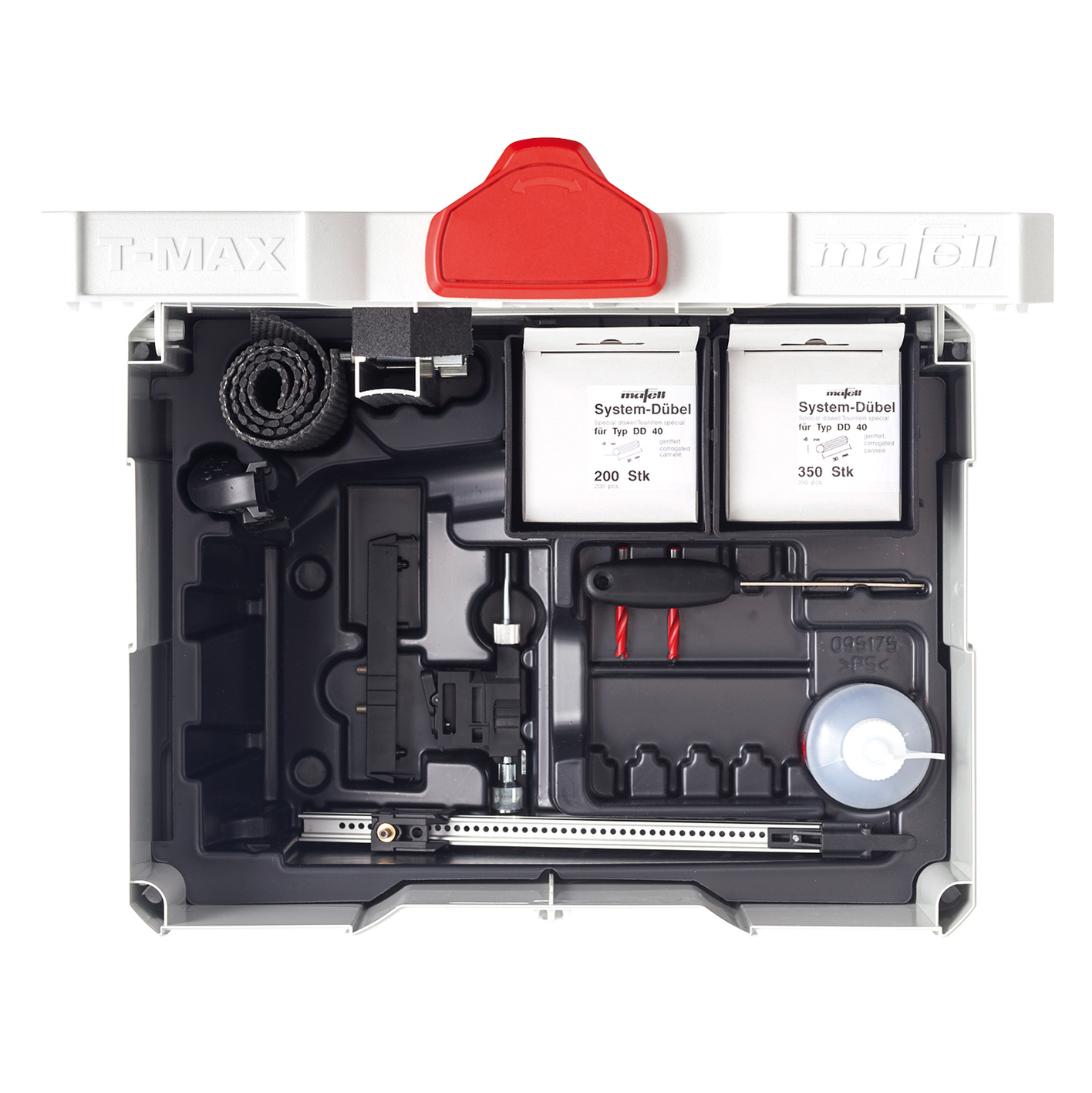

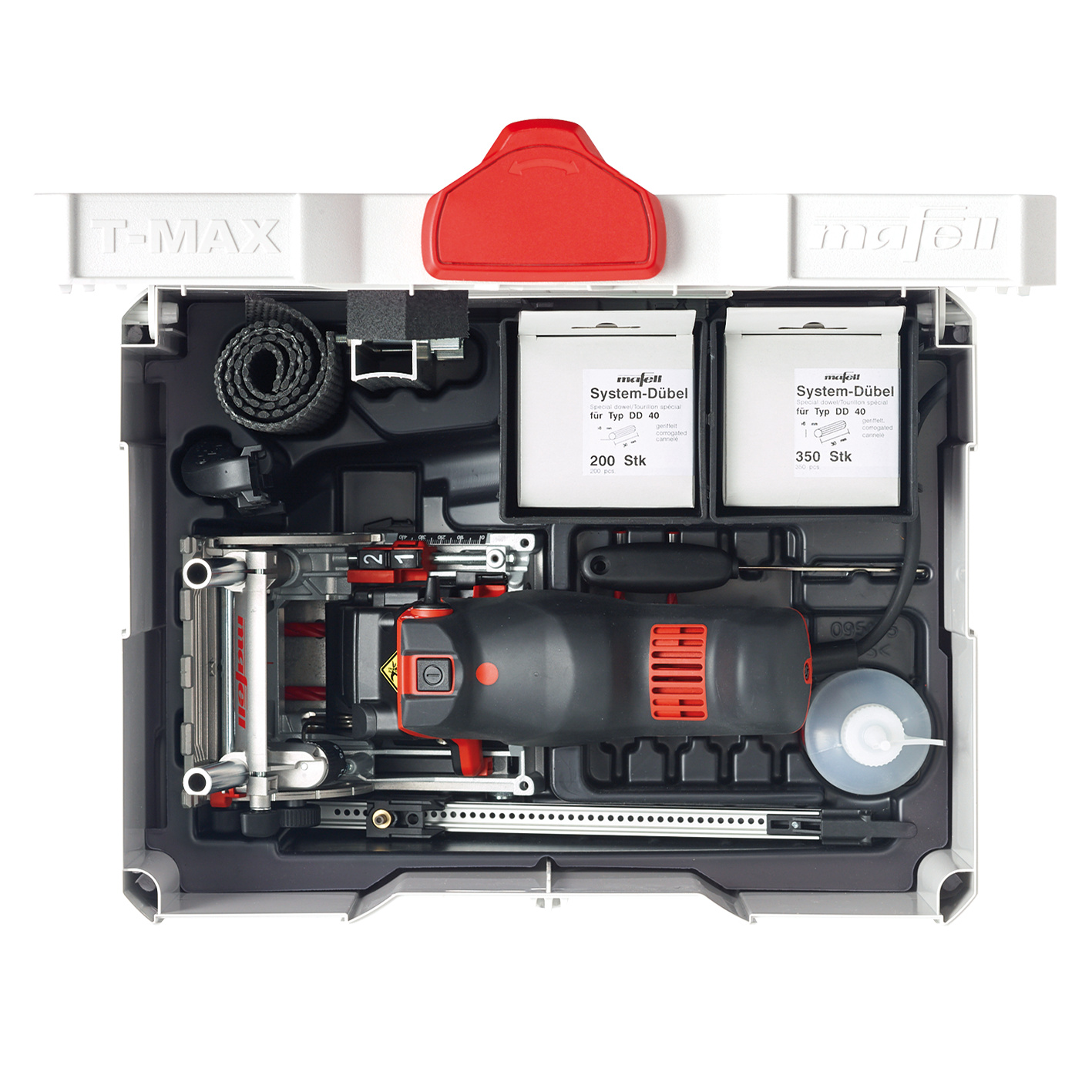

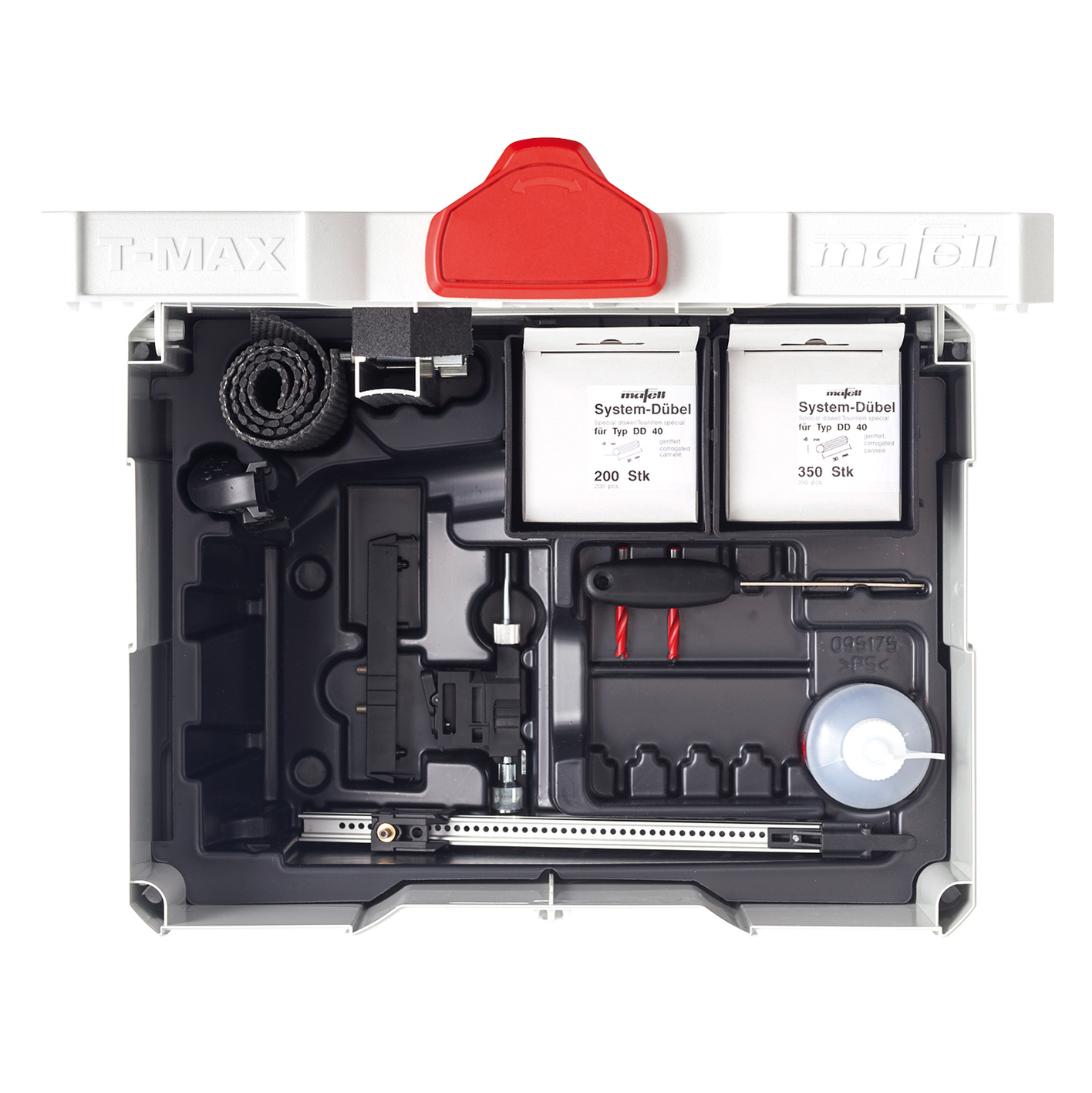

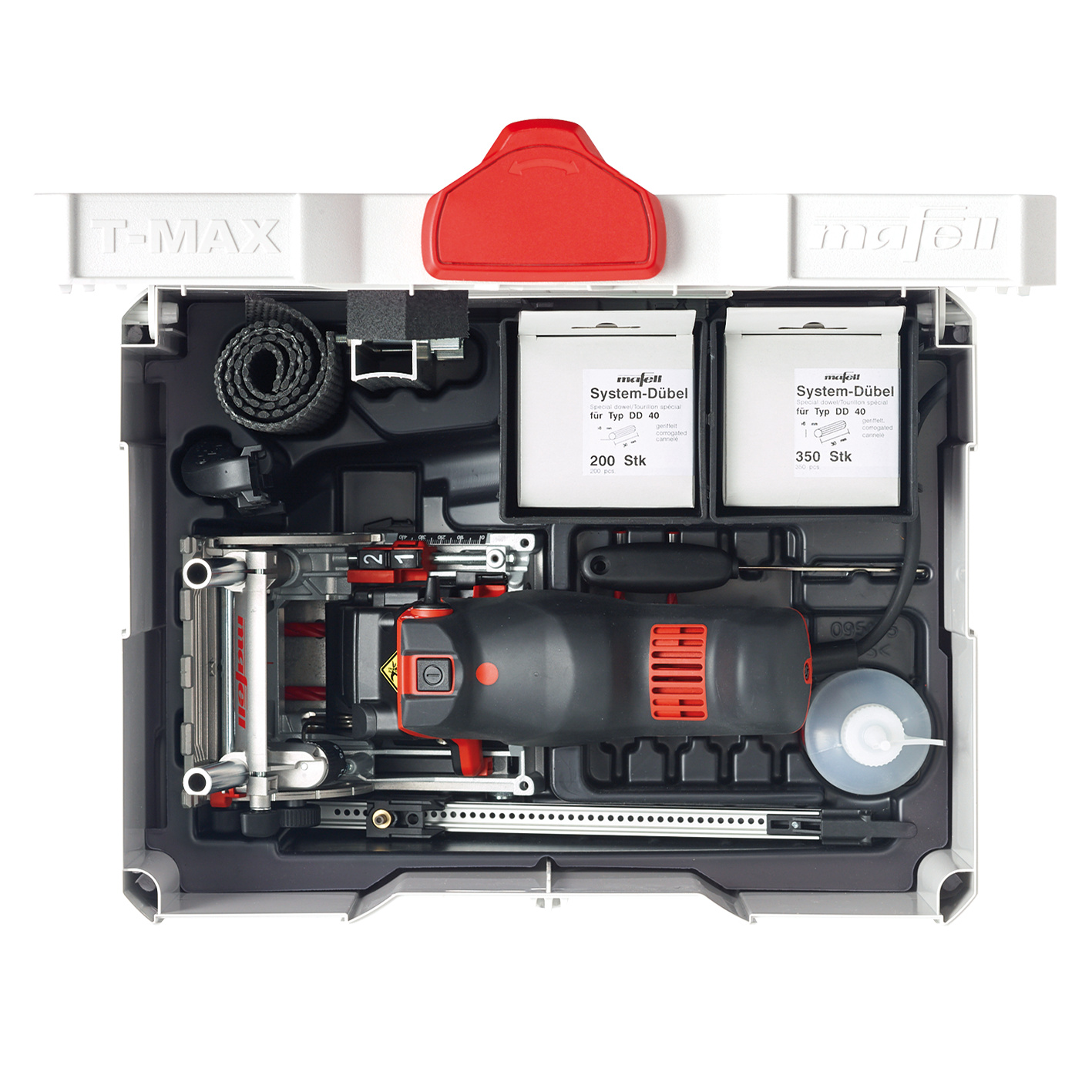

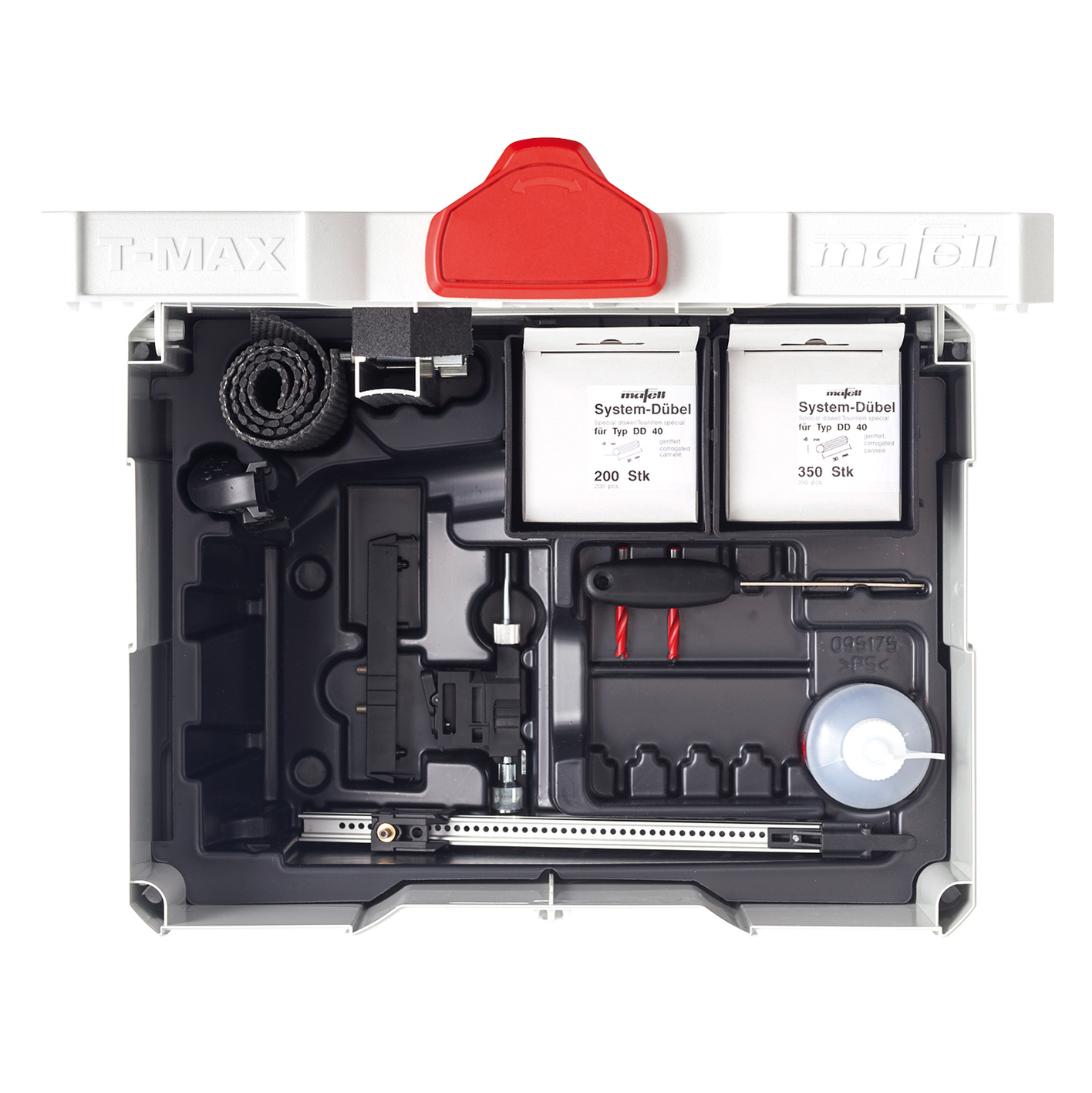

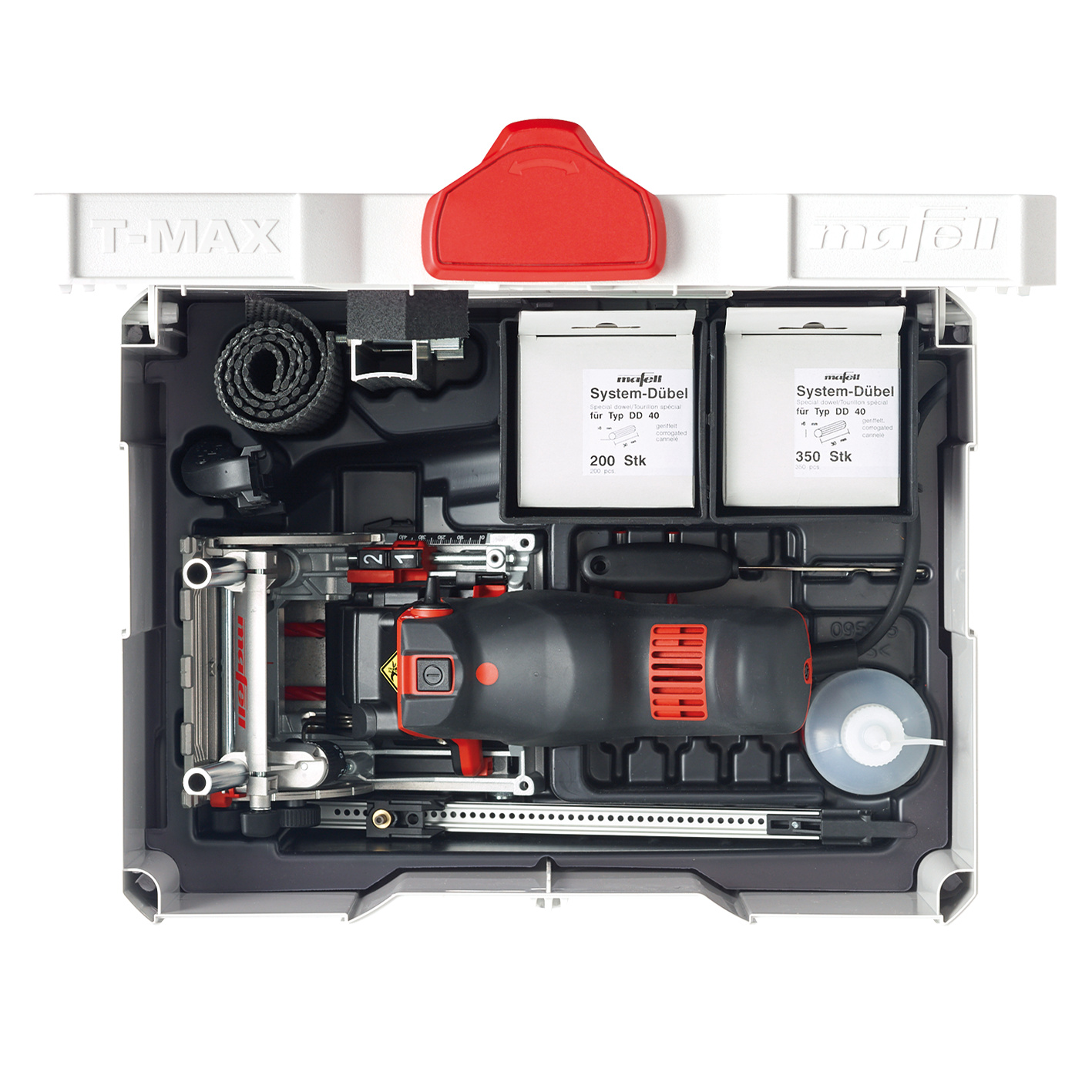

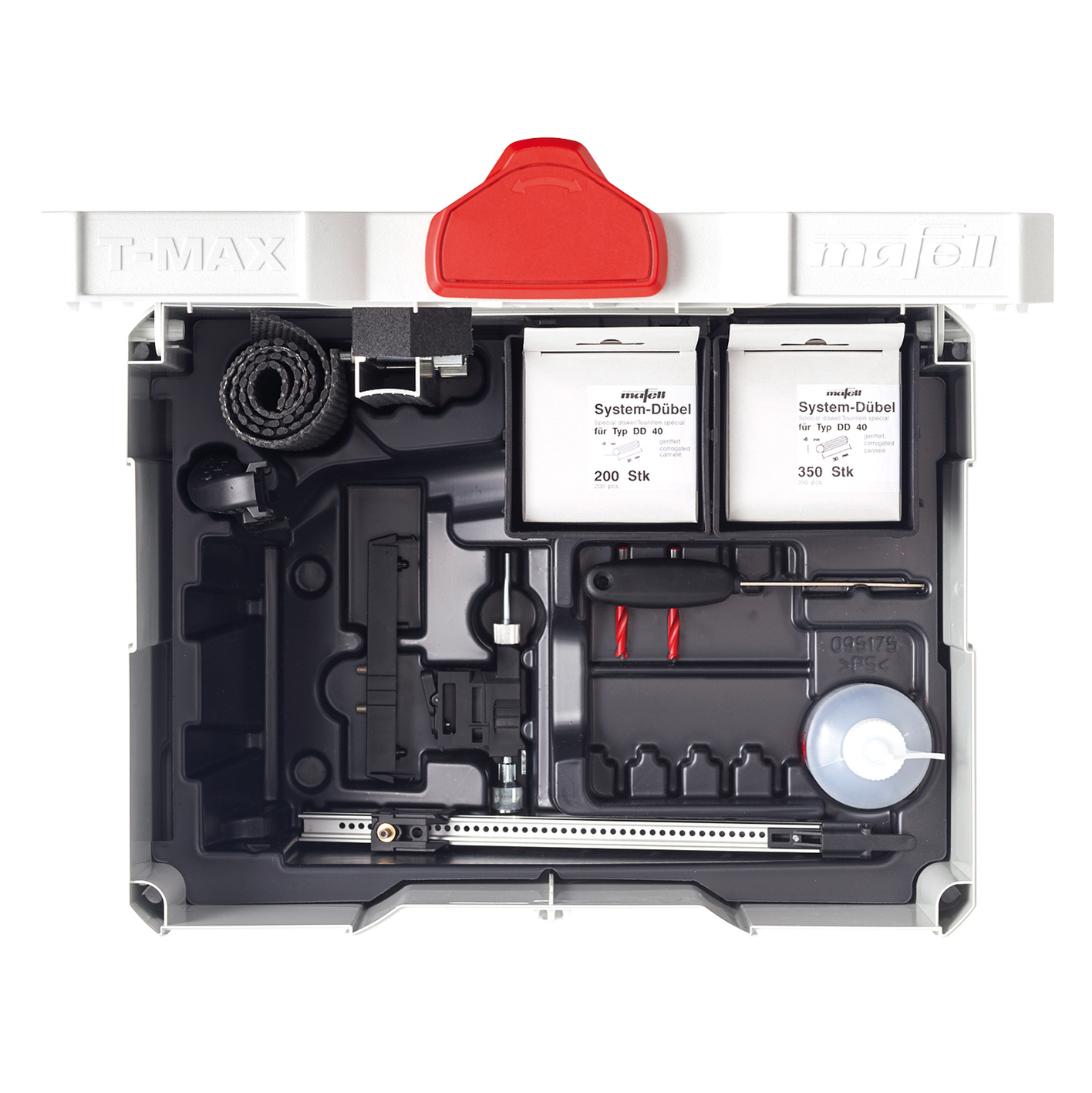

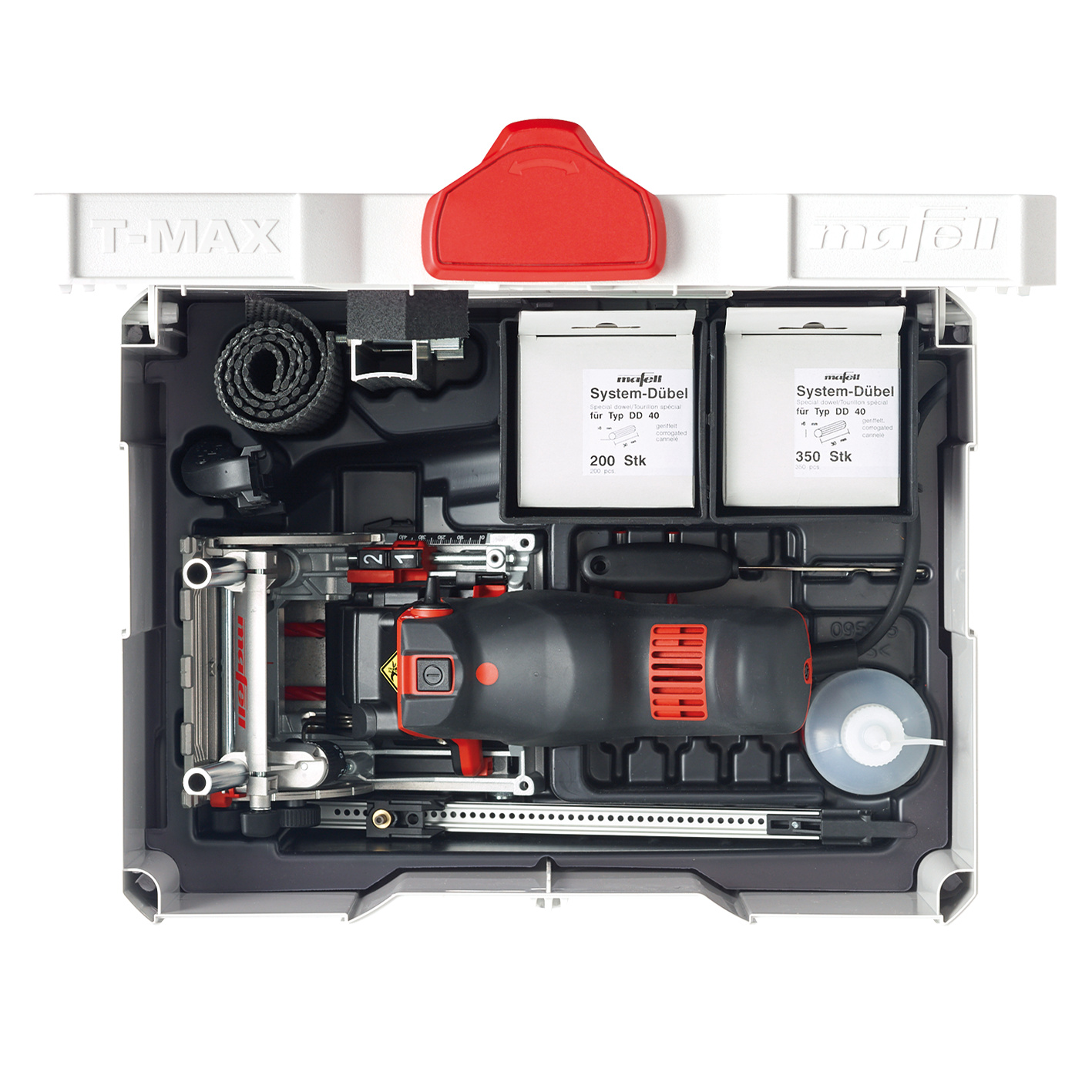

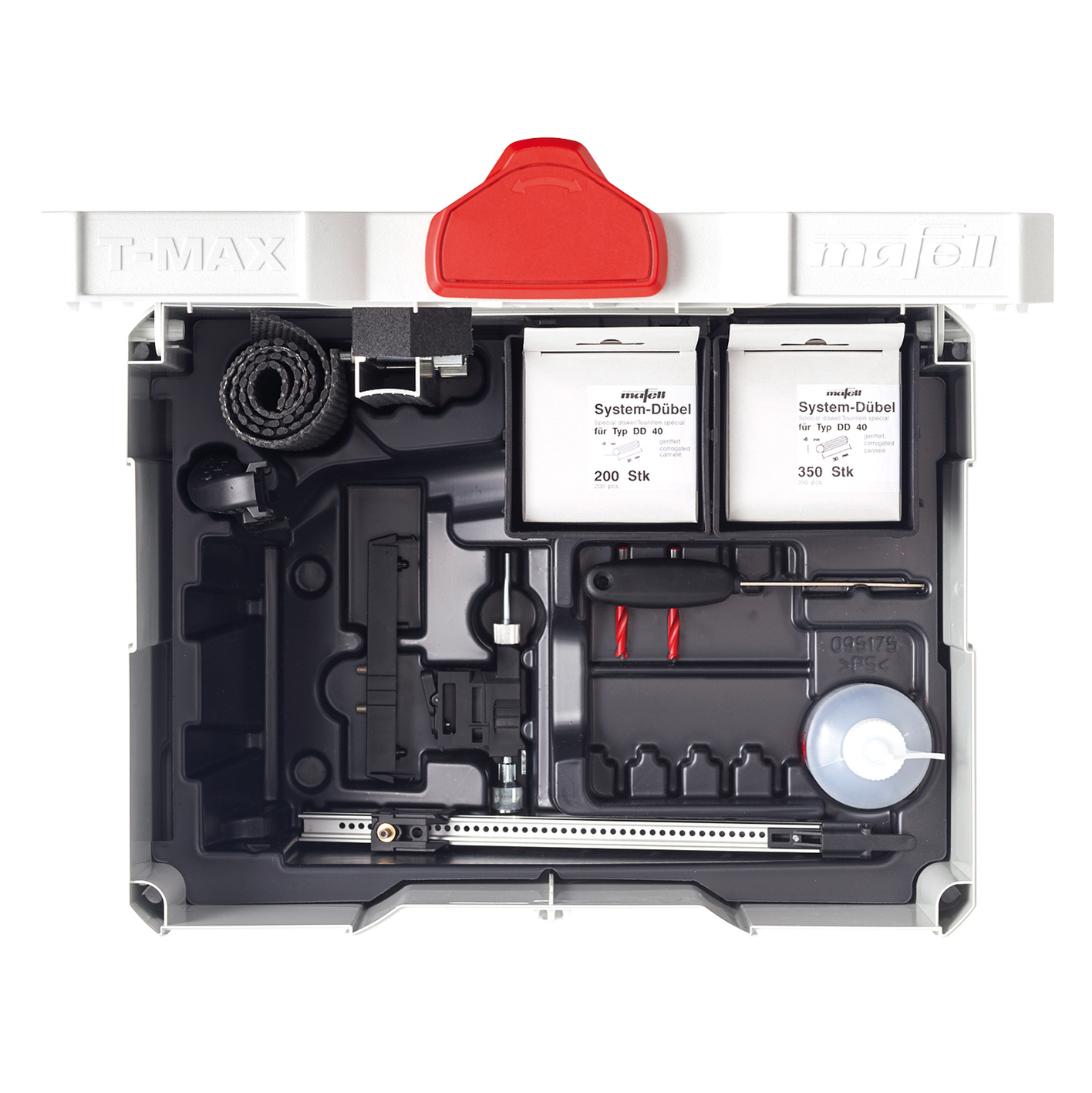

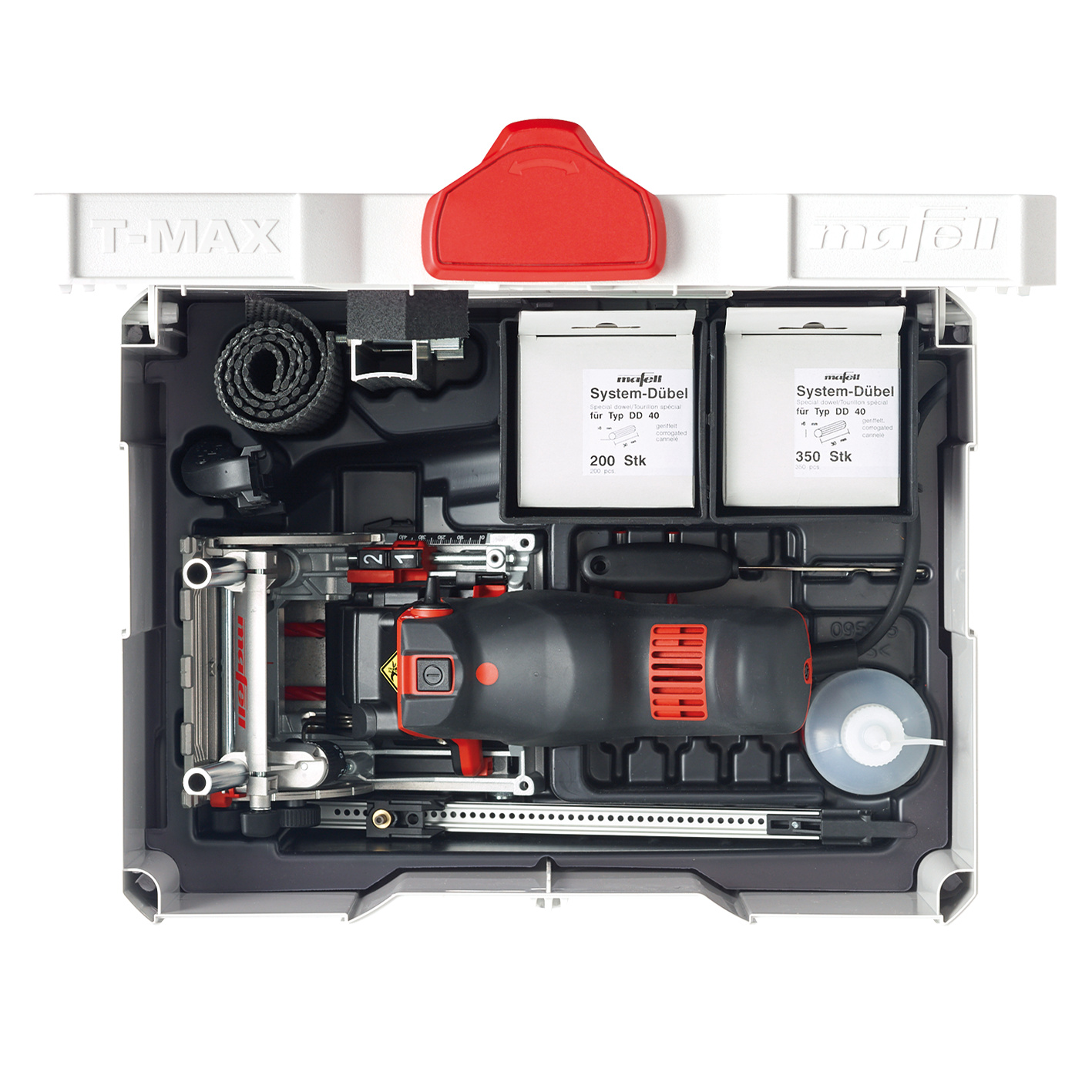

DuoDoweler DDF 40 MidiMAX in T-MAX

- 1 auxiliary rest ZA

- 1 set of additional stops ZAG

- 1 hose connector

- 1 position indicator PAZ

- 2 Anti-slip mats, wrapped; Ref. No. 095063

- 1 Bottle for glue 250 ml (without glue); Ref. No. 095059

- 1 Allen key with handle; Ref. No. 093282

- 1 Mains cable 4 m (13.1 ft); Ref. No. 077015

- 2 carbide dowel drills-HW, dia. 8 mm

- 1 pack of wooden dowels, 8 x 30 mm, qty. 200

- New ergonomic design for easy handling

- Patented alignment system

- Slimline machine with a flat baseplate

SEK 10,450.00*

Selling and shipping is done by the Mafell specialist dealer. The Mafell specialist dealer can be selected during the ordering process.

Overview of the Mafell specialist dealers

Delivery time: appr. 10 - 14 workdays

Technical data

| Drilling depth | 0 - 40 mm |

| Drilling depth | 0 - 1 9/16 in |

| Drill spacing | 32 mm |

| Drill spacing | 1 1/4 in |

| Chuck Ø | 8 mm |

| Chuck Ø | 5/16 in |

| Tool Ø max. | 12,2 mm |

| Tool Ø max. | 1/2 in |

| Tool Ø min. | 3 mm |

| Tool Ø min. | 1/8 in |

| Tilt range | 0 - 90 ° |

| Nominal No. of strokes – no load | 8000 1/min |

| Nominal power input | 900 W |

| Nominal power input | 1.2 hp |

| Extraction connection diameter | 29 mm |

| Extraction connection diameter | 1 1/8 in |

| Weight | 2,8 kg |

| Weight | 6.2 lbs |

| Dimensions (W x L x H) | 145 x 300 x 164 mm |

| Dimensions (W x L x H) | 5 11/16 x 11 13/16 x 6 7/16 in |

| Universal motor | 230 V / 50 Hz |

Product details

The DuoDoweler DDF 40 introduces greater ease and efficiency to the task of drilling accurate dowel holes. Its hallmarks are a broad range of applications, a new ergonomic design for easy handling, and absolutely aligned, stable joints.

Whether in the workshop or on site, no other hand-held power tool can produce such high-quality joints.

When producing corner joints, partitions or rows of holes, the DDF 40 offers not only the precision of a stationary machine, but also the cost savings associated with standard wooden dowels.

In addition, the technique of using dowels in pairs already achieves outstanding stability at the dry assembly stage.

Applications

- Rows of holes

- Drilling for fittings/hardware

- Ideal for carcass and staircase construction in the workshop and on site

- Compatible materials include solid wood and board materials

- All types of joints from 3 - 12 mm (1/8 in. - 1/2 in.)

Advantages

- The rotary knob and scale allow the tilting fence to be accurately repositioned up to a height of 62 mm (2 7/16 in.) . Regularly occurring dimensions can be preset by way of the turret.

- Two spring-loaded pins in the baseplate enable the user to drill holes at a fixed distance of 15,5 mm (5/8 in.) from the edge of the work; repetitive drilling without any measuring or marking is simple.

- The ergonomic motor housing, with a molded grip at the front and a hump at the rear, gives the operator a perfect hold no matter what the job, while ensuring the ideal transmission of force to the machine.

- The tilting fence is located on two columns and fastened with a single adjusting screw. For miter joints, it tilts continuously from 0 through 90 degrees. Indexing stops are provided at 22.5°, 45° and 67.5°.

Usage

Downloads / Safety notes

Accessories / Tools

Accessories / Tools

Dowel drill bit-HS

Ø 3 mm

Dowel drill bit-HW

Ø 5 mm (3/16 in.)

Dowel drill bit-HW

Ø 6 mm

Dowel drill bit-HW

Ø 6,1 mm

Dowel drill bit-HW

Ø 8 mm

Dowel drill bit-HW

Ø 8,1 mm

Dowel drill bit-HW

Ø 8,2 mm

Dowel drill bit-HW

Ø 10 mm (3/8 in.)

Dowel drill bit-HW

Ø 10,1 mm

Dowel drill bit-HW

Ø 10,2 mm

Dowel drill bit-HW

Ø 12 mm (1/2 in.)

Dowel drill bit-HW

Ø 12,2 mm

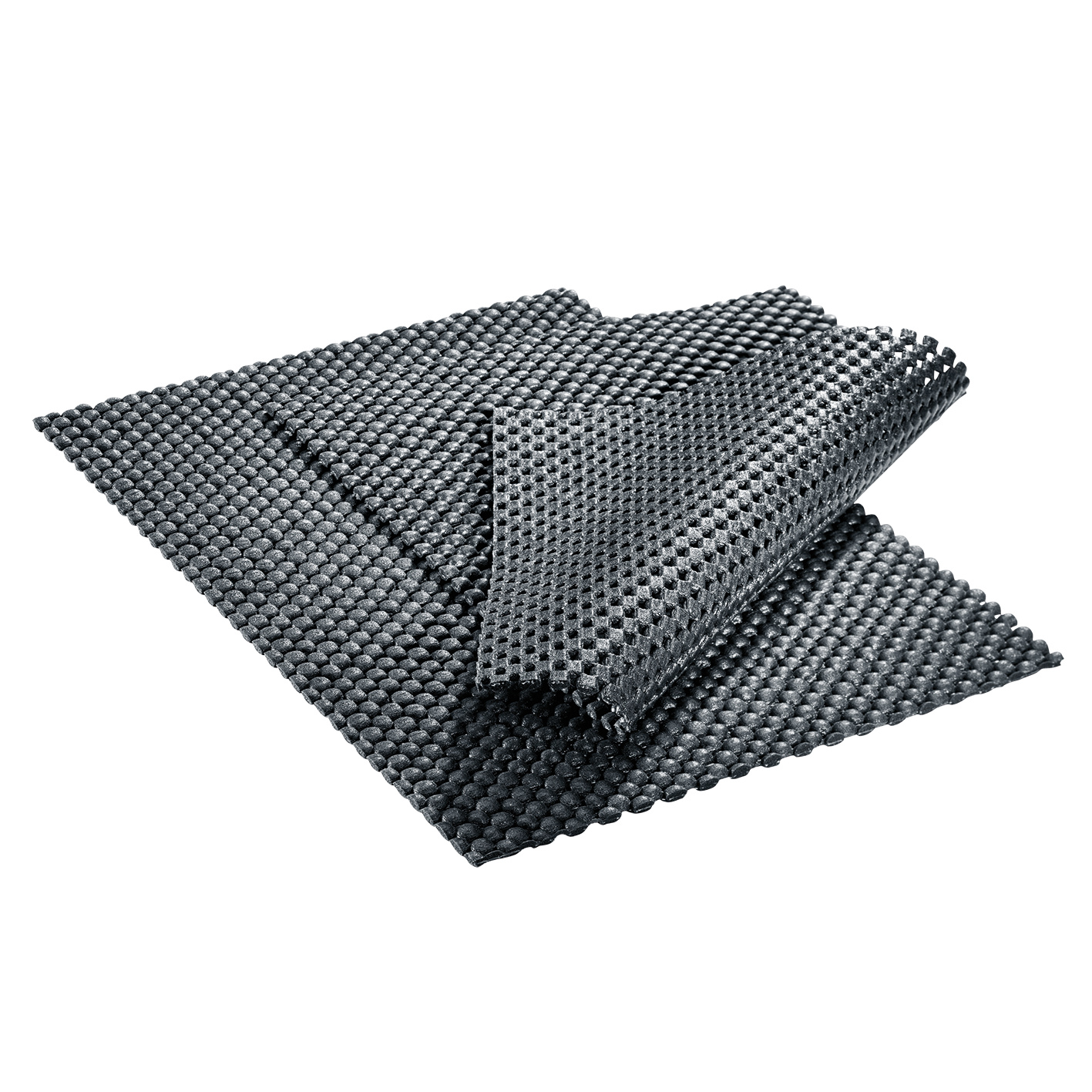

Anti-slip mats

2 pieces

Google Maps Consent

You don't have enabled the store locator cookies yet. To do so, click on "Open cookie configurator", enable "Store Locator" in the off canvas and click "Save".

This page requires Google Maps to work properly. Click on "Continue" to agree.