Zero joint edge bander HIT-M 103 SA

- 1 swivelling driven roller

- 1 swivelling support plate

- 1 cleaning brush

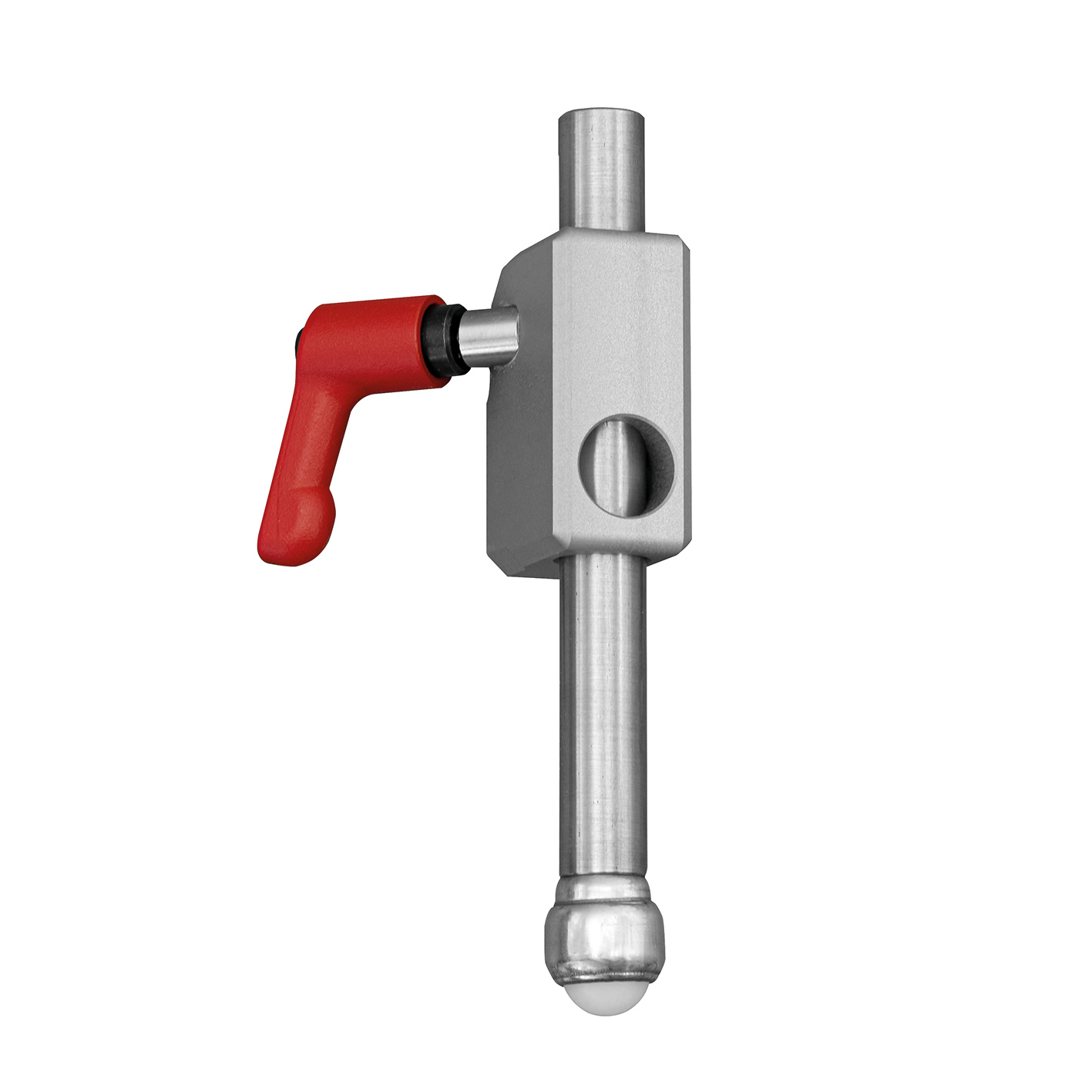

- 2 locking bolts (short and long)

- 1 hexagon socket 3 mm (¹/8 in)

- 1 hexagon socket 4 mm (3/16 in)

- 1 hexagon socket 5 mm (3/16 in)

- 1 hexagon socket 6 mm (1/4 in)

- 1 connection package 5 m (16,4 ft) (voltage/compressed air)

- Permanent zero joint

- No glue change required

- Bevelled edges possible

- No set-up times

- For large edge heights

SEK 110,033.00*

Selling and shipping is done by the Mafell specialist dealer. The Mafell specialist dealer can be selected during the ordering process.

Overview of the Mafell specialist dealers

Delivery time: appr. 10 - 14 workdays

Technical data

| Nominal voltage | 230 V |

| Nominal power input | 3050 W |

| Nominal power input | 4.1 hp |

| Edge height | 10 - 103 mm |

| Edge height | 3/8 - 4 ¹/16 in |

| Tilt range | 0 - 50 ° |

| Edge thickness | 0,4 -3,0 mm |

| Edge thickness | ¹/64 - ¹/8 in |

| Min. inside radius | 10 mm |

| Min. inside radius | 3/8 in |

| Heating time | 30 s |

| Temperature max. | 520 ° C |

| Temperature max. | 968 ° F |

| Infinitely variable feed rate | 1 - 5,5 m/min |

| Infinitely variable feed rate | 3.3 - 18.0 ft/min |

| Connection compressed air | 6 - 10 bar |

| Connection compressed air | 87 - 145 psi |

| Weight | 10,9 kg |

| Weight | 24.0 lbs |

| Dimensions (L x W x H) | 220 x 160 x 400 mm |

| Dimensions (L x W x H) | 8 11/16 x 6 5/16 x 15 3/4 in |

Product details

The HIT-M is the first and only mobile device for creating an optical zero joint. With the hot air injection technique, all customary zero joint edges with applied functional layer can be processed - without the use of additional adhesive.

The HIT-M can be flexibly used and is ideal for intricate components. Especially with free-forms or tight radii it shows its great strengths.

Perfectly straight, bevelled, curved and round panel materials as well as moulded parts can be processed. Inclined cut surfaces of up to 55° can be easily achieved.

The working temperature is reached a few seconds after switching on the unit. With the HIT-M there is no need for time-consuming colour changes or cleaning of glue pans.

Applications

- Optimally suited for larger moulded parts, for example, and for use on the construction site.

- For panel materials with edge heights of up to 103 mm

Advantages

- For bevelled plate edges, the support plate can be swivelled up to 50°.

- Automatic edge feed with edge detection as stop function.

- A clear arrangement of the control elements makes working with the device simple and intuitive.

- Connection socket for optionally available foot switch.

Usage