Milling motor FM 1000

- 1 Milling motor FM 1000

- 1 Open-ended spanner

- 1 collet chuck OZ 8, 8 mm (5/16 in.)

- 1 Collet nut OZ 8

- 1 Mains cable 4 m (13.1 ft)

- Extremely quiet

- Spindle lock

- Made in Germany

- LED indication for overload

SEK 2,585.00*

SEK 2,915.00* (-SEK 330.00)Selling and shipping is done by the Mafell specialist dealer. The Mafell specialist dealer can be selected during the ordering process.

Overview of the Mafell specialist dealers

Delivery time: appr. 10 - 14 workdays

Technical data

| Dimensions (L x W x H) | 254 x 79 x 73 mm |

| Dimensions (L x W x H) | 10 x 3 1/8 x 2 7/8 in |

| Noise level dB(A) | 74 |

| Universal motor | 230 V / 50 Hz |

| Clamping collar | 43 mm |

| Clamping collar | 1 11/16 in |

| Clamping chuck | 8 mm |

| Clamping chuck | 5/16 in |

| Nominal power input | 1000 W |

| Nominal power input | 1.34 hp |

| Nominal No. of strokes – no load | 4.000 - 25.000 1/min |

| Weight | 1,65 kg |

| Weight | 3.6 lbs |

Product details

With the FM 1000, MAFELL has developed another milling motor “Made in Germany”. The high quality standard and well thought-out details make the MAFELL milling motor the best partner in its performance class.

The speed can be infinitely adjusted to any application. In addition, the digital electronics are equipped with soft start, constant speed under load, idle speed reduction and overload protection.

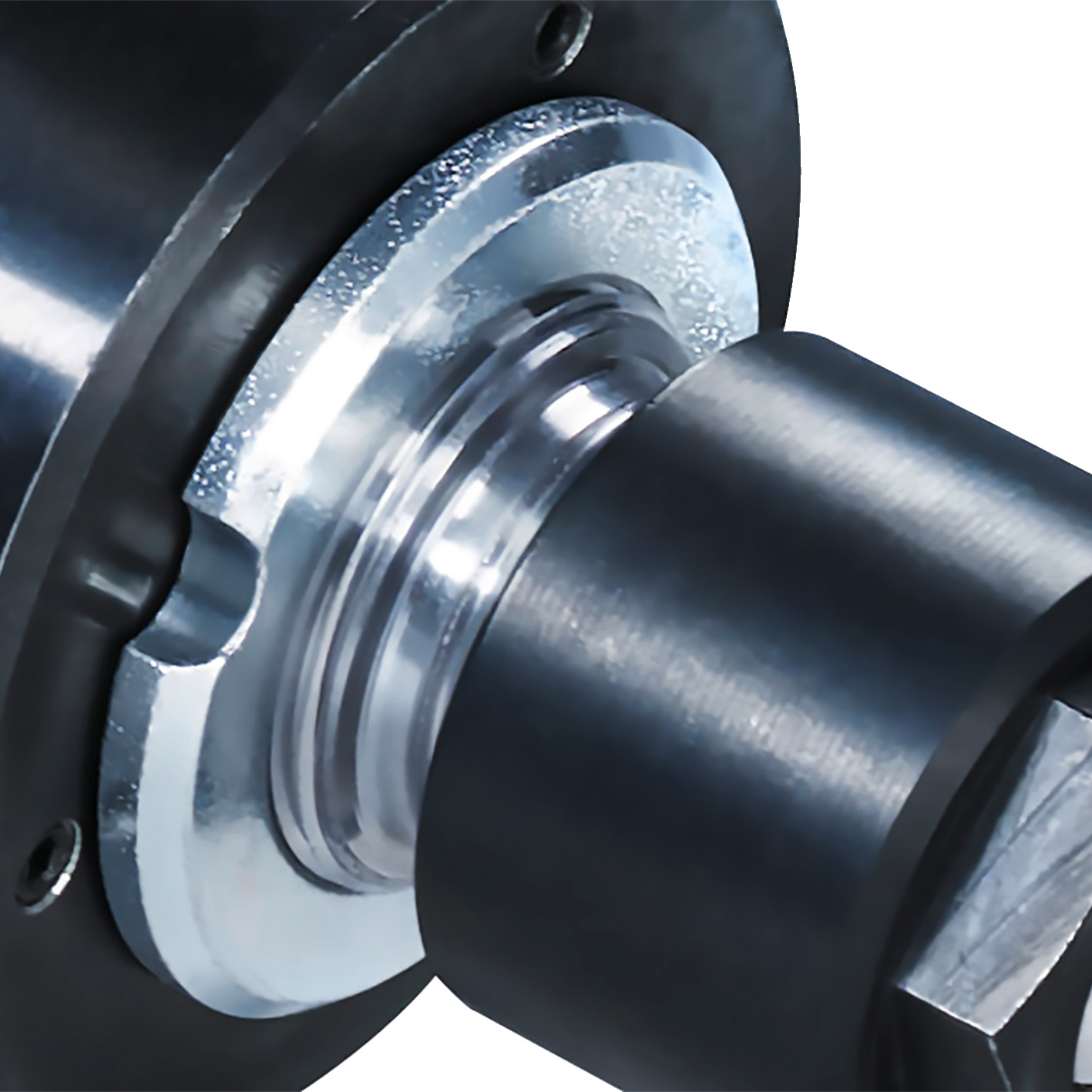

The labyrinth seal of FM 1000 permanently protects the spindle and bearing from even the smallest particles, dust and chips.

Applications

- odel/pattern and mold making, advertising

- Engraving, jewelry,electronics, stone masonry

- Portal milling machines, cutting tables

- Grinding rigs, flexible shafts

- Compatible materials include: wood, metal, plastics foam, polystyrene, stone

Advantages

- The MAFELL milling motors are manufactured under the strictest quality controls in the German town of Oberndorf a. N. Before delivery, each milling motor is “run in” in a test cabin. This increases the tool life and the service life.

- Highest concentricity due to delicate adjustment of all components, such as the double-bearing spindle for absorbing axial forces and the innovative, tool-free quickclamping device.

Usage