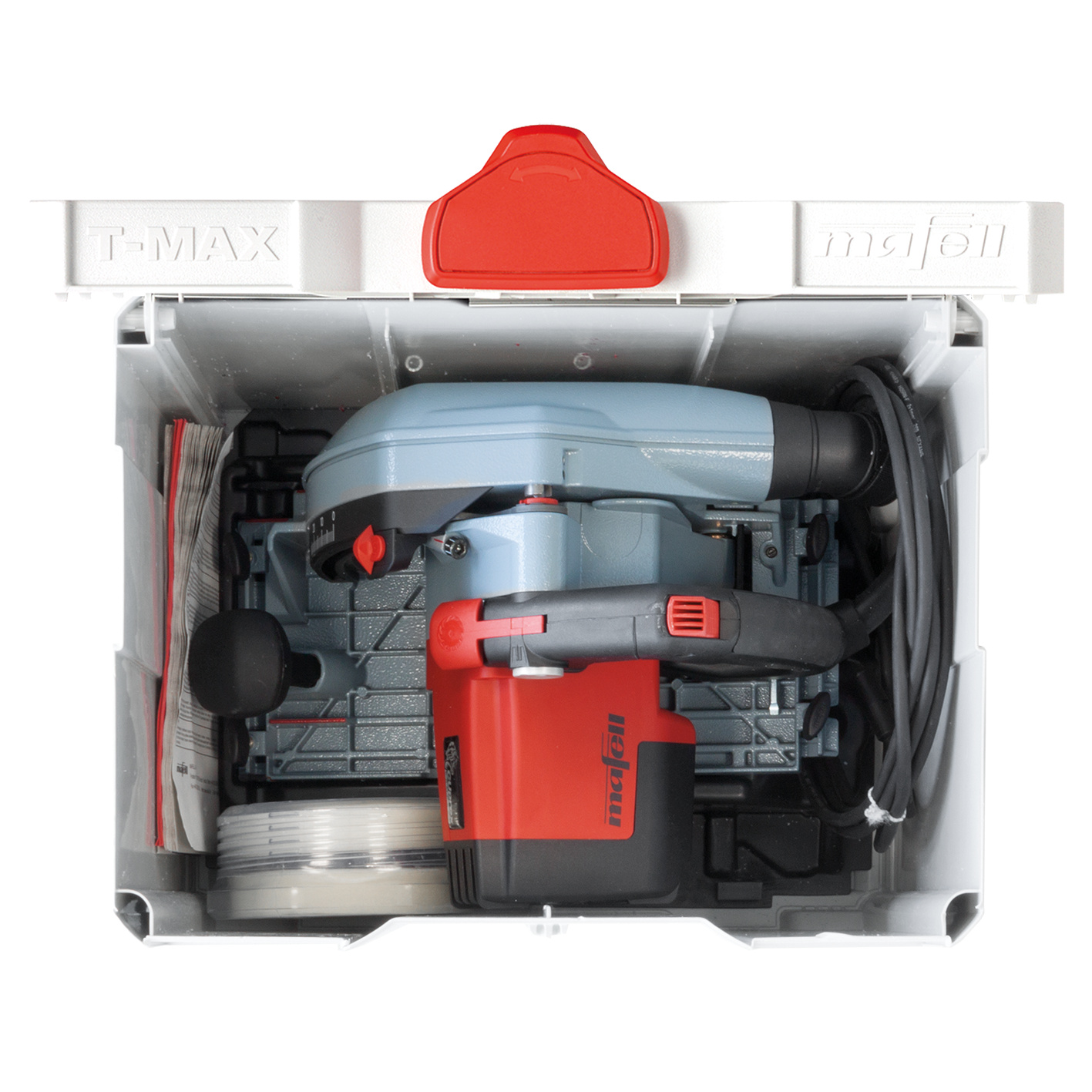

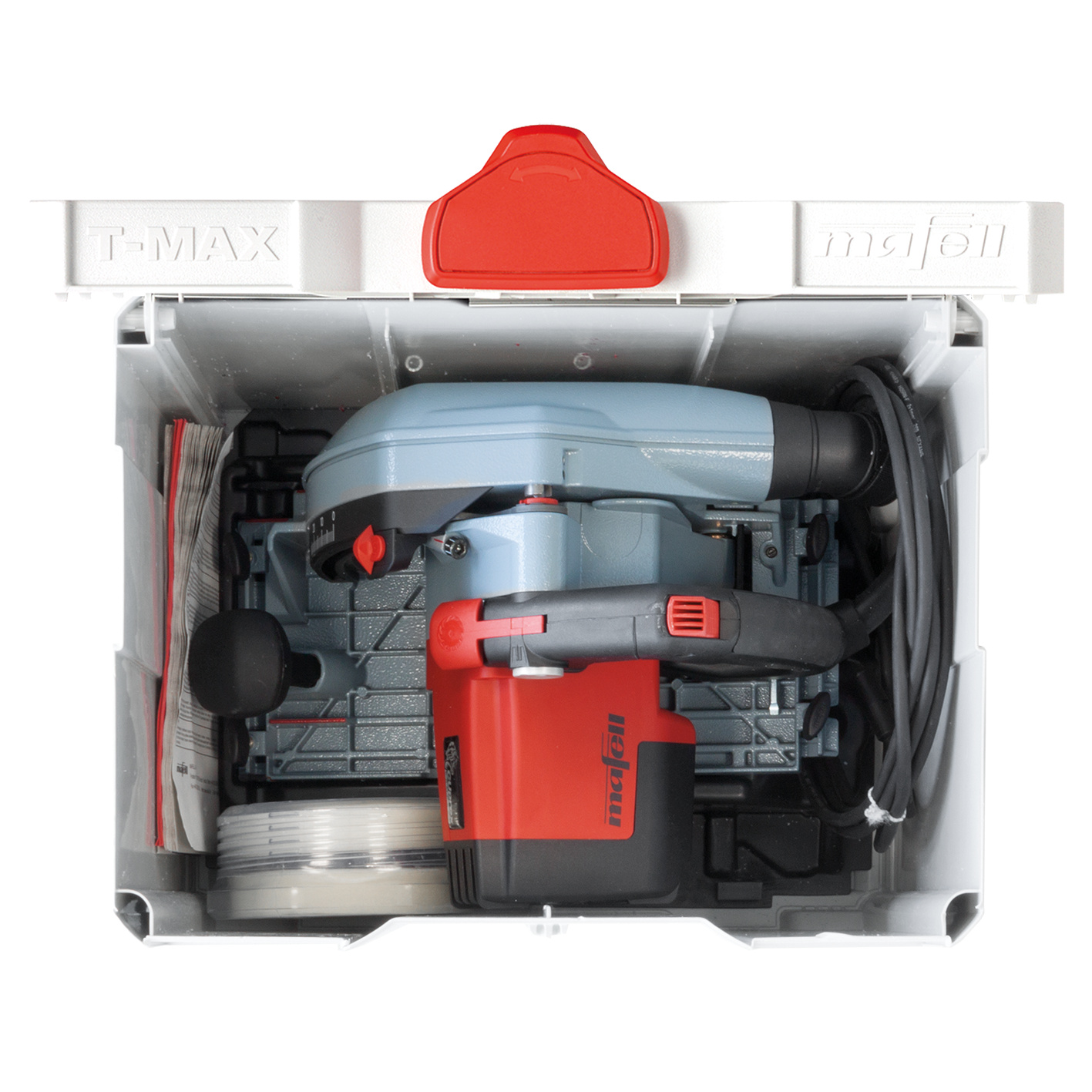

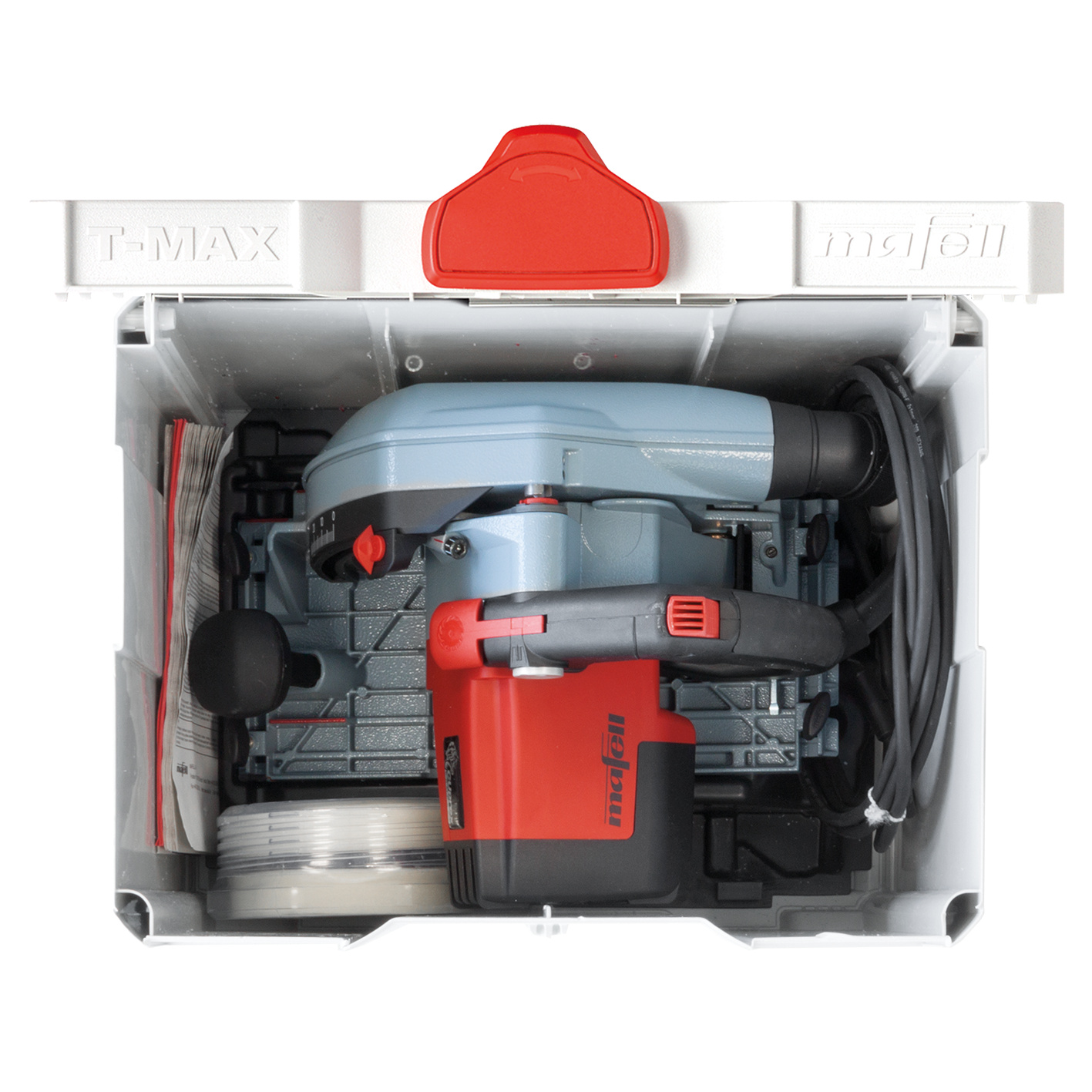

Multi-cutter MF 26 cc AF-MAX in the T-MAX

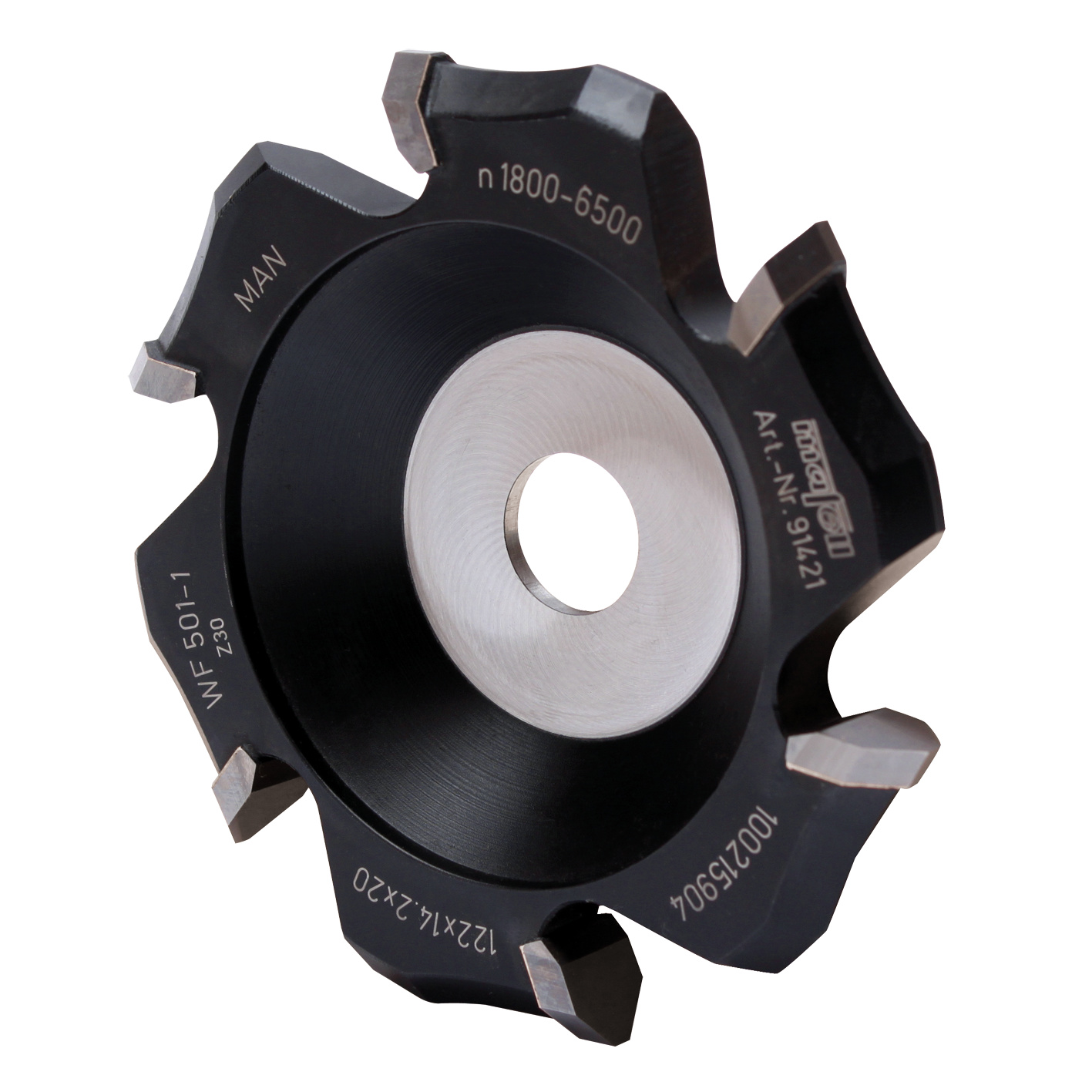

- 1 TCT saw blade 120 x 1,2/1,8 x 20 mm, Z 40, FZ/TR, for fine cuts in wood; Ref. No. 092559

- 1 Aluminum composite cutter MF-AF 90, for 90° V-grooves up to 8 mm deep; Ref. No. 206076

- 1 Parallel guide fence

- 1 Mains cable 4 m (13.1 ft); Ref. No. 087323

- With aluminum composite cutter MF-AF 90

- Transport and storage box T-MAX

SEK 19,063.00*

Selling and shipping is done by the Mafell specialist dealer. The Mafell specialist dealer can be selected during the ordering process.

Overview of the Mafell specialist dealers

Delivery time: appr. 10 - 14 workdays

Technical data

| Cutting depth | 0 - 26 mm |

| Cutting depth | 0 - 1 in |

| Nominal No. of strokes – no load | 3600 - 6250 1/min |

| Nominal power input | 1400 W |

| Nominal power input | 1.9 hp |

| Universal motor | 230 V / 50 Hz |

| Weight | 5 kg |

| Weight | 11 lbs |

Product details

The design of the MF 26 cc is characterized by the use of extremely rugged, high-quality and precision-made parts, including the lightweight magnesium die-cast housing and impact-resistant, fiber glass-reinforced plastic components.

The MF 26 cc multi-cutter can be operated to a cutting depth of 26 mm (1 in.) on the guide rail and as a plunge-cut saw.

Whether sawing, routing or cutting grooves, genuine precision is best achieved with the aid of the guide rail system F.

Continuously variable speed up to 6250 rpm. For shaping, sawing and slotting an abundance of different materials.

Applications

- Lengthwise and crosswise grooves

- V-grooves

- For routing wallboard prior to folding, bending techniques

- Routing and folding techniques with aluminum composite panels, sawing.

- Materials usage: solid wood, MDF, drywall, aluminum composite panels

Advantages

- Turn the adjusting screw to set the cutting depth on the sliding scale with an accuracy of 1/10 mm.

- Enhanced precision assured – The glider slides on the surface of the workpiece and thus prevents tilting. It helps to hold the MF 26 cc securely in position when it is mounted on the guide rail as well. When bending and folding aluminum composite panels and wallboard in particular, the glider ensures exact cutting depth accuracy.

- The guard opens with a single action. When it is opened, the starting lockout and sawblade lock engage automatically.

- With or without a rail – simply turn the pointer to show the exact cutting depth.

- With or without a rail – simply turn the pointer to show the exact cutting depth.

Usage

Downloads / Safety notes

Accessories / Tools

Accessories / Tools

Guide rail F 80

0,8 m (2,6 ft) long

Guide rail F 110

1.1 m (3.6 ft) long

Guide rail F 160

1.6 m (5.2 ft) long

Guide rail F 210

2,1 m (6,9 ft) long

Guide rail F 310

3,1 m (10,2 ft) long

Connecting piece F-VS

for joining two guide rails

Guide pocket F 160

for guide rails up to 1,6 m

Guide pocket set

2 x F 160 + F-VS + 2 x F-SZ 180 MM + TZ-FST1600

Non-slip profile F-HP 6,8 M

6.8 m (22.3 ft.) long

Splinter guard F-SS 3,4M

3.4 m (11.2 ft.) long

Roller edge guide MF-UA

Guide track M

max. cutting length 400 mm (15 3/4 in.)

Guide track ML

max. cutting length 770 mm (30 5/16 in.)

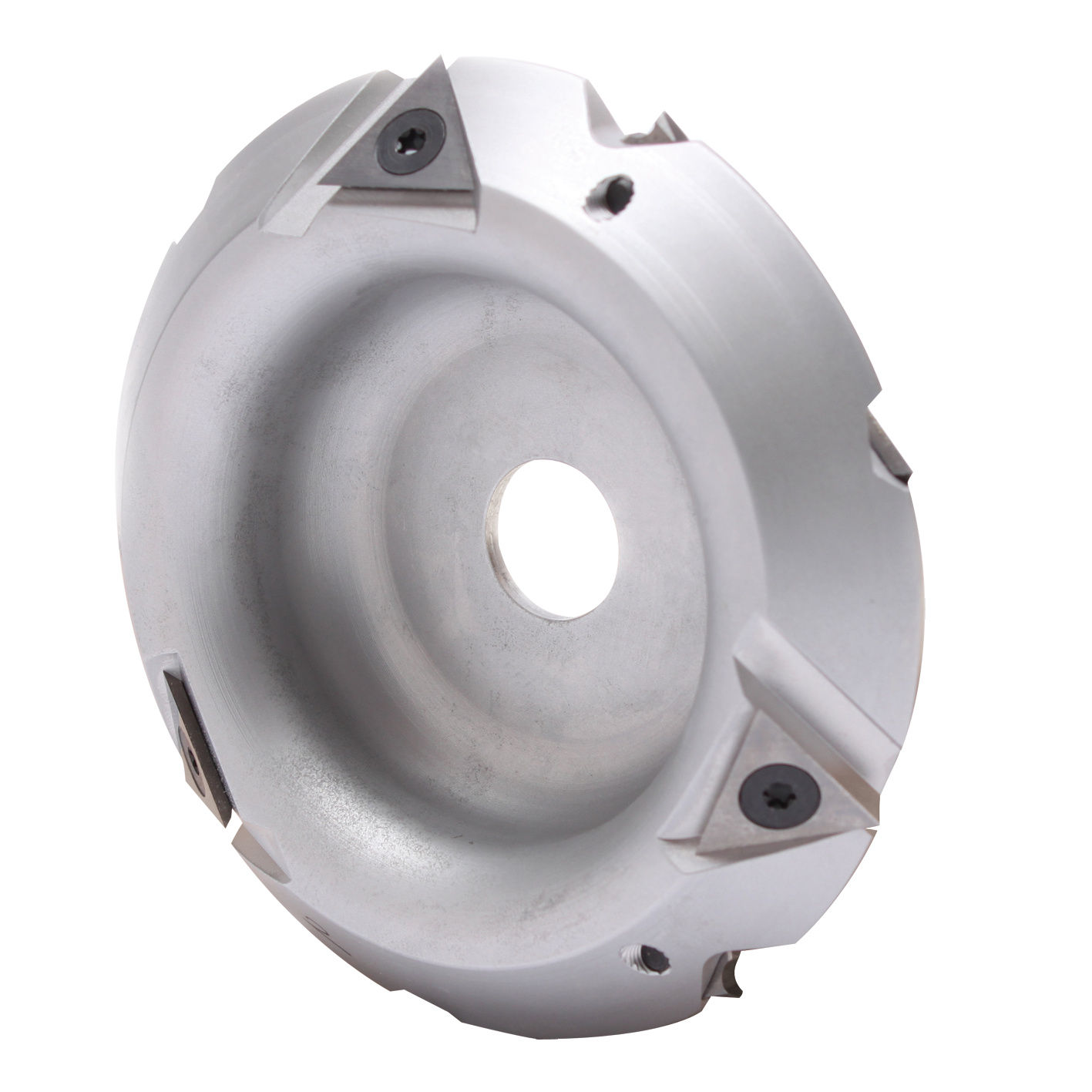

Expanding groove cutter MF-VN 25

Cutting width 15.4 - 25 mm

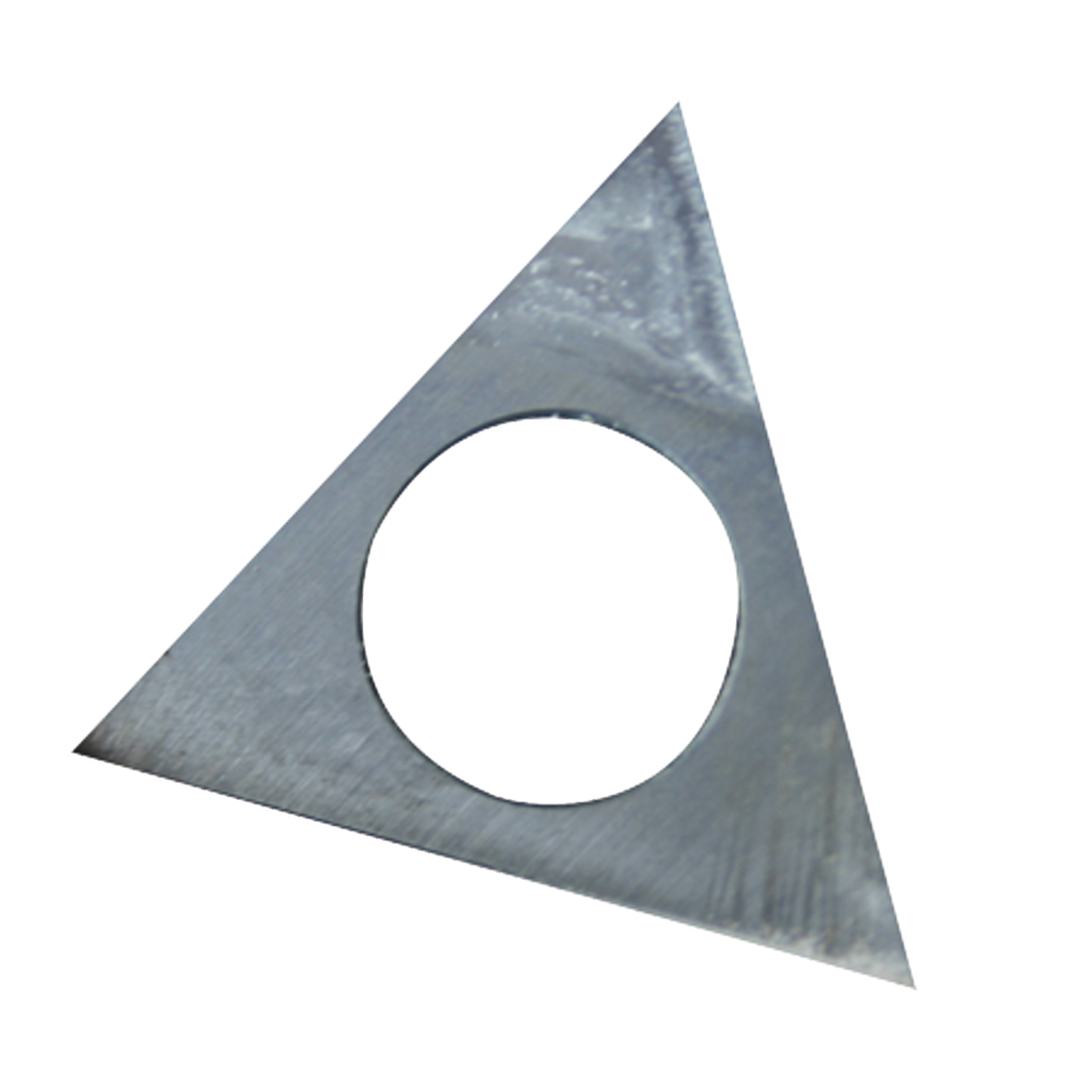

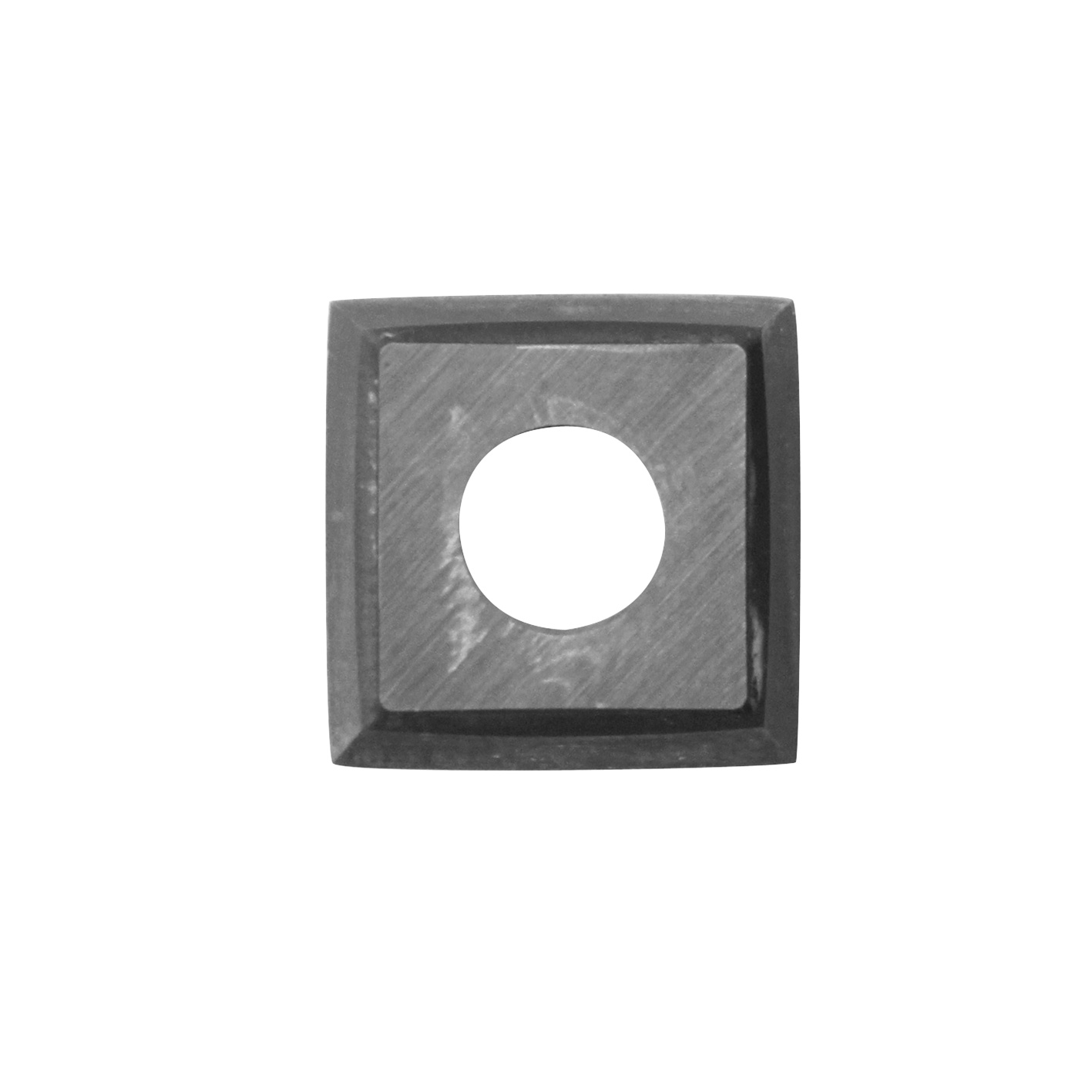

Reversible TCT knife

15 x 15 x 2,5

Google Maps Consent

You don't have enabled the store locator cookies yet. To do so, click on "Open cookie configurator", enable "Store Locator" in the off canvas and click "Save".

This page requires Google Maps to work properly. Click on "Continue" to agree.