Tenoner ZAF 250 Vario

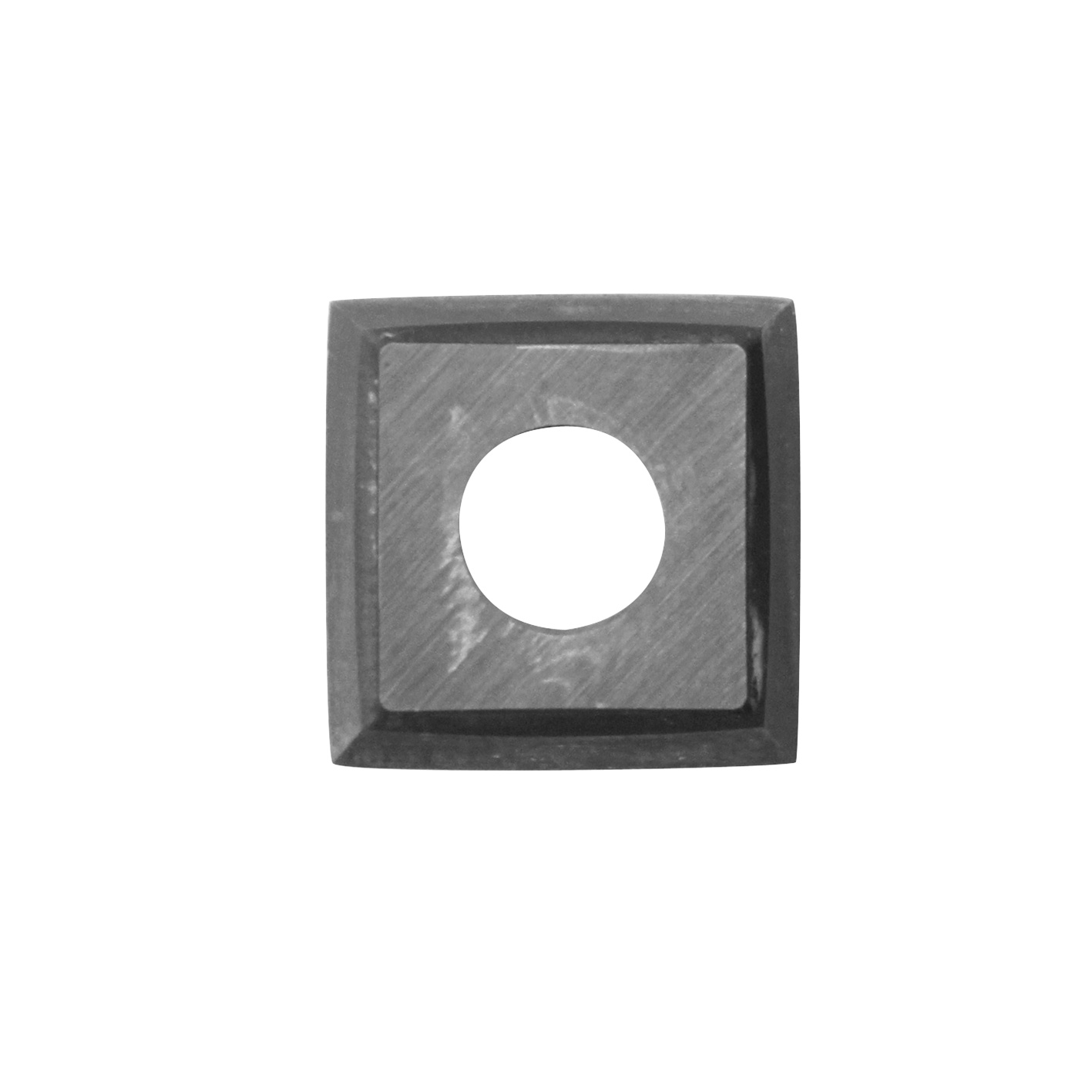

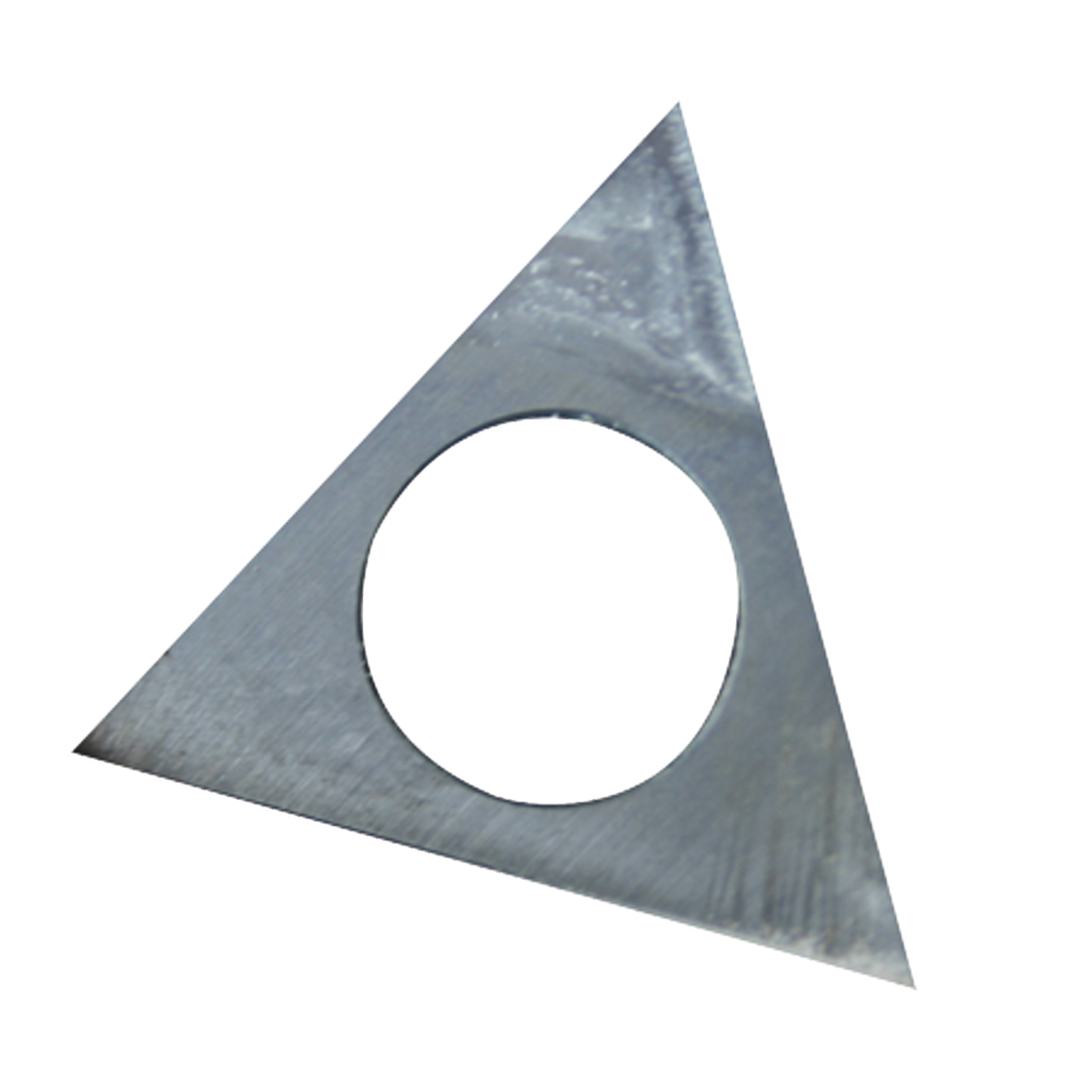

- 1 Cutter head, complete with reversible knives TCT; Ref. No. 202105

- Support table; Ref. No. 205025

- Tilt range of cutting unit up to 60 °

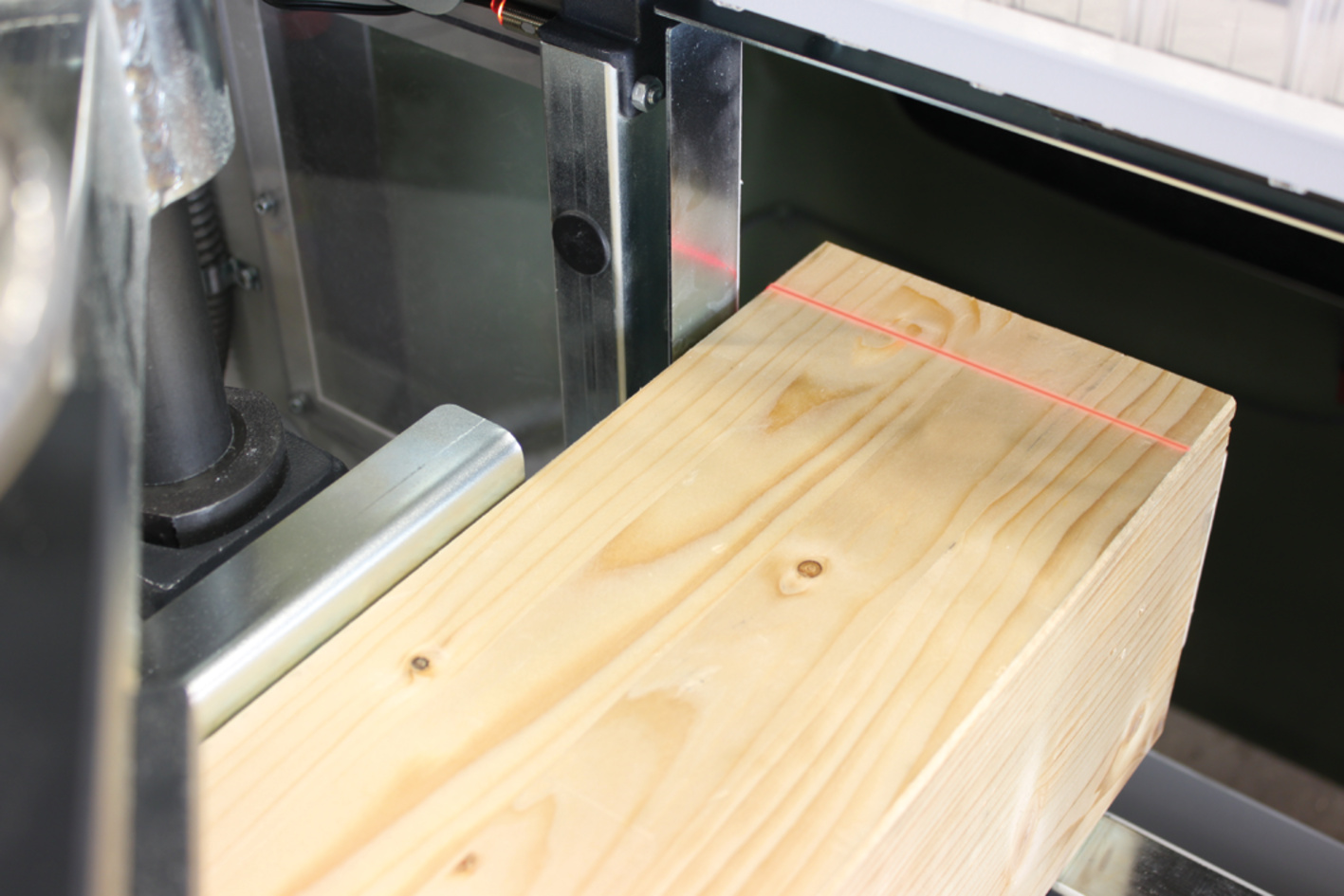

- Laser positioning

- Special cutting tool

SEK 293,425.00*

Selling and shipping is done by the Mafell specialist dealer. The Mafell specialist dealer can be selected during the ordering process.

Overview of the Mafell specialist dealers

Delivery time: appr. 10 - 14 workdays

Technical data

| Maximum timber sizes (W x H) for right angled tenons | 500 x 250 mm |

| Maximum timber sizes (W x H) for right angled tenons | 19 11/16 x 9 13/16 in |

| Maximum timber sizes (W x H) for 60° angled tenons | 220 x 250 mm |

| Maximum timber sizes (W x H) for 60° angled tenons | 8 11/16 x 9 13/16 in |

| Length of support (with scale for adjusting length stop) | 3000 mm |

| Length of support (with scale for adjusting length stop) | 118 1/8 in |

| Feed rate speed | 0,9 - 2,2 m/s |

| Feed rate speed | 2.9 - 7.2 ft/s |

| Place requirement | 1,5 x 4 m |

| Nominal No. of strokes – no load | 6670 1/min |

| Nominal power input | 6000 W |

| Nominal power input | 8.0 hp |

| Weight | 392,1 kg |

| Weight | 864.4 lbs |

| Three-phase AC motor | 400 V / 50 Hz |

Product details

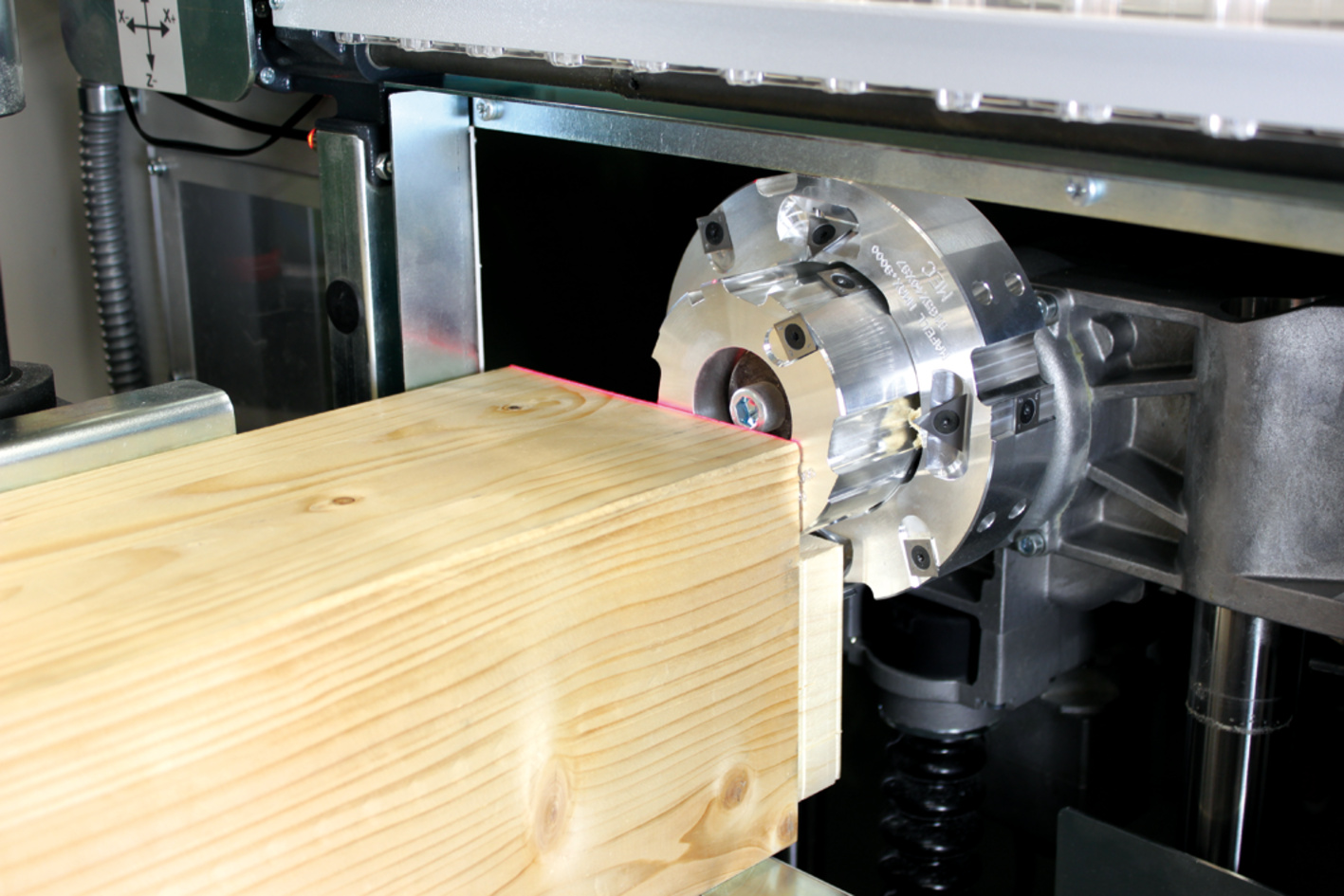

The ZAF 250 Vario executes the full range of tenons quickly, accurately, efficiently and precisely.

For straight or angled tenons, corner or ridge half-lap joints, you can always count on the ZAF 250 Vario Tenoner.

To ensure exact length measurements, the stop is adjusted on a scale.

Developed specifically for the ZAF 250 Vario, the cutting tool can be rapidly adapted for different tenon lengths and half-lap joints.

The ZAF 250 Vario has precision setting options and a clearly laid-out control panel. Precise positioning of the timber is facilitated by a new built-in laser. The result is cuts which are accurate to the nearest millimeter (inch) in all types of timber!

After setting the desired tenon geometry, the cutter head automatically executes the required shape - including angled, haunched and chamfered cuts.

For hardwood applications the ZAF 250 Vario has an adjustable feed rate. Chip waste is extractable as a matter of course.

Applications

- Cutting tenons and laps up to 60°

- Compatible materials include solid wood and laminated beams

Advantages

- Considerable time-saving – due to quick and easy adjustment of length, angle and tenon dimensions.

- Maximum timber dimensions 500 x 250 mm (19 11/16 x 9 13/16 in.) at 0° and 220 x 250 mm (8 11/16 x 9 13/16 in.) at 60°.

- Minimum space requirement – thanks to the swiveling cutter head, the timber always remains in the same position.

- No chip waste – fully extractable.

Usage