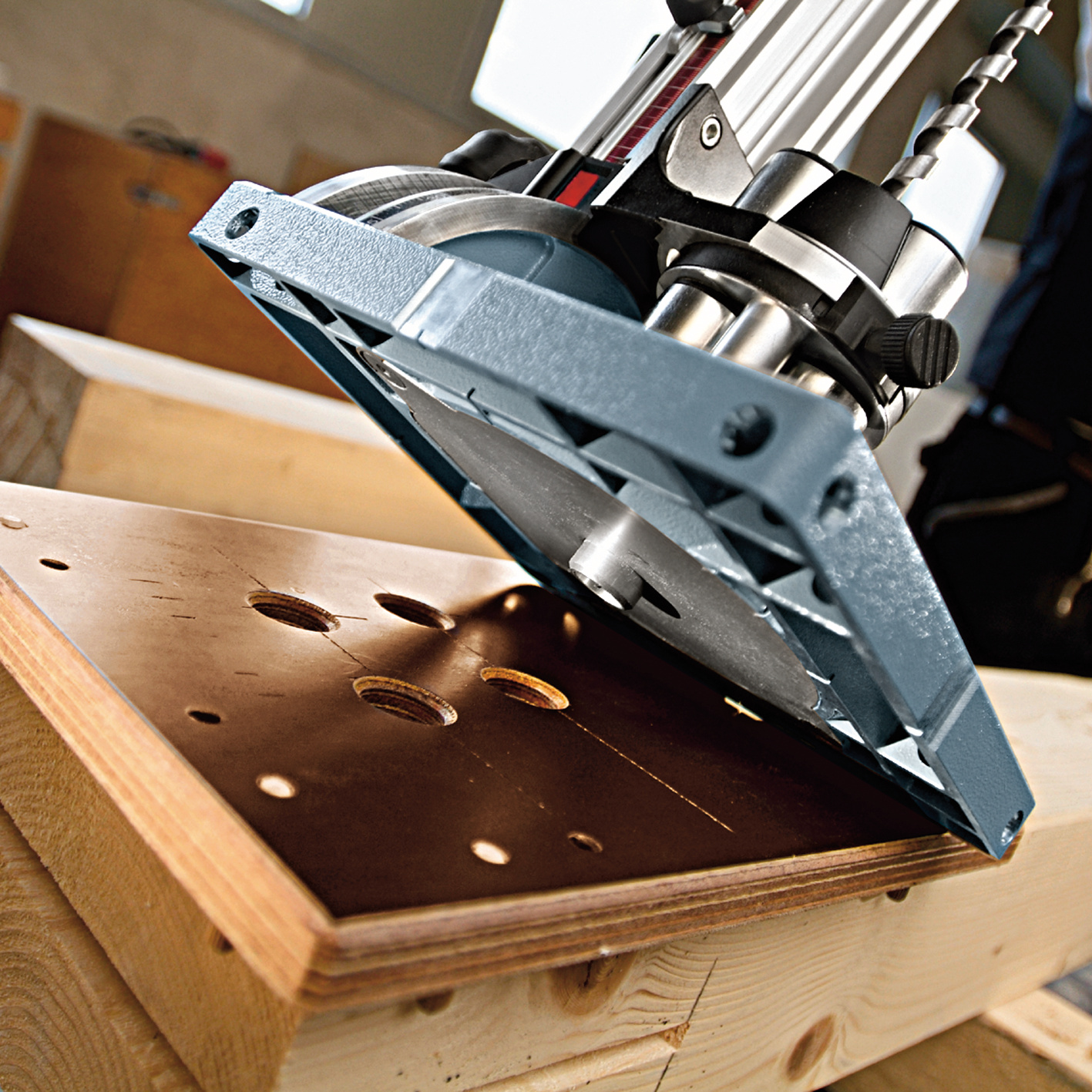

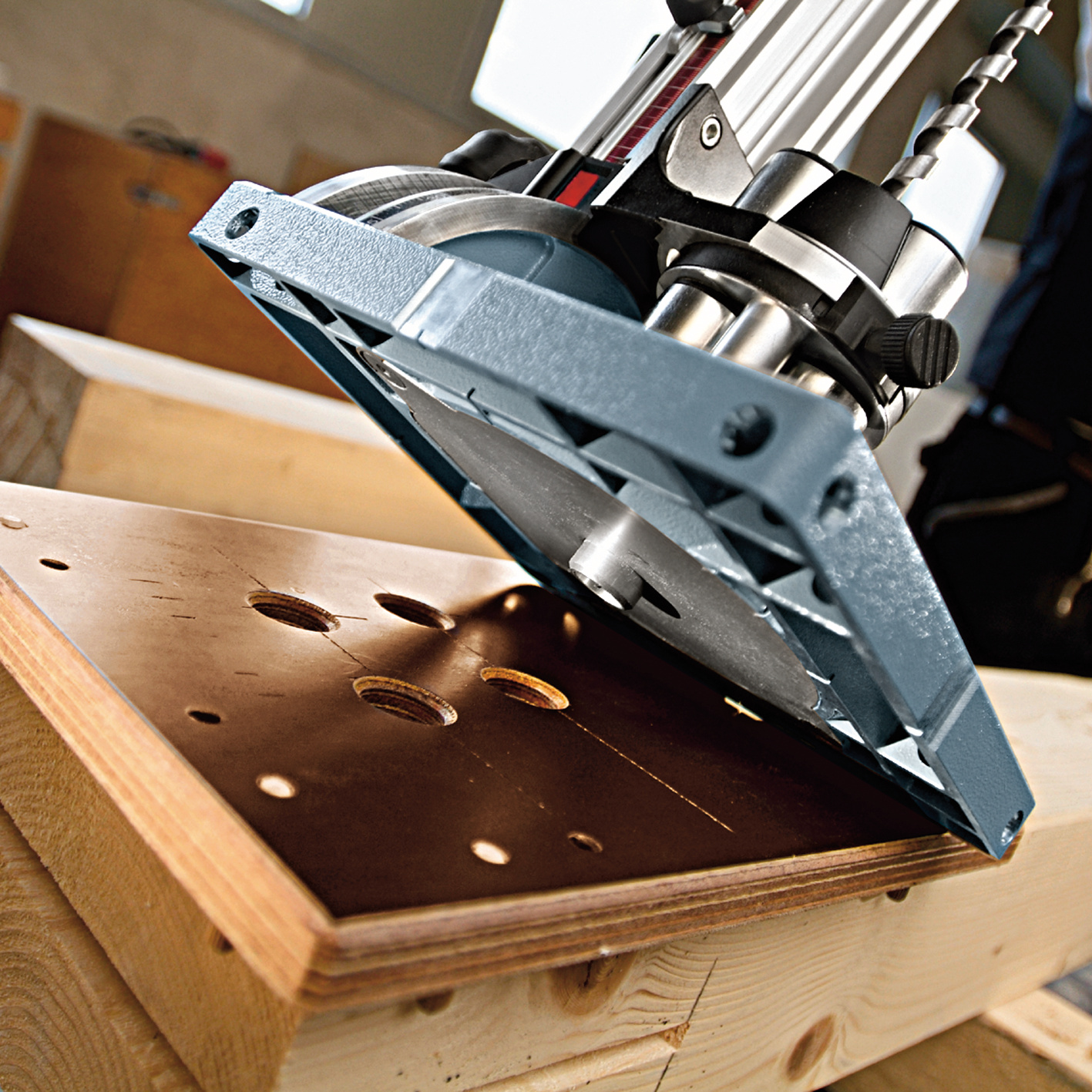

Drilling station BST 460 S

- With stop system thanks to parallel fence (see special accessories)

SEK 7,535.00*

Selling and shipping is done by the Mafell specialist dealer. The Mafell specialist dealer can be selected during the ordering process.

Overview of the Mafell specialist dealers

Delivery time: appr. 10 - 14 workdays

Technical data

| Max. tool diameter at 0° | 130 mm |

| Max. tool diameter at 0° | 5 1/8 in |

| Max. tool diameter at 45° | 100 mm |

| Max. tool diameter at 45° | 3 15/16 in |

| Drill guide clamping range | 8 - 30 mm |

| Drill guide clamping range | 5/16 - 1 3/16 in |

| Tilting adjustment, both sides | 45 ° |

| Collar diameter | 43 mm |

| Collar diameter | 1 11/16 in |

| Max. drill length | 460 mm |

| Max. drill length | 18 1/8 in |

| Max. drilling depth | 265 mm |

| Max. drilling depth | 10 7/16 in |

| Weight | 5 kg |

| Weight | 11.0 lbs |

Product details

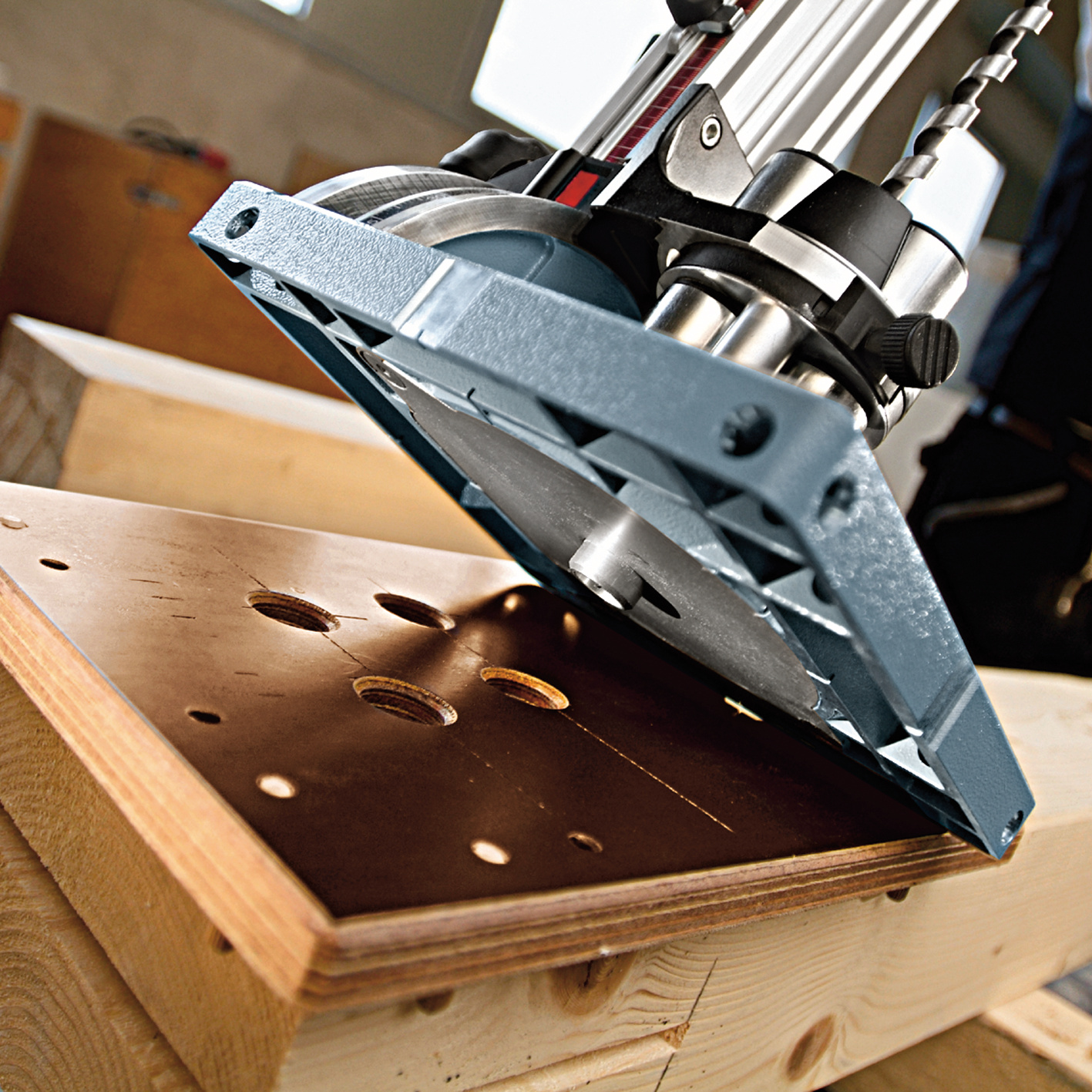

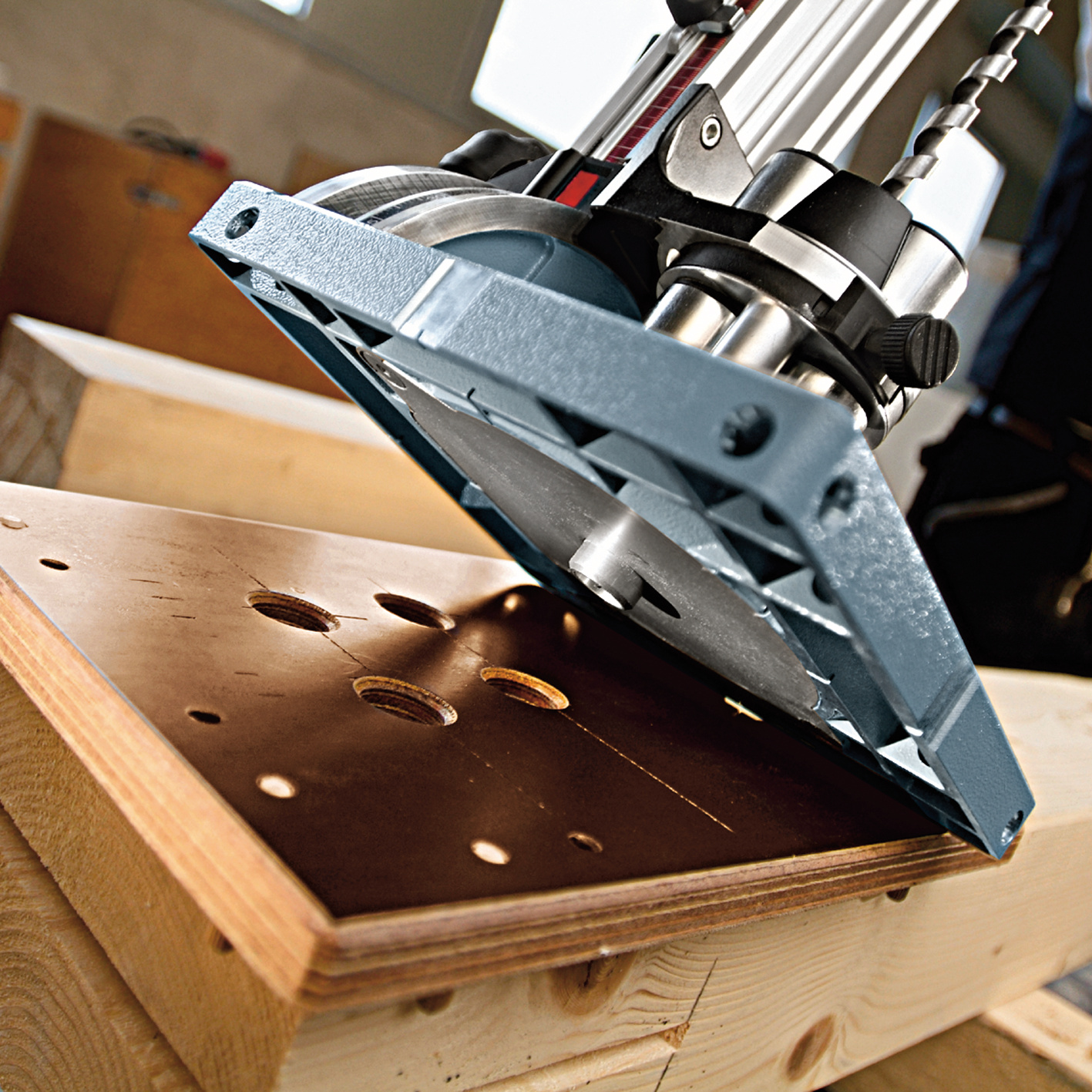

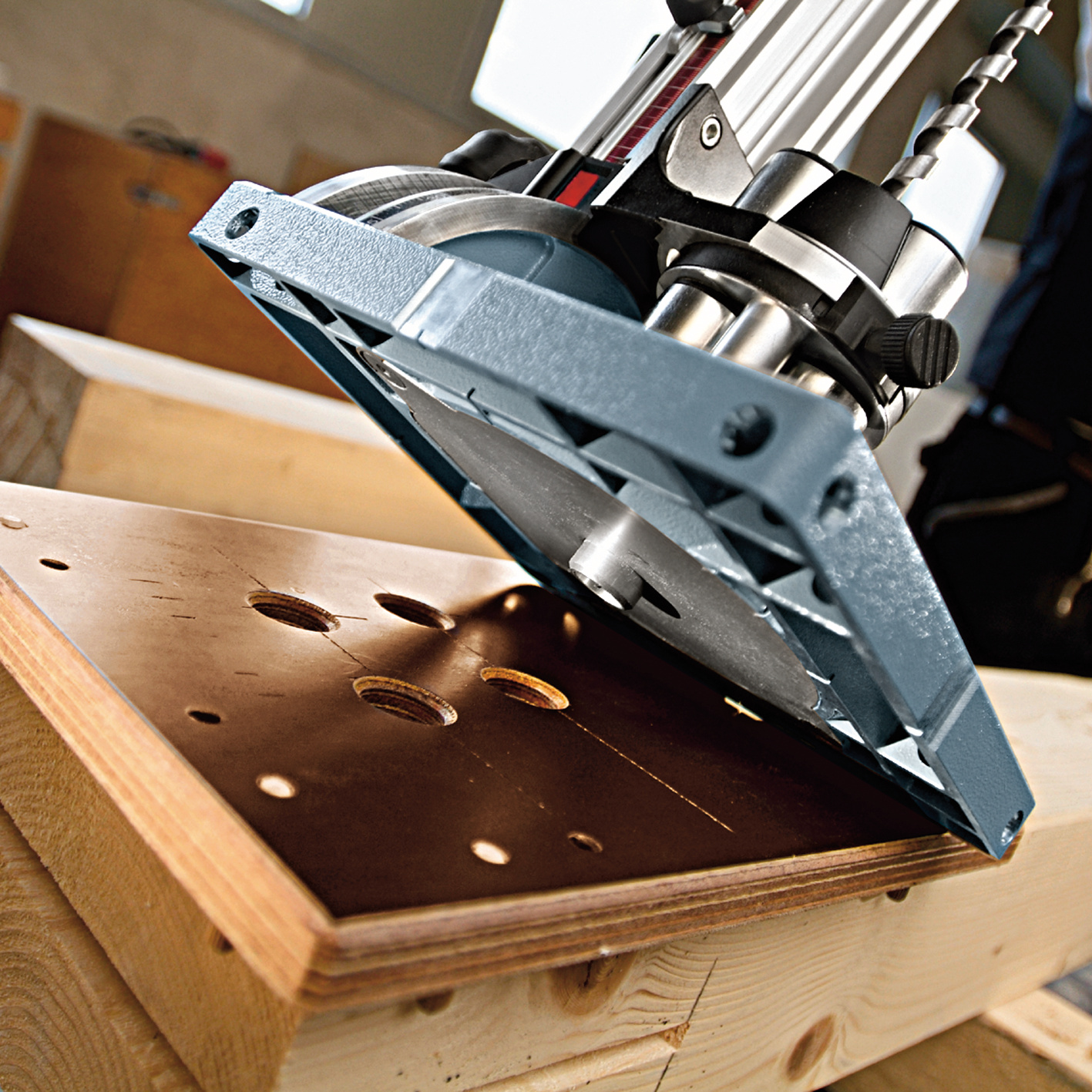

MAFELL´s drilling station not only offers supreme precision, compared with conventional drill jigs, but is also comprehensively revolutionizing drilling operations in solid wood. Its clever design, based on a rugged and lightweight aluminium column, cannot fail to impress.

The single column offers significant benefits: better view of the mark and drill tip, more space for bit changes, and the jamming that can occur during drilling is a thing of the past.

MAFELL is further demonstrating its ability to originate professional solutions, down to the last detail, and its understanding of practical needs. The continuously adjustable drill guide, with six locating elements, enables the drilling station to achieve unprecedented accuracy. As you would expect from MAFELL, the new drilling station is built exclusively from very high-quality materials, so that a long service life is assured.

Applications

- Precision and series drilling

- Angle drilling

- Compatible materials include solid wood and laminated beams

Advantages

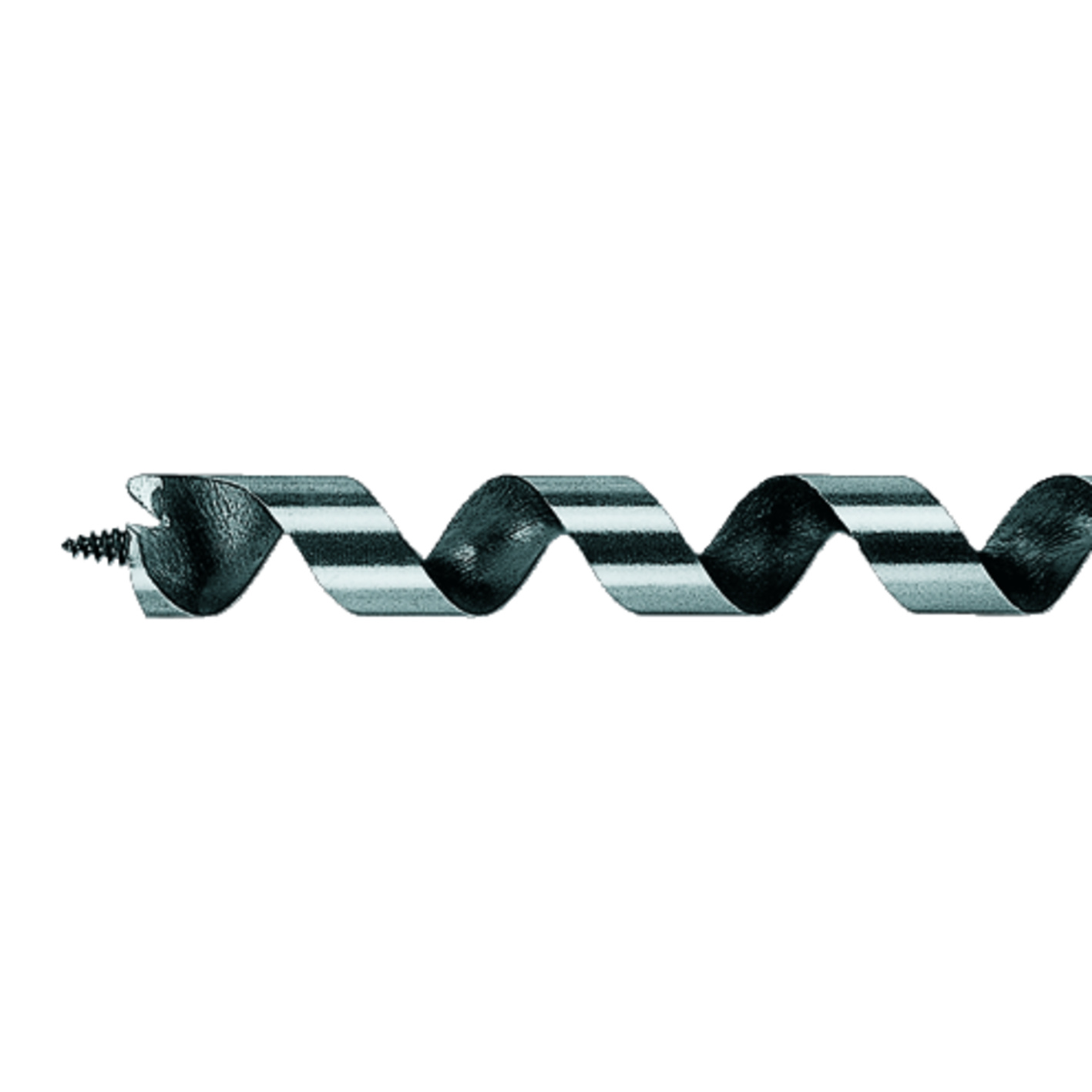

- The 80 mm high drill guide comprises six vertically located rollers with an iris-like adjusting mechanism. They enclose the bit without any backlash and thus provide perfect guidance. This arrangement prevents the bit from drifting.

- The tensile force exerted by the polyethylene cable can be individually adjusted, for example, in order to reduce the feed pressure when working horizontally. Once the hole has been drilled, the machine automatically returns to the starting position.

- The S models can be precisely set to +/- 45° in either direction with the aid of a scale; and locked at 0°. The drill tip – at base plate height – always serves as the pivot axis.

Usage

Downloads / Safety notes

Accessories / Tools

Accessories / Tools

Parallel guide fence

with face edge stop

Drilling machine retainer

Ø 57 mm

Copying insert

24,8 / 18 mm

is accessory of

Google Maps Consent

You don't have enabled the store locator cookies yet. To do so, click on "Open cookie configurator", enable "Store Locator" in the off canvas and click "Save".

This page requires Google Maps to work properly. Click on "Continue" to agree.